Description

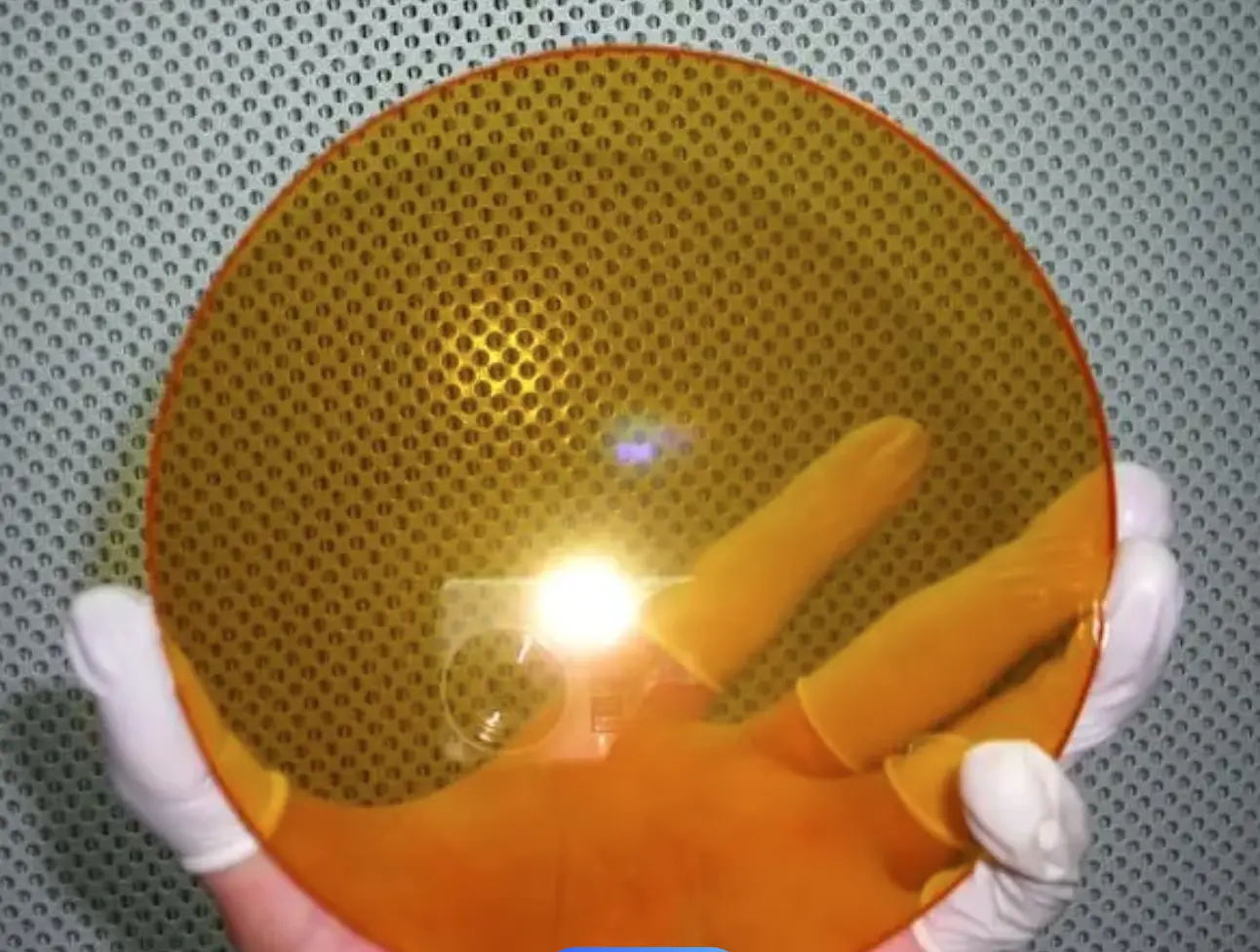

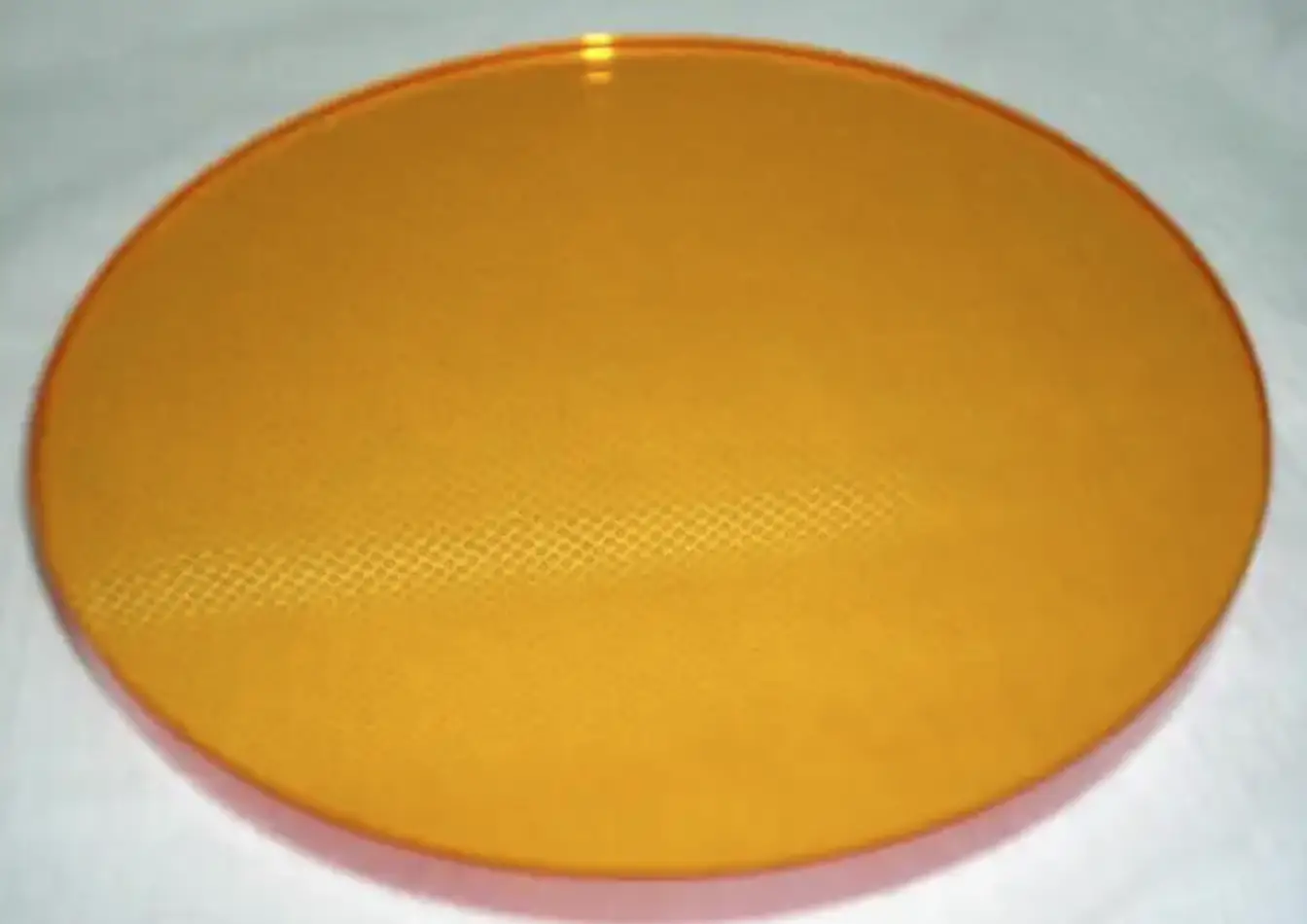

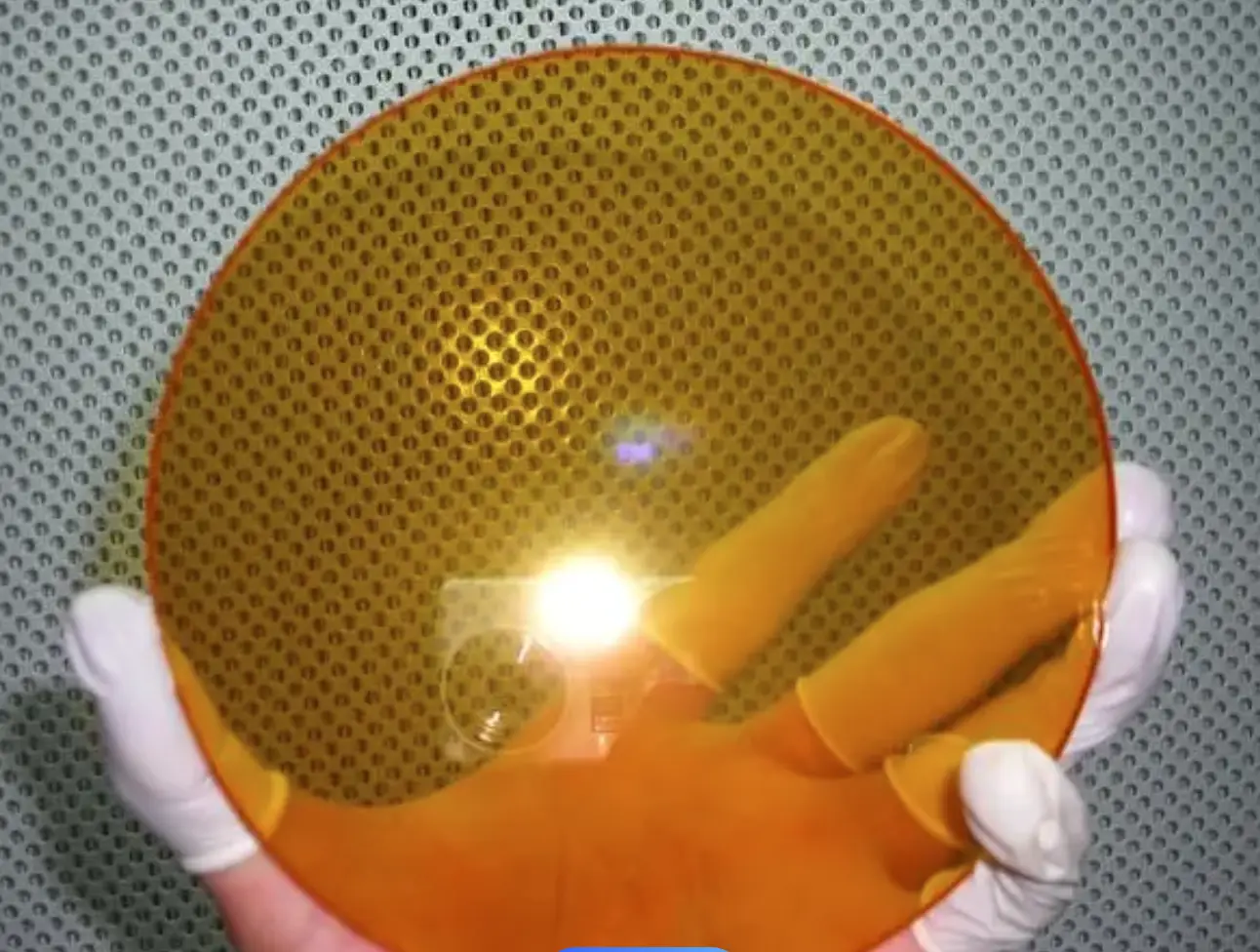

SHAPE OPTICS Zinc Selenide (ZnSe) Protective Window Specifications

| Parameter | Specification |

|---|---|

| Bevel | Protective as needed |

| Clear Aperture CA (mm) | – |

| Clear Aperture (%) | 90 |

| Diameter (mm) | +0.0/-0.1 |

| Thickness (mm) | ±0.1 |

| Coating | BBAR (3000-12000nm) |

| Coating Specification | R_avg <5.0% @ 3 – 12µm |

| Density (g/cm³) | 5.27 |

| Coefficient of Thermal Expansion CTE (10^-6/°C) | 7.57 |

| Edges | Fine Ground |

| Index of Refraction n_d | 2.631 |

| Knoop Hardness (kg/mm²) | 120 |

| Poisson’s Ratio | 0.28 |

| Parallelism (arcmin) | <1 |

| Substrate | Zinc Selenide (ZnSe) |

| Surface Quality | 60-40 |

| Surface Flatness (P-V) | λ/10 @ 10.6µm |

| Type | Protective Window |

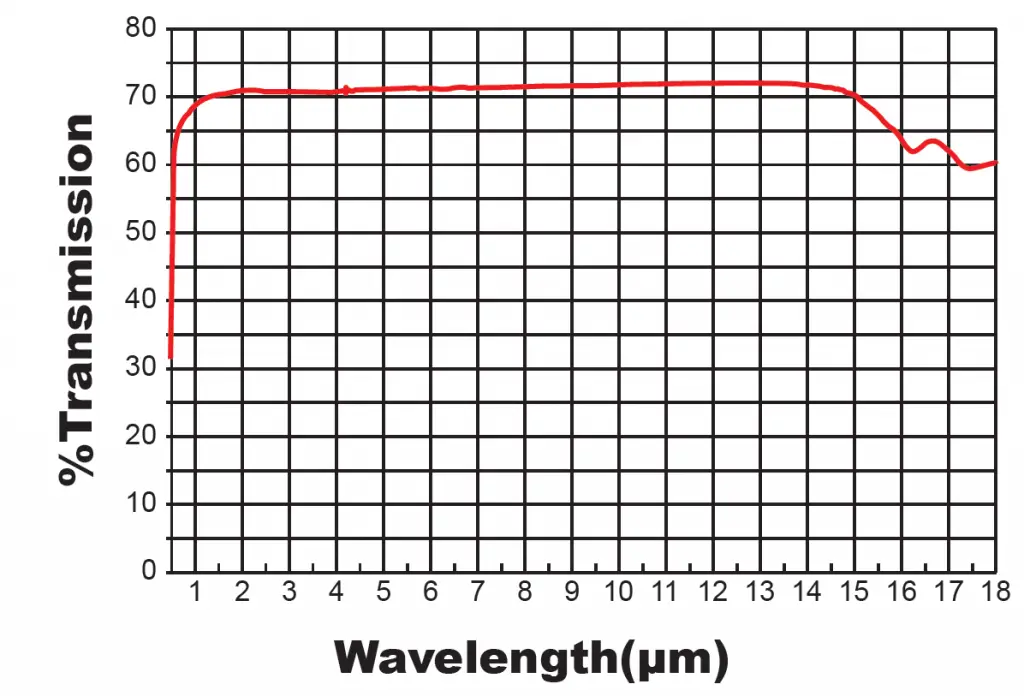

| Wavelength Range (nm) | 3000 – 12000 |

These specifications outline the key parameters and characteristics of SHAPE OPTICS Zinc Selenide (ZnSe) Protective Windows, making them suitable for a wide range of infrared optical applications.

For further assistance with customization or to place an order, please visit our online store or contact our sales team.

Zinc selenide (ZnSe) is a versatile material in optical engineering because of its broad transmission range and specific properties. Here are some key points about it:

- Applications:

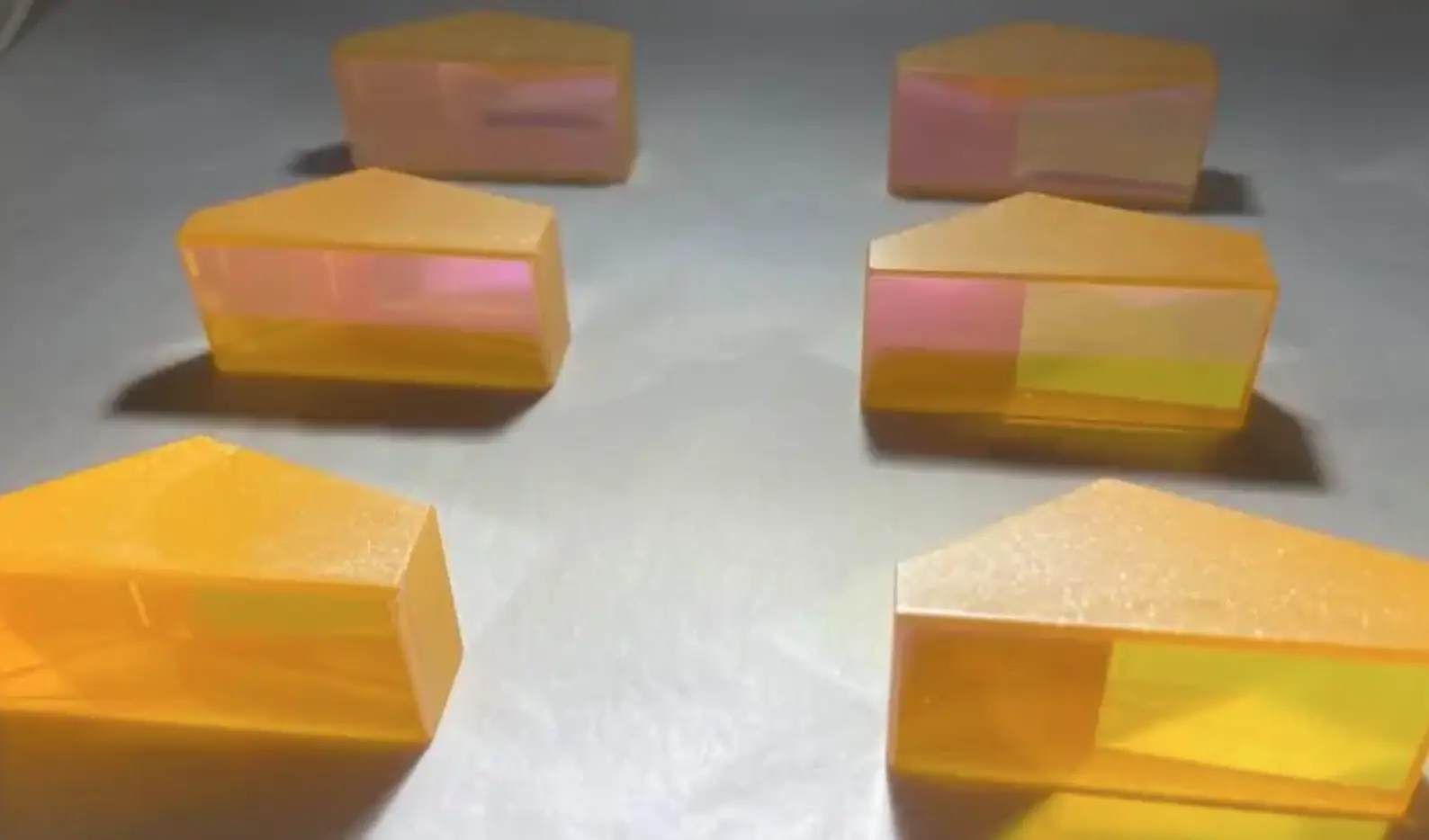

- Infrared Optics: ZnSe is widely used for infrared (IR) applications due to its high transmittance across a broad spectral range, particularly from 0.5 to 22 microns. It is suitable for windows, lenses, mirrors, and prisms.

- CO2 Lasers: It is a preferred material for high-power CO2 laser optics, especially at 10.6 microns, the wavelength at which CO2 lasers operate.

- Manufacturing:

- ZnSe is synthesized by combining zinc vapor and hydrogen selenide gas. The synthesis process allows it to form as sheets on graphite susceptors.

- The material is microcrystalline in structure, and grain size is carefully controlled for optimal mechanical strength.

- Single-crystal ZnSe is also available and used in specific applications where higher purity and uniformity are needed.

These characteristics make ZnSe a sought-after material for high-performance optical applications, especially where thermal durability and broad-spectrum transmittance are required.

Reviews

There are no reviews yet.