Description

Items Notes:

- Size, mm: The first lists the dimensions of the crystal in millimeters; W*H*L(mm)

- θ, deg: The second represents the phase-matching angle θ in degrees. This is the angle at which phase matching occurs for nonlinear optical processes.

- φ, deg: The third represents the azimuthal angle φ in degrees. This angle specifies the orientation of the crystal axis in the plane perpendicular to the propagation direction.

- Coating: The fourth describes the coating applied to the crystal, specifying the wavelength range for which the coating is optimized (e.g., P/P @ 400-800 nm).

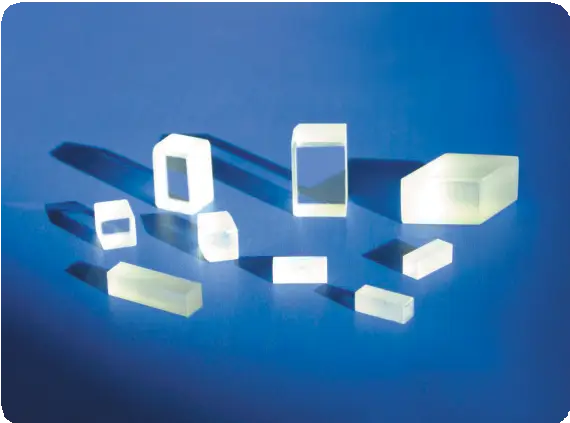

Description: Calcite plates are widely used in optical applications requiring precise control of polarization and phase delay. These plates are designed for Group Velocity Delay (GVD) compensation, allowing for specified ranges of time delay compensation between two different wavelength pulses with orthogonal polarizations. This makes them ideal for advanced optical systems and laser applications.

Physical and Optical Properties:

| Property | Value |

|---|---|

| Material | Natural Calcite |

| Clear Aperture | Ø12 mm |

| Ring Mount Outer Diameter | 25.4 +0.0 / -0.12 mm |

| Surface Quality | 40 – 20 scratch & dig (MIL-PRF-13830B) |

| Wavefront Distortion | λ/4 @ 633 nm |

| Parallelism | < 3 arc min |

| AR Coating | R < 0.5% 760-840 nm and R < 1% at 380-420 nm |

| R < 0.5% at 500-530 +1000-1060 nm |

Features

- Made of calcite crystals

- Designed for different GVD compensation ranges

- Clear aperture Ø12 mm

Specifications

| Specification | Value |

|---|---|

| Material | Natural Calcite |

| Clear Aperture | Ø12 mm |

| Ring Mount Outer Diameter | 25.4 +0.0 / -0.12 mm |

| Surface Quality | 40 – 20 scratch & dig (MIL-PRF-13830B) |

| Wavefront Distortion | λ/4 @ 633 nm |

| Parallelism | < 3 arc min |

| AR Coating | R < 0.5% 760-840 nm and R < 1% at 380-420 nm |

| R < 0.5% at 500-530 +1000-1060 nm |

Detailed Description

Group Velocity Delay (GVD) compensation plates are designed for specified ranges of time delay compensation between two different wavelength pulses with orthogonal polarizations. A compensation plate can be adjusted for the precisely desired delay by angular tuning – changing the angle of incidence (AOI) of the laser beams to the plate. The recommended AOI tuning range of the plate is from -10° to +10°.

Standard GVD compensation plates are rectangular (full aperture 16 x 14 mm) with a clear aperture of Ø12 mm. They are supplied mounted into Ø25.4 mm (1″) ring holders. Calcite plates with clear apertures up to Ø20 mm can be produced on special requests.

The optical axis of calcite plates is at the particular orientation, which is not parallel to the faces of the plate. Thus walk-off effect for e-polarized beam and displacement of both beams at non-zero AOI should be considered in the actual application conditions. The plane of the optical axis is parallel to the long 16 mm edge of the calcite plate and is marked on the ring holder.

Time delay compensators for custom wavelengths, specific delay values, as well as plates made of Alpha-BBO crystals are available on request.

Applications:

- Polarization Control: Ideal for precise polarization control in advanced optical systems.

- Laser Systems: Used in laser systems for GVD compensation and phase delay applications.

- Spectroscopy: Suitable for spectroscopic applications requiring precise control of light polarization and phase delay.

- Scientific Research: Employed in various research settings for optical experiments and innovations.

Processing and Handling:

- Surface Protection: To maintain the integrity of calcite plates, a protective coating may be applied during handling and processing.

- Machining: Requires careful handling to avoid damage to the crystal structure during milling or other machining processes.

Why Choose Shape Optics?

At Shape Optics, we pride ourselves on our comprehensive expertise and advanced capabilities in the field of optical materials and components. Our commitment to quality and innovation has positioned us as a leader in the industry, serving a diverse range of applications from scientific research to industrial manufacturing.

- Advanced Manufacturing: Shape Optics utilizes state-of-the-art equipment and techniques to ensure the highest precision and quality in our products. Our manufacturing processes are designed to meet the stringent demands of modern optical applications.

- Customization: We understand that every project is unique. Shape Optics offers customized solutions tailored to meet the specific needs of our clients. Whether you require specific dimensions, coatings, or performance characteristics, we have the flexibility to deliver.

- Quality Assurance: Our rigorous quality control processes ensure that every product we deliver meets the highest standards of performance and reliability. Shape Optics is committed to continuous improvement and excellence in all aspects of our operations.

- Expertise and Support: With a team of highly skilled professionals, Shape Optics provides unparalleled technical support and expertise. Our team is dedicated to helping you achieve optimal results in your optical applications.

- Global Reach: Shape Optics serves clients worldwide, providing reliable and timely delivery of products. Our global network ensures that we can meet your needs wherever you are located.

- Sustainability and Responsibility: Shape Optics is committed to sustainable practices and responsible manufacturing. We strive to minimize our environmental impact while delivering high-quality optical solutions.

Calcite plates from Shape Optics represent the pinnacle of quality and performance in optical materials. With our advanced capabilities, commitment to quality, and customer-centric approach, Shape Optics is your ideal partner for all your optical needs. Explore the possibilities with our calcite plates and experience the Shape Optics difference.

For more information, please visit our website at Shape Optics or contact us directly to discuss your specific requirements.

Reviews

There are no reviews yet.