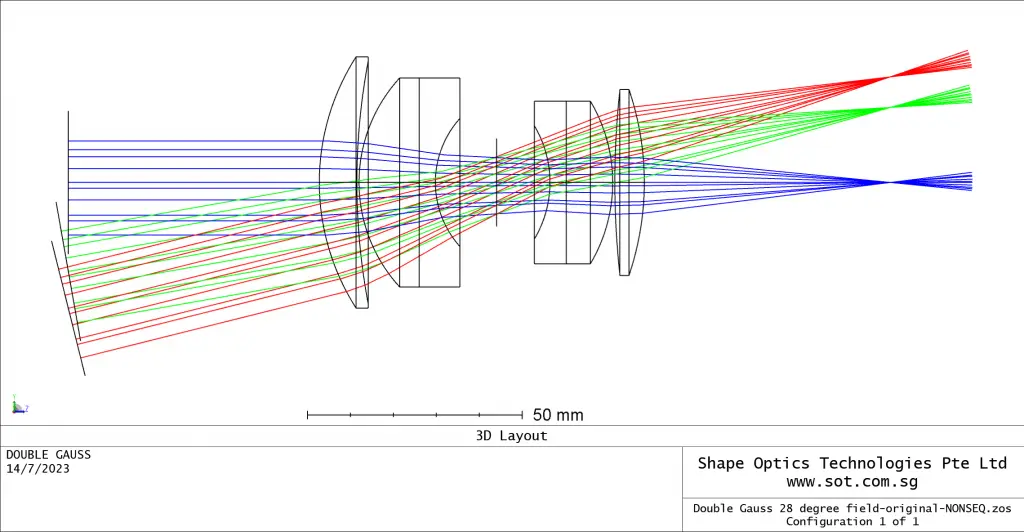

In this example, a Double Gauss lens with a 28° field of view is used to demonstrate the optical algorithm for converting sequential surfaces into non-sequential objects.

Important Note: Do not assume that this optical algorithm will perfectly reproduce your sequential model. Always verify the converted non-sequential system before performing any critical analysis.

Sequential-to-Non-Sequential Conversion Algorithm

The conversion proceeds as follows:

1. Insert Non-Sequential Infrastructure

A Non-Sequential Component (NSC) surface and a dummy exit port surface are inserted. The exit port is positioned to coincide with the final surface in the selected conversion range.

2. Convert Sequential Surfaces

The selected range of sequential surfaces is converted into:

- NSC surface objects for standalone surfaces and mirrors with zero substrate thickness

- NSC solid objects for pairs of surfaces with a material between them, or mirrors with non-zero substrate thickness

3. Replace Coordinate Breaks

Coordinate breaks are replaced with null objects that replicate the same rotations. All subsequent objects reference these null objects to preserve alignment.

4. Delete Original Sequential Surfaces

Once conversion is complete, the original sequential surfaces within the selected range are removed.

5. Optional: Convert Entire File to Non-Sequential Mode

If “Convert file to non-sequential mode” is enabled:

- The system switches to non-sequential mode

- Any sequential surfaces outside the selected range are deleted

6. Optional: Add Sources and Detectors

If “Add Sources & Detectors” is enabled:

- Each sequential field is converted into a Source Ellipse

- Source parameters are derived from the sequential field coordinates and the Entrance Pupil Diameter

7. Detector Placement Based on Image Centroids

For each field:

- The centroid location at the IMAGE surface is computed using the Spot Diagram analysis

- A Detector Rectangle is placed at each centroid

- Detector size matches the default Spot Diagram display width with “Show Airy Disk” enabled

- Each detector is labeled with the corresponding field number

a. Flat Image Plane (Focal Systems)

All Detector Rectangles lie in the same XY plane. If detectors overlap, ray visibility may be affected due to the nesting rule. In such cases, detectors should be manually offset along the optical axis by more than the Glue Distance defined in the System Explorer.

b. Curved Image Surfaces

Although curved IMAGE surfaces are not converted into curved detectors, detector positions account for surface sag and local surface normals at each field centroid.

c. Afocal Image Space

When Afocal Image Space is enabled:

- Rays are assumed to be nearly collimated at the IMAGE surface

- RMS spot sizes are typically large, resulting in large Detector Rectangles

- To avoid overlap, detectors are offset incrementally along the optical axis by distances slightly exceeding the Glue Distance

- This offset does not significantly affect results for nearly collimated beams

A Detector Color is also added after the Detector Rectangle(s), offset by more than the Glue Distance. Its size matches the default display width of the Full Field Spot Diagram analysis.

Finite-Conjugate Imaging Systems

For focal systems where the OBJECT is at a finite distance (not infinity):

8. Add Source DLL and Slide Object

An inactive “Lambertian Overfill” Source DLL and a Slide Object are inserted just before the Source Ellipses.

a. Object Size Definition

Their dimensions are based on the Clear Semi-Diameter of the OBJECT surface.

b. Lambertian Overfill Behavior

The Source DLL:

- Overfills the first system aperture with a Lambertian angular distribution

- Uses the Target Distance and Target Diameter to define the virtual aperture

- Assumes a circular target aperture

- Uses a square source area matching the Slide Object dimensions

c. Ray Generation

Rays originate uniformly across the square source area. A circular cone is fitted to the target aperture, and ray directions are randomly selected within this cone. Since the cone slightly exceeds the target aperture’s elliptical cross-section, minor overfilling typically occurs.

Image Surface with Material Defined

9. Image Surface Material Handling

If the IMAGE surface has a material defined:

- An additional NSC object is created starting at the IMAGE surface location

- The back face radius and aperture match the front face

- The object thickness is set to 1 lens unit

a. Detector Ambiguity

Because this additional object introduces ambiguity in detector placement, the following are not added during conversion:

- Source DLL

- Slide Object

- Detector Color

In this case, the file is converted to non-sequential mode without these elements.

Final Notes and Limitations

11. File Overwrite Warning

Unless “Save New System As…” is enabled, the converted non-sequential system will overwrite the original sequential file. This action cannot be undone.

Conversion Limitations

This optical algorithm may not work correctly in all configurations. In some cases, it may be necessary to insert dummy surfaces with small spacings before or after the conversion range to ensure robust object creation and ray propagation.