Understanding laser safety classifications is essential for minimizing risk and ensuring safe operation of LiDAR systems. Laser safety standards help engineers, operators, and regulators assess the potential hazards associated with laser exposure and implement appropriate control measures. This is particularly important for LiDAR, which often operates at higher optical power levels than consumer laser devices.

Evolution of Laser Safety Classifications

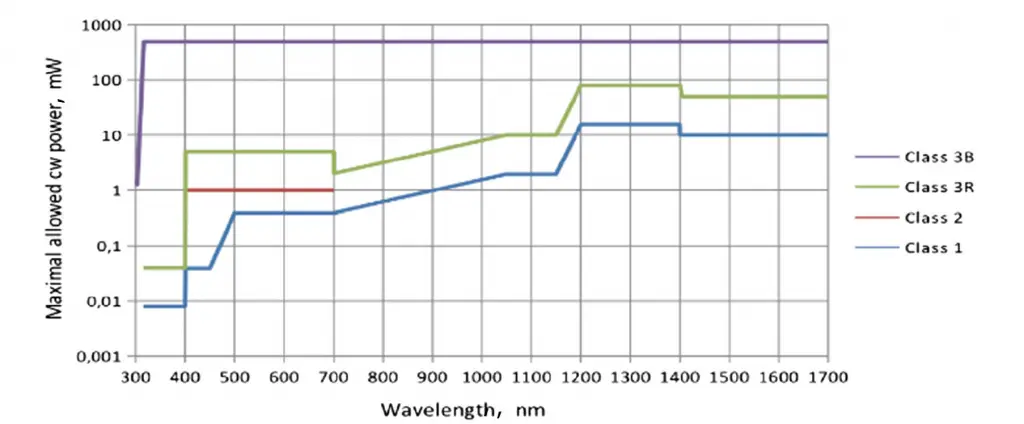

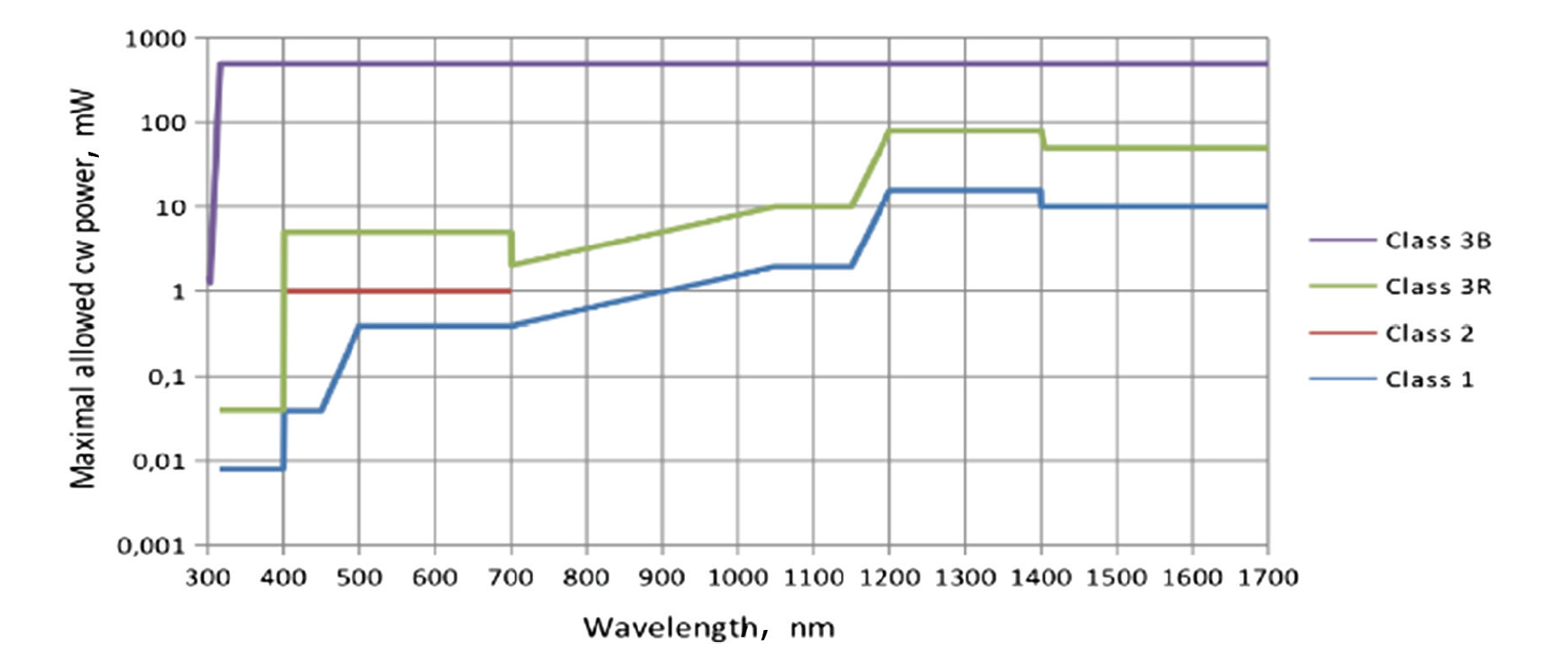

Since the early 1970s, lasers have been categorized into four primary safety classes, with additional subclasses, based on wavelength, output power, and exposure characteristics. These classifications estimate the likelihood of laser radiation causing injury to the eyes or skin.

In 2002, the laser safety classification system was revised to reflect improved understanding of laser–tissue interactions and more realistic exposure scenarios. As a result, many lasers were reclassified into lower-risk categories than under earlier standards, without compromising safety.

Laser Safety Classes Overview

- Class 1 lasers are considered inherently safe under normal operating conditions. Exposure does not exceed safety limits, provided the beam is not intentionally focused. Many enclosed or fiber-based LiDAR systems fall into this category from a user-access perspective.

- Class 2 lasers operate in the visible spectrum (400–700 nm) and are limited to 1 mW continuous-wave (CW) output. Eye safety is ensured by the natural blink reflex, which limits exposure duration to less than 0.25 seconds.

- Class 3R lasers emit up to 5 mW CW. While generally safe when handled responsibly, direct eye exposure should be avoided. Many alignment lasers and low-power laser pointers fall into this category.

- Class 3B lasers can emit up to 30 mW CW (or higher pulsed equivalents). Direct eye exposure is hazardous, and safety measures such as laser safety eyewear, controlled access, and warning labels are required.

- Class 4 lasers represent the highest hazard level. They can cause severe eye and skin injury, burn materials, and pose fire risks. These systems require strict engineering controls, interlocks, protective eyewear, and formal safety procedures.

Laser Safety Concerns in LiDAR Applications

Many consumer laser pointers sold online exceed the 5 mW safety limit, posing unexpected hazards. In LiDAR systems, optical power levels are often significantly higher, making safety classification alone insufficient to fully assess risk.

For LiDAR, the most critical safety metric is the Maximum Permissible Exposure (MPE).

Maximum Permissible Exposure (MPE)

MPE defines the maximum laser energy or power density that the human eye or skin can safely tolerate without injury. It is typically expressed in J/cm² or W/cm² and depends on:

- Wavelength

- Exposure duration

- Beam diameter and divergence

- Pulse repetition rate (for pulsed systems)

Unlike laser class labels, which provide a general hazard category, MPE values represent the definitive safety threshold, especially for LiDAR systems where beam scanning, dwell time, and exposure geometry vary continuously.

Why MPE Matters More Than Laser Class in LiDAR

- LiDAR beams are often scanned, reducing exposure time per location

- Eye exposure depends on distance, aperture size, and dwell time

- High-peak-power pulsed lasers can still be eye-safe if MPE limits are respected

As a result, many LiDAR systems classified as Class 3B or Class 4 at the source can still be designed to be eye-safe at the aperture or beyond a specified distance, provided MPE requirements are met.

Summary

Laser safety classifications provide a valuable first-level assessment of laser hazards, but they do not tell the full story for LiDAR systems. In practice, Maximum Permissible Exposure (MPE) is the governing safety criterion, especially for systems operating at high power, high repetition rates, or over extended periods.

Proper understanding and application of laser safety classes and MPE limits allow LiDAR designers and operators to achieve high-performance sensing while ensuring human eye and skin safety in real-world environments.