Neodymium-doped Yttrium Lithium Fluoride (Nd:YLF) is a notable laser crystal used in various scientific, medical, and industrial applications. Nd:YLF stands out for its unique properties, making it suitable for specific laser operations where certain pulse characteristics and wavelengths are required.

Properties of Nd:YLF:

- Unique Wavelengths: Nd:YLF lasers typically emit light at wavelengths of 1047 nm and 1053 nm for the π- and σ-polarized light, respectively. This provides options for applications that require different wavelengths for optimized performance.

- Pulse Characteristics: Nd:YLF is particularly well-suited for producing short pulses, making it ideal for applications that require high-precision and high peak power, such as in certain types of rangefinders and materials processing equipment.

- Lower Thermal Conductivity: Compared to Nd:YAG, Nd:YLF has a lower thermal conductivity, which can be beneficial in reducing thermal effects in some applications, but may also limit the power output in others.

- High Diode Pump Efficiency: Nd:YLF can be efficiently pumped by laser diodes, which makes it cost-effective in terms of energy consumption and beneficial for compact laser designs.

Applications:

- Precision Materials Processing: The short pulses and specific wavelengths of Nd:YLF make it suitable for precision cutting, drilling, and marking of materials where minimal heat damage is crucial.

- Medical Treatments: Nd:YLF lasers are used in various medical applications, including dermatology and dentistry, where short, controlled laser pulses are required for precise, minimally invasive procedures.

- Scientific Research: In scientific settings, Nd:YLF lasers are used for pump-probe experiments, spectroscopy, and other research applications where pulse characteristics and wavelength tunability are important.

- Laser Ranging and Lidar: The ability to produce short, high-energy pulses makes Nd:YLF suitable for high-resolution laser ranging and Lidar systems used in geology, surveying, and autonomous vehicle navigation.

The manufacturing of Nd:YLF involves doping Yttrium Lithium Fluoride with neodymium ions. This process must be carefully controlled to ensure the uniform distribution of neodymium and the optical quality of the crystal. Nd:YLF lasers continue to be important in applications that benefit from their distinct pulse properties and wavelength options.

Top of Form

Shapeoptics is Able to Offer

- Nd dopand concentration from 0.4% to 1.2% (atm%)

- Er dopand concentration from 0.5% to 3% (mol%)

- Rod diameter from 1mm to 25.4mm

- Length from 1mm to 180mm

- Coating upon your request

Standard Specifications

|

Dopant Concentration Tolerance |

+/- 0.1% |

|

Parallelism / arc seconds |

< 10 |

|

Perpendicularity / arc minutes |

< 5 |

|

Chamfer / mm |

0.1 @45 |

|

Clear Aperture |

95% |

|

Scratch and Dig |

10/5 |

|

Surface Flatness | Lambda/10 @633nm |

|

Wavefront Distortion | Lambda /10 @633nm (Dia < 7mm)Lambda /8 @633nm (Dia ≥ 7mm) |

|

Damage Threshold / J.cm-2 |

> 15 (TEM00, 10ns, 10Hz) |

Optical Properties

|

Peak Stimulated Emission Cross Section / cm2 |

1.2 x 10-19 @1053 nm (E // a-axis) 1.81 x 10-19 @1047 nm (E // a-axis) |

|

Transparency Region / m |

0.18 ~ 6.7 |

|

Spontaneous Fluorescence Lifetime / s |

485 s for 1% Nd |

|

Scatter Losses / cm-1 |

< 0.2% |

|

Peak Absorption Coefficient (1.2% Nd) / cm-1 |

a=3.59 @797 nm (E ⊥ c-axis) a=10.8 @792 nm (E // c-axis) |

Physical Properties

|

Chemical Formula |

LiY1.0xNdxF4 |

|

Crystal Structure |

Tetragonal System |

|

Lattice Constants / A |

a=5.16, c=10.85 |

|

Concentration / cm3 |

~ 1.4 x 1020 for 1% Nd doped |

|

Density / g.cm3 |

3.99 |

|

Melting Point / ℃ |

819 |

|

Knoop Hardness / Kg.mm2 |

300 |

|

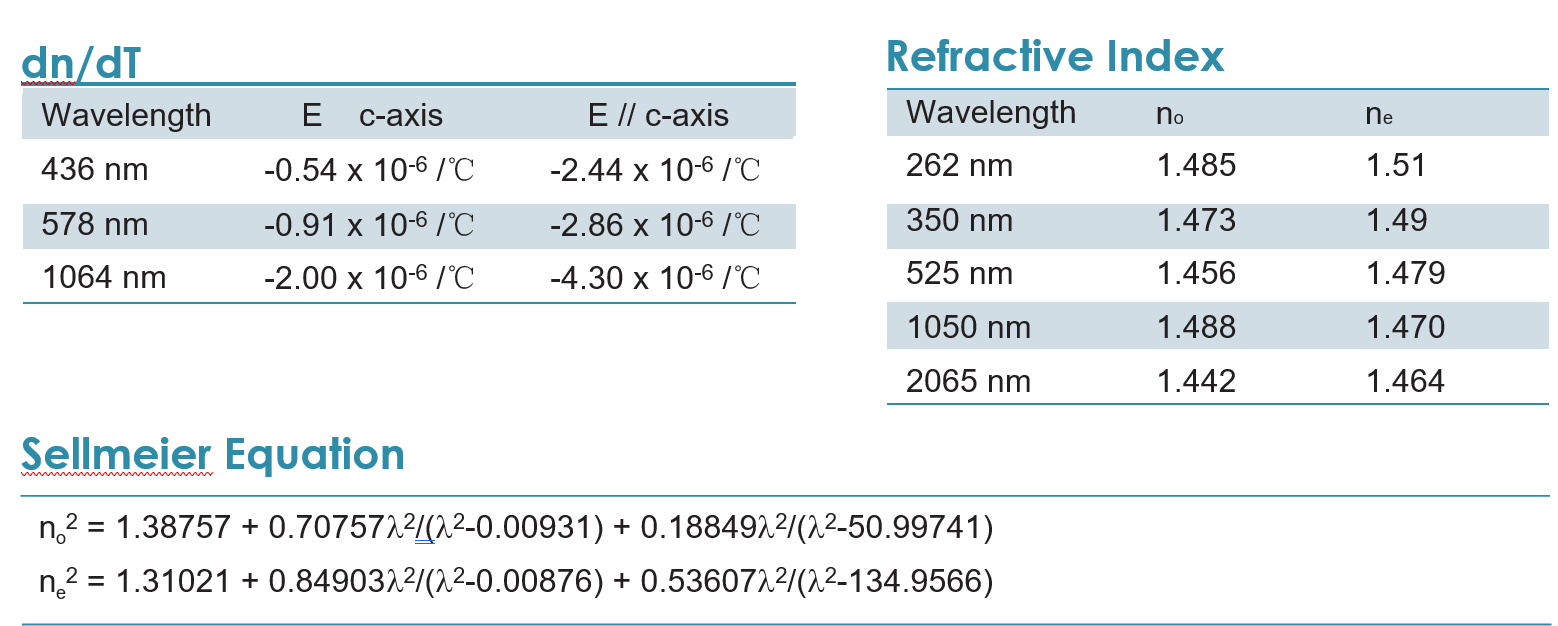

Refractive Index |

1.82 |

|

Thermal Expansion Coefficient / K-1 |

8.3 x 10-6 parallel c-axis |

|

Thermal Conductivity / W.cm-1K-1 |

0.063 |

|

Specific Heat / J.g-1K-1 |

0.79 |

Neodymium doped Yttrium Lithium Fluoride (Nd:YLF) is a good performance laser crystal, with low thermal lensing effect and high power. We can offer Nd, Pr, Er, Tm, Ho and no doped YLF crys- tals performing the specifications upon your request.

Shapeoptics offers a comprehensive range of materials and advanced equipment for custom and OEM optical components, leveraging over 20 years of expertise in manufacturing lenses, prisms, windows, and more. We utilize high-quality materials like UV and IR grade fused silica, Germanium, and ZnSe, among others. Our state-of-the-art techniques and equipment minimize waste and optimize delivery times. Our in-house capabilities include standard and custom coatings across the UV-NIR spectrum, ensuring high quality and compliance with all industry standards. For precision and reliability in optics, contact Shapeoptics for your next project.