Key Features

- Material: Fused Silica and Calcium Fluoride (CaF2)

- Wavelength Range: 185-2100nm (Fused Silica), 180-8000nm (CaF2)

- Dimension Tolerance: Fused Silica: +0.0/-0.1mm, CaF2: +0.0/-0.2mm

- Thickness Tolerance: ±0.1mm

- Effective Diameter: >85%

- Flatness: 1′ (Standard), 10″ (High Precision) for Fused Silica; 1′ for CaF2

- Surface Quality: 60-40 (Standard), 20-10 (High Precision) for Fused Silica; 60/40 (Standard) for CaF2

- Wavefront Distortion: λ/10 @ 632.8nm (High Precision) for Fused Silica; λ @ 632.8nm for CaF2

- Chamfer: <0.25mm×45°

- Coating: Customizable

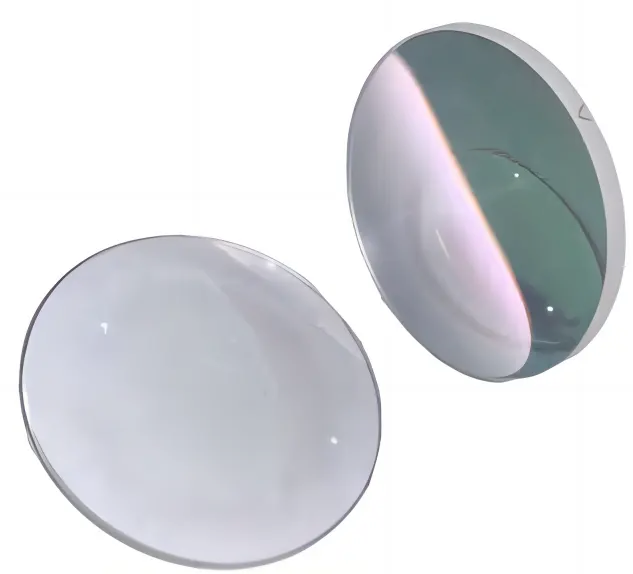

Description

Shape Optics’ parallel windows are manufactured using premium Fused Silica and Calcium Fluoride (CaF2) materials. These windows are designed to offer superior performance across a wide wavelength range, making them suitable for various high-precision optical applications. With precise tolerances and excellent surface quality, these parallel windows ensure minimal optical distortion and high transmission efficiency.

Physical Properties

| Property | Fused Silica | Calcium Fluoride (CaF2) |

|---|---|---|

| Material | Fused Silica | Calcium Fluoride (CaF2) |

| Wavelength Range | 185-2100nm | 180-8000nm |

| Dimension Tolerance | +0.0/-0.1mm | +0.0/-0.2mm |

| Thickness Tolerance | ±0.1mm | ±0.1mm |

| Effective Diameter | >85% | >85% |

| Flatness | 1′ (Standard), 10″ (High Precision) | 1′ |

| Surface Quality | 60-40 (Standard), 20-10 (High Precision) | 60/40 (Standard) |

| Wavefront Distortion | λ/10 @ 632.8nm (High Precision) | λ @ 632.8nm |

| Chamfer | <0.25mm×45° | <0.25mm×45° |

| Coating | Customizable | Customizable |

Optical Properties

Shape Optics’ parallel windows are optimized for high transmission and minimal optical distortion. These windows provide excellent flatness and surface quality, ensuring superior performance in various optical systems. Customizable anti-reflective coatings are available to enhance performance in specific wavelength ranges.

Standard Specifications

- Material: Fused Silica, Calcium Fluoride (CaF2)

- Wavelength Range: 185-2100nm (Fused Silica), 180-8000nm (CaF2)

- Dimension Tolerance: Fused Silica: +0.0/-0.1mm, CaF2: +0.0/-0.2mm

- Thickness Tolerance: ±0.1mm

- Effective Diameter: >85%

- Flatness: 1′ (Standard), 10″ (High Precision) for Fused Silica; 1′ for CaF2

- Surface Quality: 60-40 (Standard), 20-10 (High Precision) for Fused Silica; 60/40 (Standard) for CaF2

- Wavefront Distortion: λ/10 @ 632.8nm (High Precision) for Fused Silica; λ @ 632.8nm for CaF2

- Chamfer: <0.25mm×45°

- Coating: Customizable

Applications

Shape Optics’ parallel windows are ideal for use in high-precision laser systems, spectroscopy, imaging systems, and scientific research. Their high-quality construction ensures reliability and performance in demanding optical environments.

Processing and Handling

Our parallel windows undergo rigorous quality control and precision manufacturing processes. Handling instructions are provided to maintain the optical integrity of the windows during installation and use.

Why Choose Shape Optics

Shape Optics is committed to providing high-precision optical components that meet the highest standards of quality and performance. Our extensive experience and state-of-the-art manufacturing facilities ensure that we can deliver custom solutions tailored to your specific needs.

Shape Optics Strength and Capabilities

- Advanced manufacturing technology

- High precision and quality control

- Customizable solutions to meet diverse optical requirements

- Expertise in a wide range of optical materials and applications

For more information about our parallel windows and other optical components, please contact Shape Optics or visit our website.