Shape Optics Technologies (SOT) supplies high-performance beamsplitter plates designed to divide a single incident beam into reflected and transmitted paths with tight control over the transmission/reflection (T/R) ratio. Built on BK7 or fused silica substrates and coated with precision thin films, these plates deliver consistent optical performance for imaging, laser, metrology, and research systems.

SOT beamsplitter plates support single-line and broadband designs, enabling system designers to choose the optimal split ratio and wavelength range while maintaining low absorption and high stability. With λ/4 flatness and 60-40 surface quality, they integrate seamlessly into high-precision optical paths.

Key Features

- High Reflectance & Transmission: Precisely controls the split ratio to deliver stable T/R performance with minimal loss—ideal for demanding optical systems.

- Advanced Coating Technology: Available with S1 single-wavelength or broadband beamsplitter coatings, plus S2 AR coatings to optimize performance across target bands.

- Premium Substrates: Fabricated from BK7 or fused silica for excellent optical clarity, durability, and environmental stability.

- High Surface Accuracy: Flatness λ/4 and surface quality 60-40 minimize wavefront distortion and stray scatter.

- Broad Spectral Coverage: Standard and custom options spanning 450–1200 nm, supporting VIS, NIR, and telecom applications.

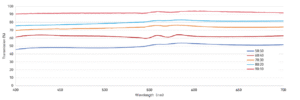

Spectrum Transmission

Standard spectral curves are available for all catalog items. If standard options do not meet your requirements, custom beamsplitter plates can be engineered to your exact wavelength band, T/R ratio, angle of incidence, and substrate.

Standard Specifications

| Model | Incidence angle | Transmission | Wavelength (nm) | Reflectivity | Wavelength (nm) |

|---|---|---|---|---|---|

| 50:50 | 45° | 50%±5% | 400–700 | 50%±5% | 400–700 |

| 60:40 | 45° | 60%±5% | 400–700 | 40%±5% | 400–700 |

| 70:30 | 45° | 70%±5% | 400–700 | 30%±5% | 400–700 |

| 80:20 | 45° | 80%±5% | 400–700 | 20%±5% | 400–700 |

| 90:10 | 45° | 90%±5% | 400–700 | 10%±5% | 400–700 |

Customization options (size, wavelength, T/R ratio, AOI) are available upon request.

Applications

- Optical & Research Systems – Beam splitting and parallel analysis

- Laser Systems – Power monitoring, beam routing, fiber coupling

- Imaging Systems – Split-beam microscopy and multi-path imaging

- Telecommunications – VIS-NIR and 1550 nm systems