Shape Optics offers high-performance Short Pass Filters engineered to transmit wavelengths shorter than a defined cutoff while blocking longer wavelengths with high optical density. These filters are essential for applications that require precise wavelength selection, such as fluorescence excitation, thermal/IR rejection, and optical color separation.

Manufactured using advanced multi-layer dielectric coating technology, SOT short pass filters provide high transmission, steep cutoff slopes, and deep blocking (OD>4). Built on optical glass or fused silica substrates, they deliver excellent durability and consistent performance in both research and industrial optical systems.

Features

- High Transmission in Passband: Delivers >85% transmission below the cutoff wavelength while effectively blocking longer wavelengths.

- Precise Cutoff Control: Features a sharp spectral edge (90%–10% < 10 nm) for accurate wavelength separation in precision optical systems.

- Broad Application Versatility: Widely used in fluorescence instrumentation, heat rejection, and color filtering across UV, VIS, and IR ranges.

- Durable & Environmentally Stable: Multi-layer dielectric coatings ensure long-term stability in laboratory, industrial, and field environments.

- Customizable Designs: Available with custom cutoff wavelengths, sizes, and substrates to match specific system requirements.

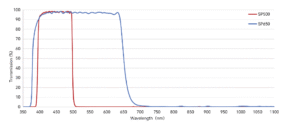

Spectrum Transmission

Standard cutoff wavelengths are available for common applications.

If standard products do not meet your needs, custom short pass filters can be designed to your exact cutoff wavelength, bandwidth, blocking level, size, and substrate.

Typical Shortpass Filters

| Model | Cut-off Wavelength (nm) | Transmittance | Wavelength (nm) | Optical Density |

|---|---|---|---|---|

| NH-SP500 | 500 ± 10 | T ≥ 90% | 410–480 | OD ≥ 2 @ 540–1100 |

| NH-SP520 | 520 ± 10 | T ≥ 90% | 410–500 | OD ≥ 2 @ 560–1100 |

| NH-SP600 | 600 ± 10 | T ≥ 90% | 410–580 | OD ≥ 2 @ 640–1100 |

| NH-SP635 | 635 ± 10 | T ≥ 90% | 410–615 | OD ≥ 2 @ 675–1100 |

| NH-SP640 | 640 ± 10 | T ≥ 90% | 410–620 | OD ≥ 2 @ 680–1100 |

| NH-SP645 | 645 ± 10 | T ≥ 90% | 410–625 | OD ≥ 2 @ 685–1100 |

| NH-SP650 | 650 ± 10 | T ≥ 90% | 410–630 | OD ≥ 2 @ 690–1100 |

| NH-SP655 | 655 ± 10 | T ≥ 90% | 410–635 | OD ≥ 2 @ 695–1100 |

| NH-SP660 | 660 ± 10 | T ≥ 90% | 410–640 | OD ≥ 2 @ 700–1100 |

| NH-SP670 | 670 ± 10 | T ≥ 90% | 410–650 | OD ≥ 2 @ 710–1100 |

| NH-SP700 | 700 ± 10 | T ≥ 90% | 410–680 | OD ≥ 2 @ 740–1100 |

| NH-SP720 | 720 ± 10 | T ≥ 90% | 410–700 | OD ≥ 2 @ 760–1100 |

| NH-SP730 | 730 ± 10 | T ≥ 90% | 410–710 | OD ≥ 2 @ 770–1100 |

| NH-SP735 | 735 ± 10 | T ≥ 90% | 410–715 | OD ≥ 2 @ 775–1100 |

| NH-SP740 | 740 ± 10 | T ≥ 90% | 410–720 | OD ≥ 2 @ 780–1100 |

| NH-SP750 | 750 ± 10 | T ≥ 90% | 410–730 | OD ≥ 2 @ 790–1100 |

| NH-SP760 | 760 ± 10 | T ≥ 90% | 410–740 | OD ≥ 2 @ 800–1100 |

| NH-SP770 | 770 ± 10 | T ≥ 90% | 410–750 | OD ≥ 2 @ 810–1100 |

| NH-SP780 | 780 ± 10 | T ≥ 90% | 410–760 | OD ≥ 2 @ 820–1100 |

| NH-SP800 | 800 ± 10 | T ≥ 90% | 410–780 | OD ≥ 2 @ 840–1100 |

| NH-SP810 | 810 ± 10 | T ≥ 90% | 410–790 | OD ≥ 2 @ 850–1100 |

| NH-SP820 | 820 ± 10 | T ≥ 90% | 410–800 | OD ≥ 2 @ 860–1100 |

| NH-SP830 | 830 ± 10 | T ≥ 90% | 410–810 | OD ≥ 2 @ 870–1100 |

| NH-SP835 | 835 ± 10 | T ≥ 90% | 410–815 | OD ≥ 2 @ 875–1100 |

| NH-SP850 | 850 ± 10 | T ≥ 90% | 410–830 | OD ≥ 2 @ 890–1100 |

| NH-SP860 | 860 ± 10 | T ≥ 90% | 410–850 | OD ≥ 2 @ 920–1100 |

| NH-SP870 | 870 ± 10 | T ≥ 90% | 410–860 | OD ≥ 2 @ 930–1100 |

| NH-SP880 | 880 ± 10 | T ≥ 90% | 410–870 | OD ≥ 2 @ 950–1100 |

| NH-SP890 | 890 ± 10 | T ≥ 90% | 410–880 | OD ≥ 2 @ 960–1100 |

| NH-SP900 | 900 ± 10 | T ≥ 90% | 410–890 | OD ≥ 2 @ 970–1100 |

| NH-SP910 | 910 ± 10 | T ≥ 90% | 410–900 | OD ≥ 2 @ 980–1100 |

| NH-SP920 | 920 ± 10 | T ≥ 90% | 410–910 | OD ≥ 2 @ 990–1100 |

| NH-SP930 | 930 ± 10 | T ≥ 90% | 410–920 | OD ≥ 2 @ 1000–1100 |

| NH-SP940 | 940 ± 10 | T ≥ 90% | 410–930 | OD ≥ 2 @ 1010–1100 |

| NH-SP950 | 950 ± 10 | T ≥ 90% | 410–940 | OD ≥ 2 @ 1020–1100 |

Additional models are available upon requested.

Applications

- Fluorescence Instrumentation – Select excitation wavelengths while blocking emission or background light

- Heat Rejection – Block IR wavelengths while passing visible light (e.g., projection systems)

- Color Filtering – Improve contrast and image quality in optical imaging systems

- Scientific & Industrial Optics – Precise wavelength management across UV, VIS, and IR bands

Need a custom shortpass filter?

Contact us with your requirements and operating conditions for a tailored solution.