Tolerancing is the process of systematically introducing errors—such as manufacturing, assembly, and material variations—into an optical system to evaluate their impact on performance. In Non-Sequential Mode (NSC), tolerancing follows different rules than sequential systems due to the physics-based nature of ray interactions (splitting, scattering, multiple reflections).

This article summarizes key considerations for non-sequential tolerancing, with an example based on a freeform lightpipe illumination system.

Key Points in Non-Sequential Tolerancing

1. Compensators and Constraints

- Compensator min/max bounds are ignored in NSC tolerancing.

- Only the Merit Function and/or User Script define valid criteria.

- To constrain compensator values, use Merit Function boundary operands (e.g., NPGT, NPLT).

2. Use of TOLR in NSC

- TOLR is supported during optimization in Non-Sequential Mode.

- User Script must be the active criterion; selecting the Merit Function as the criterion can create an infinite loop.

- Ensure that Merit Functions loaded by scripts do not themselves contain TOLR operands.

3. Disabled Sequential-Only Settings

Tolerance options that don’t apply to NSC physics—such as ray aiming, separate fields, or separate configurations—are disabled automatically.

4. Multi-Configuration Systems

When tolerancing multi-configuration NSC systems, the Merit Function must explicitly include CONF operands to account for each configuration.

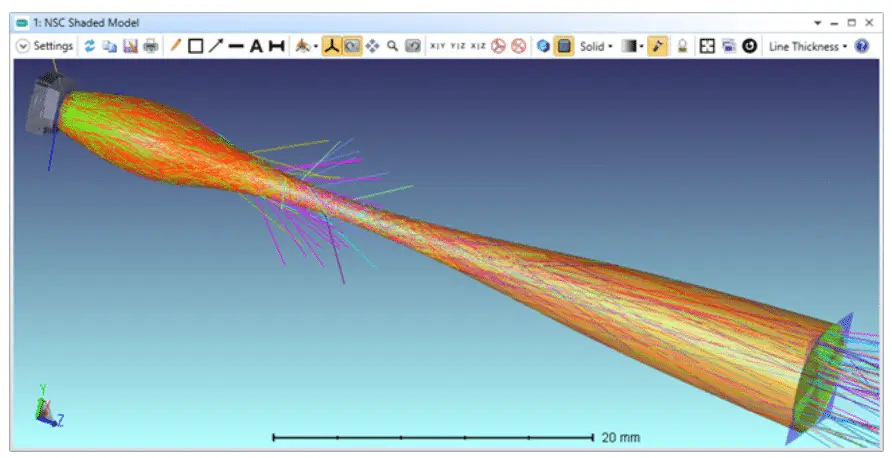

Example: Freeform Lightpipe Tolerancing

As an example, consider an optimized freeform lightpipe system consisting of:

- An OSRAM LED source

- A freeform lightpipe optimized for maximum power transfer and collimation at the detector

The tolerancing study evaluates how realistic errors affect delivered power and beam quality.

Error Categories Considered

Manufacturing Errors

- Incorrect lateral sag at freeform control points

- Incorrect overall thickness

- Incorrect refractive index

Assembly Errors

- LED position and orientation errors

- Detector position and orientation errors

These errors are introduced statistically to assess robustness of the design under production conditions.

Reporting with User Scripts

When a User Script is employed, any desired performance metric can be reported directly in the tolerance output. This is especially useful for:

- Monitoring specific detector metrics (power, uniformity, centroid)

- Tracking custom KPIs not represented by standard operands

- Ensuring production-critical values remain within limits

Practical Guidance

- Prefer User Script–driven criteria for NSC tolerancing to avoid logic conflicts.

- Use boundary operands to enforce practical limits on compensators.

- Ensure the Merit Function explicitly covers all configurations when applicable.

- Start from an over-optimized nominal design to create margin before tolerancing.

Conclusion

Non-sequential tolerancing differs fundamentally from sequential tolerancing. By respecting NSC-specific constraints—especially around compensators, scripts, and configurations—engineers can accurately predict production robustness for complex illumination systems such as freeform lightpipes.

References