Beam Combiners are critical optical components designed to combine or separate laser beams of different wavelengths with high precision. Commonly used in laser system alignment and multi-wavelength laser integration, these optics ensure accurate beam overlap, stability, and system coherence.

SOT beam combiners are fabricated using premium substrates such as ZnSe and BK7/Fused Silica, offering excellent transmission at one wavelength while providing high reflection at another. Their robust optical coatings and high damage thresholds make them ideal for laser cutting, welding, cladding, and medical laser systems, where reliability and performance are essential.

Key Features

- High Damage Threshold – Engineered for demanding, high-power laser applications

- High Transmission – Minimizes optical losses for efficient beam delivery

- Excellent Reflection Performance – Precise wavelength separation and combining

- Multi-Wavelength Compatibility – Suitable for IR and visible laser systems

- Reliable Optical Materials – Available in ZnSe and BK7 / Fused Silica

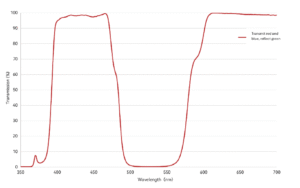

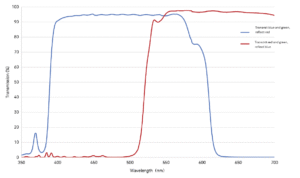

Spectrum Transmission

Standard spectral designs are available for common laser wavelength combinations. When standard configurations do not meet your system requirements, custom beam combiner solutions can be developed based on your exact wavelengths, angles of incidence, and power levels.

Standard Specifications

| Model | Incidence Angle | Transmission | Wavelength (nm) | Reflectivity | Wavelength (nm) |

|---|---|---|---|---|---|

| 1 | 45° | Tave≥95% | 445±10 & 520±10 | R≥98% | 645±10 |

| 2 | 45° | Tave≥95% | 445±10 & 645±10 | R≥98% | 520±10 |

| 3 | 45° | Tave≥95% | 520±10 & 645±10 | R≥98% | 445±10 |

| 4 | 45° | Tave≥95% | 445±10 | R≥98% | 520±10 & 645±10 |

| 5 | 45° | Tave≥95% | 520±10 | R≥98% | 445±10 & 645±10 |

| 6 | 45° | Tave≥95% | 645±10 | R≥98% | 445±10 & 520±10 |

Additional sizes, wavelengths, and coating designs available upon request.

Applications

- Laser Cutting – Multi-wavelength beam integration for precision processing

- Laser Welding – Accurate beam alignment for high-quality joints

- Laser Cladding – Controlled beam combination for surface deposition

- Medical Laser Systems – Precise wavelength management and calibration