Description

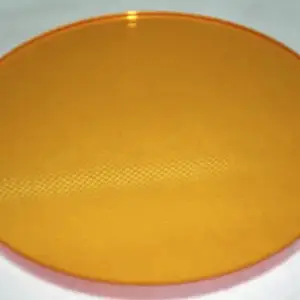

Shape Optics Zinc Sulfide (ZnS) Clear Grade Protective Window Specifications

| Parameter | Specification |

|---|---|

| Bevel: | Protective as needed |

| Clear Aperture CA (mm): | – |

| Clear Aperture (%): | 85 |

| Diameter (mm): | – +0.00/-0.13 |

| Thickness (mm): | ±0.13 |

| Coating: | Uncoated |

| Density (g/cm³): | 4.08 |

| Coefficient of Thermal Expansion CTE (10^-6/°C): | 6.8 |

| Edges: | Fine Ground |

| Index of Refraction n_d: | 2.371 |

| Knoop Hardness (kg/mm²): | 210 |

| Poisson’s Ratio: | 0.27 |

| Parallelism (arcmin): | <3 |

| Substrate: | Zinc Sulfide, Clear Grade |

| Surface Quality: | 60-40 |

| Surface Flatness (P-V): | λ/20 @ 10.6µm |

| Type: | Protective Window |

| Wavelength Range (nm): | 400 – 12000 |

| Young’s Modulus (GPa): | 74.5 |

| Model Number: |

Material Characteristics

- Chemical Vapor Deposition (CVD):

- ZnS is produced using the CVD process, resulting in a high-purity material with excellent optical properties and mechanical strength.

- Optical Performance:

- Transmission: High transmittance from visible to infrared wavelengths (0.4 – 12 µm).

- Scatter: Low scatter ensures high-quality imaging and accurate sensor readings.

- Mechanical and Chemical Properties:

- Hardness: Moderately hard, offering better durability than ZnSe.

- Chemical Stability: Resistant to most acids and alkalis, with better chemical durability compared to ZnSe.

Applications

- Imaging Systems:

- Dual Spectrum Imaging: Suitable for systems featuring both visible and thermal imaging paths.

- Thermal Cameras: Used in thermal imaging cameras for clear IR transmission.

- Military and Defense:

- Night Vision: Employed in night vision equipment that requires high IR transmittance and durability.

- Missile Guidance: Used in missile guidance systems where both visible and IR sensors are needed.

- Industrial Sensing:

- Environmental Monitoring: Ideal for sensors in environmental monitoring that detect infrared wavelengths.

- Gas Detection: Used in industrial gas detection systems operating in the infrared spectrum.

- Scientific Research:

- Spectroscopy: Used in spectroscopic applications requiring high transmittance across a broad range of wavelengths.

- Medical Imaging:

- Infrared Thermography: Applied in medical imaging systems such as IR thermography, which benefit from ZnS’s low absorption and scatter properties.

Shape Optics Zinc Sulfide (ZnS) Windows offer a robust solution for a wide range of optical applications, particularly those requiring low absorption and scatter across a broad wavelength range. Their enhanced durability and chemical resistance make them a superior choice compared to Zinc Selenide, especially in systems that incorporate both visible and infrared sensors.