Coatings are an increasingly critical component of complex optical systems such as microscopes, telescopes, cameras, and lasers, to predict and evaluate the real coating impacts/effects before fabrication is becoming more important to an optical designer. This article has demonstrated how to use common Anti-Reflection coatings for common spectral bands in an optical system. In practice, optics designs coatings for each customer application, accounting for wavelength or wavelength band, polarization states, angles of incidence, required durability, and more. Shapeoptics provides custom coatings for more than just Anti-Reflection needs, such as reflectors, beamsplitters, and dichroics.

For an example of the use and performance of these anti-reflection coatings, refer to the the design as below:

You can find the names of the available coatings in the encrypted coatings section in ZEMAX.

This design contains singlet lens for coupling light between two single mode fibers and provides a useful example of how the application of coatings can affect the performace of an optical system. The front and back surfaces of the lens have an anti-reflective coating. Each configuration is a different coating and the screenshots below show how the coatings change the amount of light reflected at the lens faces.

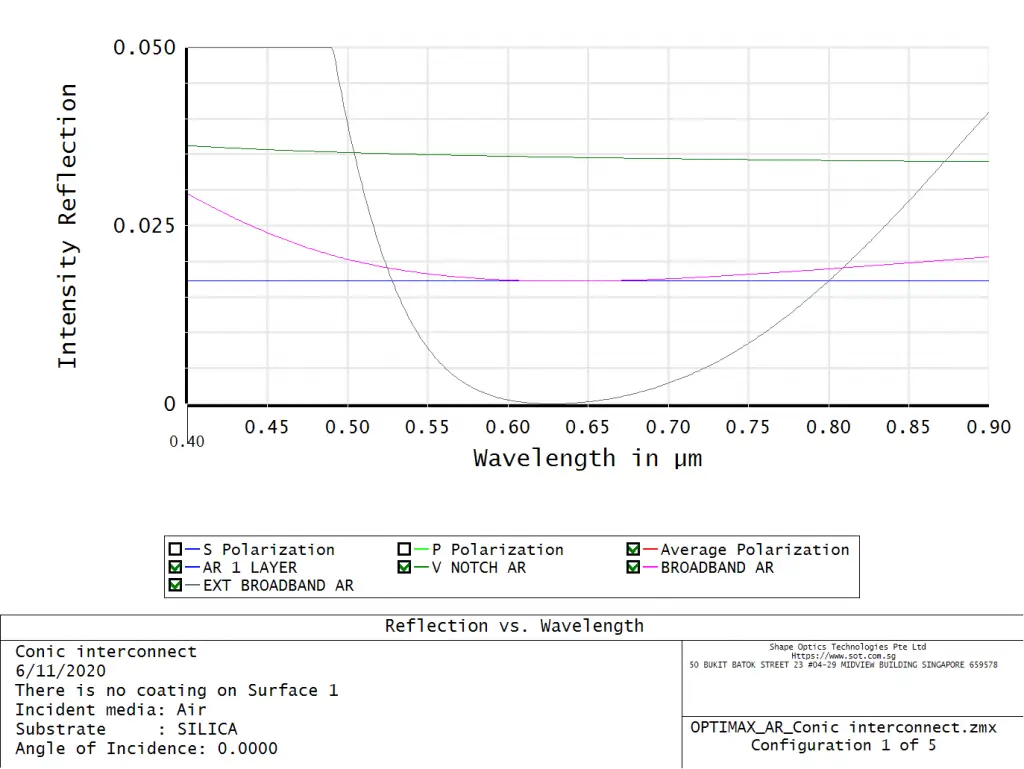

The figure below shows a comparison between the different configurations. The different configurations includes different coating recipe from OPTIMAX-which shapeoptics could provide similar performance.

Description of Anti-Reflection coatings

- OPTIMAX‐SLMGF2-This is a single layer of magnesium fluoride, creating the simplest Anti-Reflection (AR) coating.

- OPTIMAX‐Vxxx‐1_N-These are V notch AR coatings, which are designed for a specific wavelength and are thus higher performing than the SLMGF2 layer

- OPTIMAX‐VISBBAR‐1_N-These are Broadband AR coatings designed to perform over the wavelength range 400‐700 nm.

- OPTIMAX‐XBBAR‐1_N-These are Broadband AR coatings designed to perform over and extended range 450‐900 nm.