Flame Detector Filters are engineered to deliver accurate and reliable flame detection in industrial and domestic combustion systems. These filters selectively transmit infrared radiation emitted by flames while effectively blocking background radiation and interference from non-flame sources.

By combining high transmission with a steep spectral edge, flame detector filters enhance sensor sensitivity and detection accuracy. They are optimized for real-time flame monitoring in systems such as industrial heaters, drying ovens, gas turbines, burners, and combustion chambers, where safety and performance are critical.

Available in multiple cut-on wavelengths, these filters are designed to match characteristic flame emission bands, ensuring dependable detection across a wide range of combustion environments.

Key Features

- High Transmission Efficiency – Ensures strong flame signal detection within defined IR wavelength bands

- Sharp Spectral Slope – Precisely defines flame wavelength boundaries for accurate detection

- Wide Industrial Compatibility – Suitable for heating systems, drying equipment, and gas turbines

- Durable Construction – Designed for long-term reliability in harsh industrial environments

- Customizable Designs – Multiple cut-on wavelengths and transmission bands available

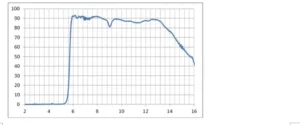

Spectrum Transmission

Standard spectral designs are available for common flame detection wavelengths. If standard options do not meet your system requirements, custom transmission curves can be developed to match specific cut-on wavelengths, bandwidths, and blocking levels.

Coating Quality & Environmental Reliability

All flame detector filters undergo stringent testing to meet military and industrial standards:

- Adhesion Test (MIL-C-675C) – No blistering or peeling after repeated tape removal

- Thermal Cycling – −62°C to +71°C with no coating detachment

- Abrasion Resistance (MIL-C-675C / CCC-C-440) – No surface damage after 25 cycles at 1.0 lb load

- Humidity Test – 95–100% RH at 49°C for 24 hours with no defects

- Solvent Resistance – Stable after acetone and alcohol exposure

- Salt Spray Test – 100 hours at 35°C, 5% salt concentration with no coating damage

Standard Specifications

| Cut-On Wavelength (µm) | Transmission Band | Transmission |

|---|---|---|

| 3.2 ± 1% | 3.48 – 3.55 µm | T > 90% |

| 5.5 ± 1% | 6.3 – 14 µm | T > 90% |

| 7.3 ± 0.1% | 7.8 – 11 µm | T > 90% |

Additional wavelength options available upon request.

Typical Applications

- Gas-Fueled Cookers – Domestic and industrial flame monitoring

- Industrial Heating & Drying Systems – Real-time flame supervision

- Domestic Heating Systems – Improved safety and operational efficiency

- Industrial Gas Turbines – Flame presence and stability monitoring

- Combustion & Burner Systems – Reliable detection in furnaces and chambers