Description

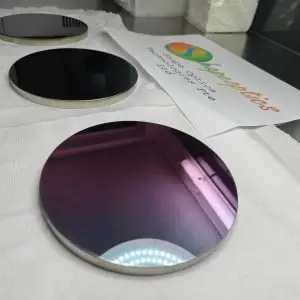

Welcome to our Germanium Milling Piece Customization service, where we specialize in creating high-precision Germanium components tailored to meet the unique needs of your application. Our advanced milling capabilities ensure that each piece is manufactured to the highest standards of quality and accuracy, suitable for a variety of high-tech industries.

Key Products

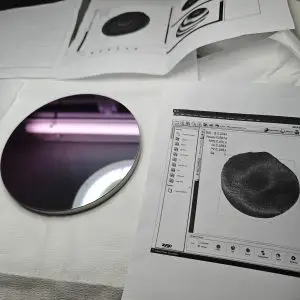

- Optical Components: Custom-milled Germanium lenses, mirrors, and windows for infrared (IR) and laser applications, offering high precision and superior performance.

- Mechanical Components: Germanium parts designed for high-precision mechanical applications in scientific, medical, and industrial equipment.

- Custom Prototypes: Prototyping services for Germanium components, allowing for testing and validation before full-scale production.

Applications

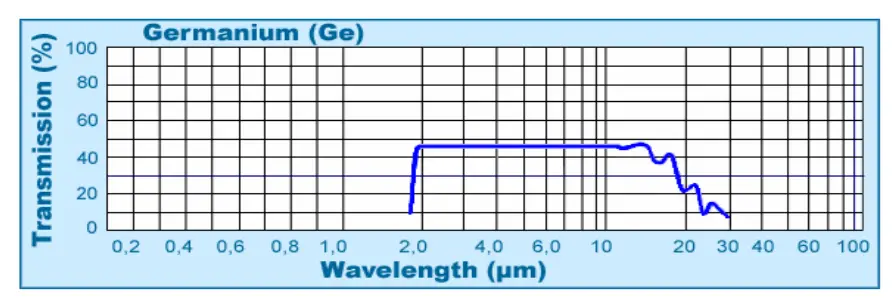

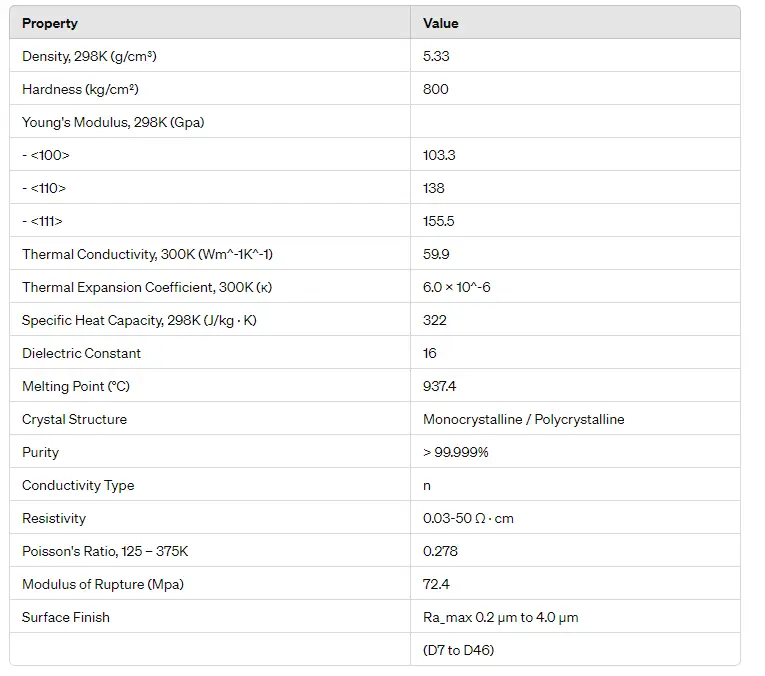

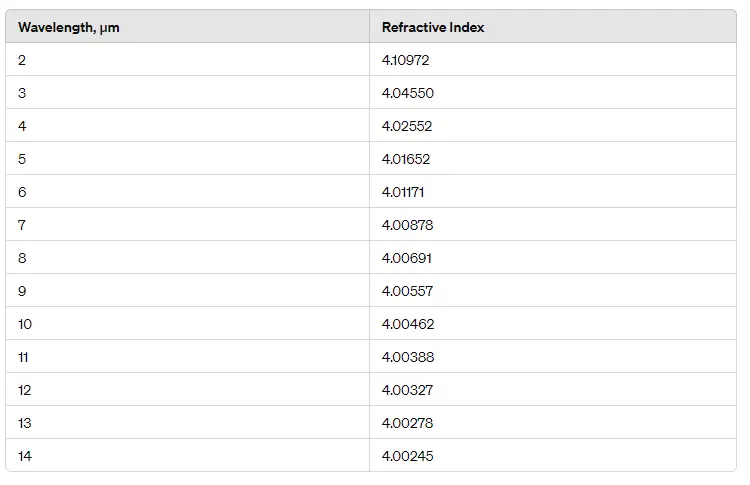

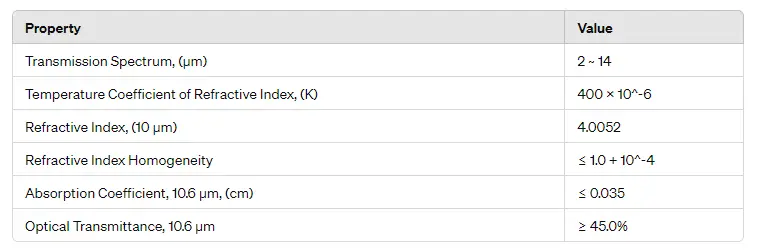

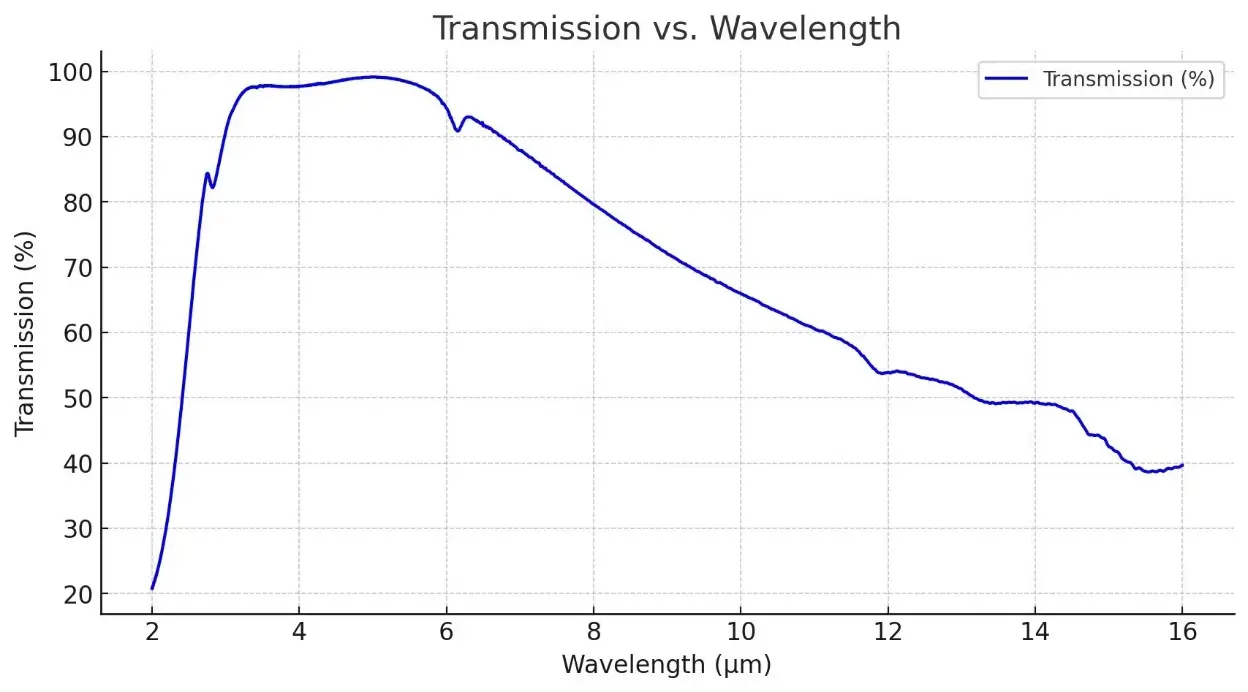

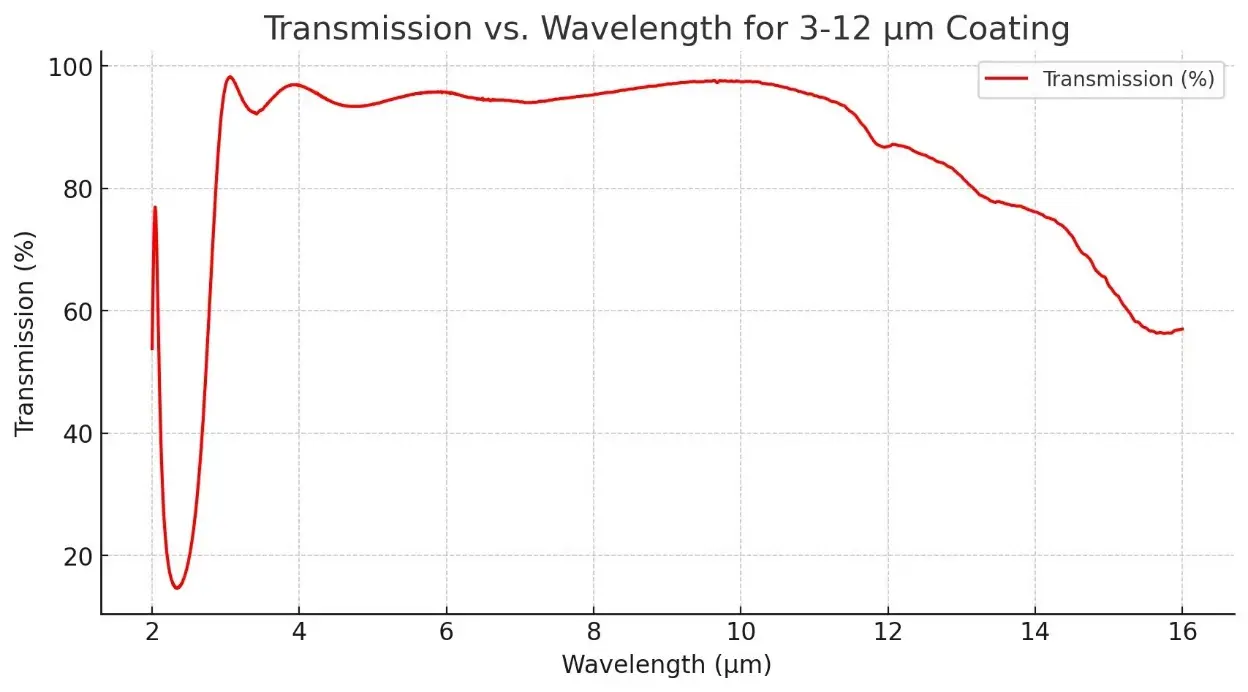

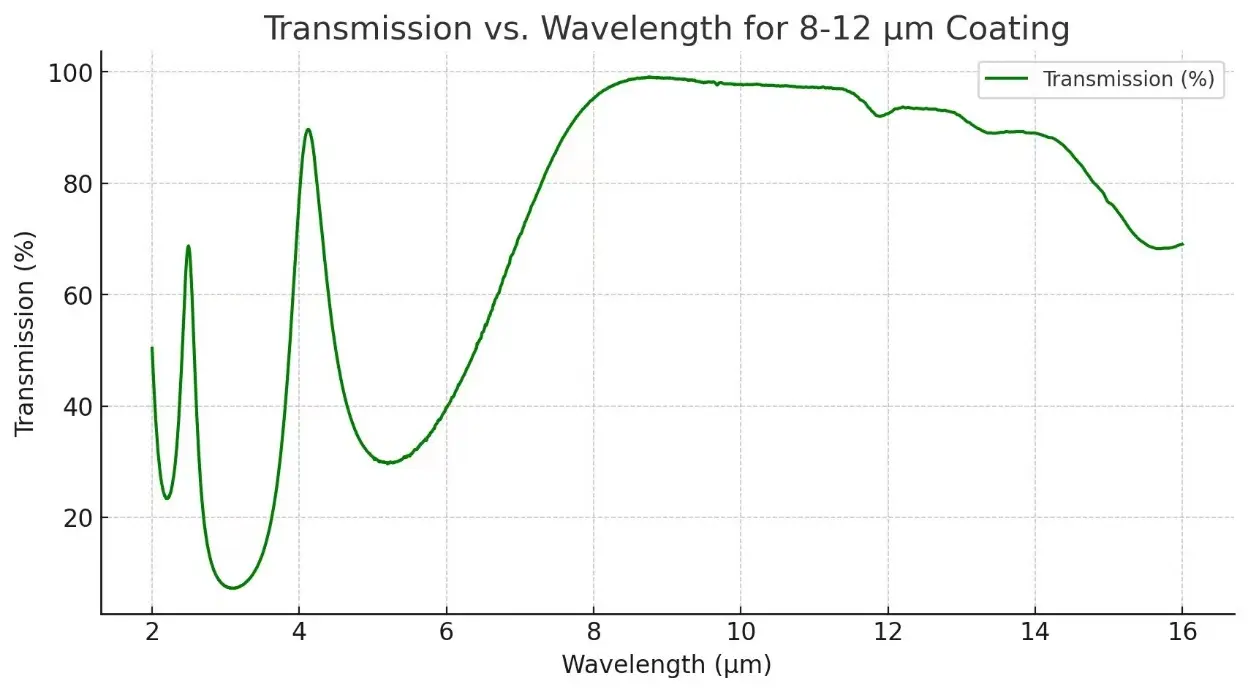

- Infrared Optics: Germanium is ideal for IR optics, including thermal imaging systems, night vision devices, and IR spectroscopy.

- Laser Systems: High-power laser applications benefit from Germanium’s thermal properties and high resistance to thermal shock.

- Medical Devices: Custom-milled Germanium components are used in various medical imaging and diagnostic devices that rely on infrared technology.

- Aerospace and Defense: Germanium milling pieces are used in advanced surveillance, targeting systems, and other critical defense applications.

- Industrial Equipment: Precision Germanium components enhance the performance and reliability of industrial machinery and instruments.

Why Choose Our Germanium Milling Piece Customization Service?

- Expertise: Our team of experienced engineers and technicians specializes in the precise milling of Germanium, ensuring high-quality results for every project.

- Quality Assurance: We implement rigorous quality control measures to ensure that every Germanium piece meets or exceeds industry standards.

- Advanced Technology: Our facility is equipped with the latest milling technology, enabling us to produce highly accurate and consistent components.

- Collaborative Approach: We work closely with our clients to understand their specific needs and provide customized solutions that deliver superior performance.

Ordering Process

- Consultation: Contact us to discuss your specific requirements and project details.

- Design and Prototyping: Our engineers will design your custom Germanium milling pieces using advanced CAD software and create prototypes for evaluation.

- Manufacturing: Once the design is approved, we will manufacture the pieces using our precision milling equipment.

- Quality Inspection: Each piece undergoes thorough quality inspection to ensure it meets your specifications.

- Delivery: We will ship your custom Germanium milling pieces, ensuring they arrive safely and on time.