Sequential tolerance analysis is the process by which the effects of manufacturing defects and alignment errors are considered.

Let us assume that our task is to design a laser beam expander for volume production. An Argon-ion laser beam of 2.5 mm 1/e2 full width is to be expanded x3, and the resulting wavefront error must not exceed 1/20 RMS over two full beam widths (i.e. measured over a total beam diameter of 5 mm).

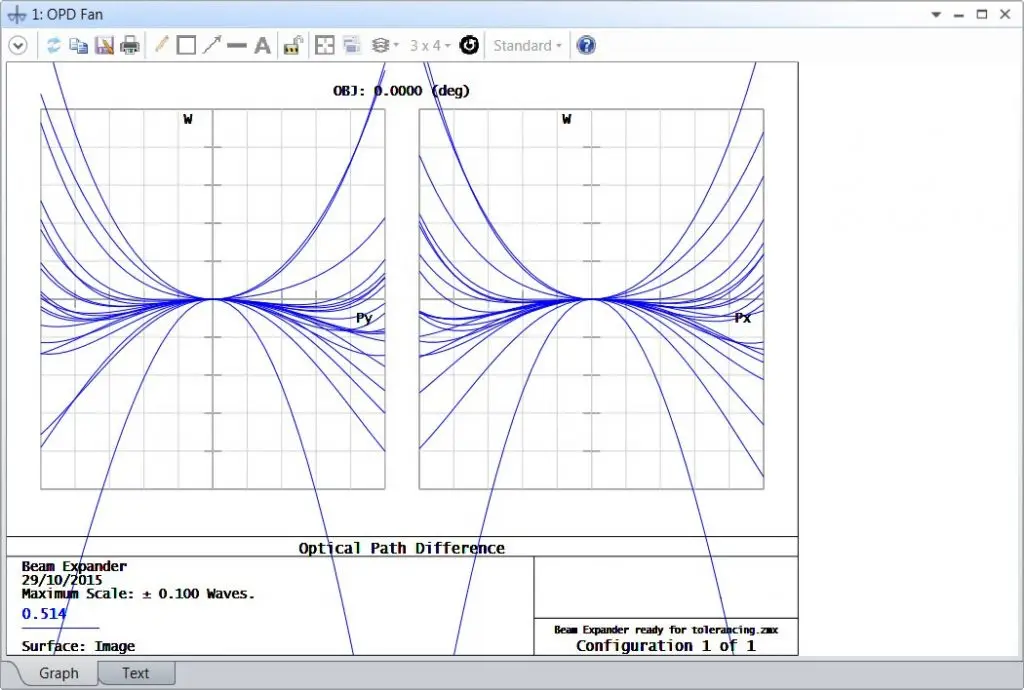

The nominal system performance greatly exceeds that required in production:

Tolerancing is about accounting for manufacturing error, so that the ‘as built’ design meets its intended specification.

We will use this in conjunction with the Monte Carlo feature soon. Then, re-open the tolerancing dialog box. Press Reset to undo the changes we made and restore the default settings. The Set-Up tab shows:

As we chose to overlay Monte Carlo graphics, and had an open OPD plot on the desktop, the resulting OPDs of the 20 Monte Carlo files can be clearly seen: we are a long way from our target performance of 0.05 waves RMS (1/20)!

Tolerancing is a complex procedure that requires a lot of iteration. In general, you should start by making sure the design is optimized to reasonably exceed the target specification.

Reference Source: https://www.zemax.com/