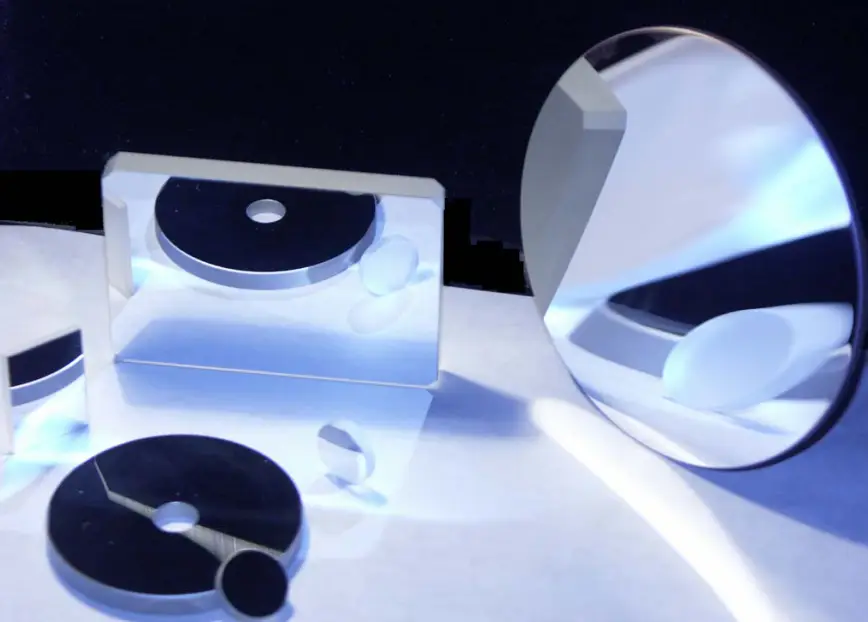

Shape Optics Technologies Pte Ltd (SOT) manufactures premium metallic mirrors using high-quality metal coatings such as aluminum, silver, and gold, delivering stable and efficient reflection over a broad spectral range. These mirrors are fabricated on substrates including K9 optical glass, JGS1 fused silica, and Pyrex, ensuring excellent optical performance and mechanical stability.

Compared with dielectric mirrors, metallic mirrors are less sensitive to angle of incidence and polarization, making them highly adaptable in complex optical systems. With a typical surface flatness of 1/2λ and parallelism better than 3 arcminutes, SOT metallic mirrors ensure consistent, accurate optical performance even under demanding operating conditions.

Their robust coating design allows reliable operation in high temperature, pressure, and harsh environmental environments, making them suitable for industrial, military, and scientific applications.

Key Features

- High Broadband Reflectivity: Metallic mirrors provide excellent reflectivity across UV, VIS, and IR wavelengths, making them ideal for broadband optical systems.

- Exceptional Durability: Robust metallic coatings offer strong adhesion and long-term resistance to environmental stress, humidity, and corrosion.

- High Precision Manufacturing: Produced with tight tolerances, high surface accuracy, and low wavefront error, suitable for precision optical instruments.

- Wide Wavelength Coverage: Effective from 200 nm to 2000 nm, supporting diverse optical and laser applications.

- Versatile Use Cases: Widely used in medical devices, laser range finders, environmental monitoring systems, and high-precision optical instruments.

Spectrum & Customization

If standard products do not meet your needs, SOT provides custom metallic mirror designs, tailored to specific wavelengths, surface quality, sizes, and substrates. Mirrors can be optimized for broadband or specific spectral bands, ensuring seamless integration into specialized optical systems.

Coating Quality & Reliability

All metallic mirrors undergo rigorous testing in accordance with international standards:

- Adhesion Test – Meets MIL-C-675C, no blistering or peeling

- Temperature Cycling – Stable from −62°C to +71°C

- Abrasion Resistance – Compliant with MIL-C-675C & CCC-C-440

- Humidity Resistance – 95–100% RH at 49°C, no defects

- Solvent & Cleaning Resistance – No coating damage after acetone/alcohol exposure

- Salt Spray Test – 100 hours at 5% salinity with no corrosion

Standard Specifications

| Specification | Details |

|---|---|

| Substrate Material | K9, JGS1, Pyrex |

| Size Range | Ø3 mm – Ø200 mm |

| Wavelength Range | 200 – 2000 nm |

| Dimensional Tolerance | ±0.1 mm |

| Surface Quality | 40-20 |

| Flatness | 1/2λ |

| Parallelism | < 3′ |

| Coating Materials | Al, Ag, Au with TiO₂ / SiO₂ protection |

| Other Wavelengths | Available upon request |

Standard Products

| Product Type | Description | Reflectivity | Size |

|---|---|---|---|

| UV-Enhanced Aluminum | Optimized for UV performance | R > 80% @ 200–300 nm | D25.4 × T2 |

| Protected Aluminum | Durable broadband VIS coating | R > 90% @ 400–700 nm | D50.8 × T2 |

| Protected Silver | High reflectivity VIS–IR | R > 95% @ 450 nm – IR | D50.8 × T2 |

| Protected Gold | Excellent IR stability | R > 95% @ 2 μm – FIR | D50.8 × T2 |

Customization options are available upon request.

Typical Applications

- Environmental protection and industrial inspection systems

- Medical and optical diagnostic equipment

- Laser range finders and military optics

- High-precision optical measurement instruments