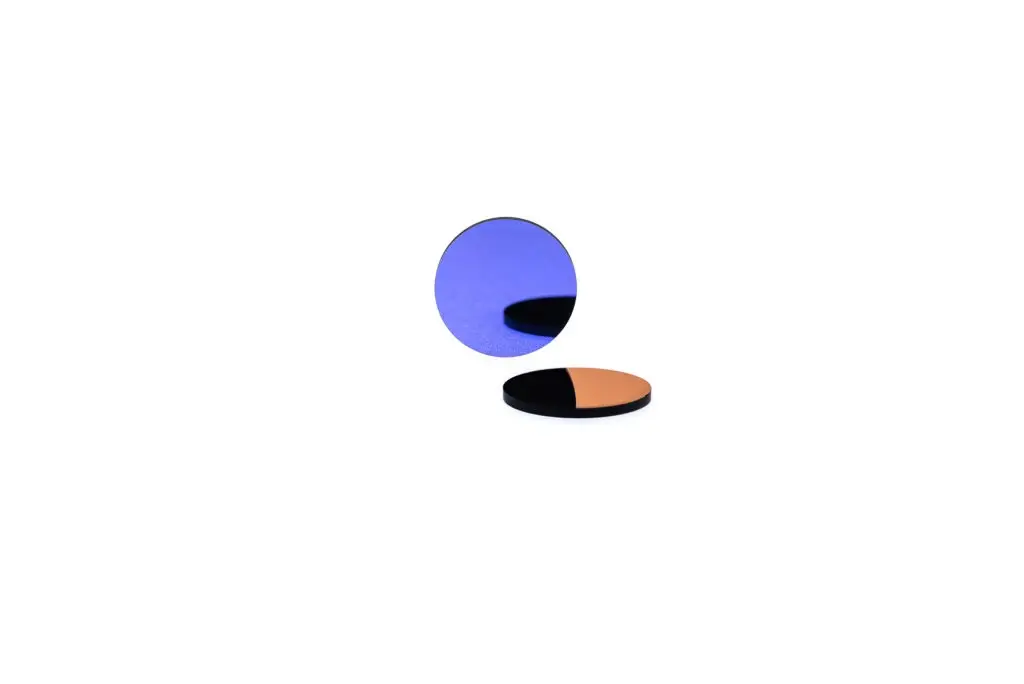

Laser Radar Mirrors are high-performance dielectric mirrors engineered for LiDAR and laser radar systems. These mirrors are designed to efficiently reflect laser wavelengths commonly used in ranging applications—850 nm, 905 nm, 940 nm, and 1550 nm—while maintaining exceptional durability and optical stability.

In LiDAR architectures, mirrors play a critical role in beam steering, scanning, and signal routing. SOT’s laser radar mirrors leverage advanced multilayer dielectric coatings to deliver near-lossless reflection, supporting accurate time-of-flight measurements and reliable signal detection over long distances.

Whether deployed in autonomous vehicles, environmental monitoring platforms, industrial automation, or aerospace systems, SOT’s mirrors provide the precision and robustness required for continuous operation in demanding conditions. Custom designs are available to integrate seamlessly with both existing and next-generation LiDAR systems.

Key Features

- Precision Performance for LiDAR – Optimized to maximize return signal strength and minimize optical losses in laser radar systems

- Ultra-High Reflectivity – Rave ≥ 99% at key LiDAR wavelengths (850 nm, 905 nm, 940 nm, 1550 nm)

- Advanced Hard Coatings – High damage resistance, scratch resistance, and long-term environmental stability

- Customizable Optical Design – Tailored wavelength bands, AOI, coating stacks, substrates, and sizes

- Reliable in Harsh Environments – Designed to maintain performance under temperature cycling, humidity, abrasion, and salt exposure

- Accurate Detection & Mapping – Enables precise distance measurement and high-fidelity 3D point clouds

Spectral Performance

Each mirror is optimized for its designated wavelength band with flat, high reflectivity across the operating range.

Custom spectral designs and AOI optimization are available to match your optical layout and laser source.

Coating Parameters

| Parameter | Value |

|---|---|

| Transmittance | T ≥ 99% (Customization available upon request) |

| Transmission Wavelength (CWL) | 850 ± 15 nm, 905 ± 15 nm, 1535 ± 15 nm, 1550 ± 15 nm (selection based on customer’s requirements) |

| Incidence Angle | Convention 0° (customizable) |

| Note | Conductive films can be coated, and the sheet resistance requirements can be customized. |

Common LiDAR Reflective Mirrors

| Model | Reflection Range (nm) | Reflectivity | Model | Reflection Range (nm) | Reflectivity |

|---|---|---|---|---|---|

| 850nm | 800–900 | Rave ≥ 99% | 940nm | 900–980 | Rave ≥ 99% |

| 905nm | 890–920 | Rave ≥ 99% | 1550nm | 1500–1600 | Rave ≥ 99% |

Applications

- Autonomous Vehicles & ADAS – Beam steering and signal routing in automotive LiDAR

- Environmental Monitoring – Forest density, air quality, and terrain analysis

- Geophysical Surveying – Topographical mapping and geological exploration

- Industrial Automation – Laser scanning, inspection, and material handling

- Defense & Security – Surveillance, target tracking, and reconnaissance systems

- Aerospace – Altitude measurement, terrain mapping, and navigation LiDAR

Looking for a custom LiDAR reflective mirror?

Share your wavelength, AOI, size, substrate, and environmental requirements—we’ll tailor the optimal LiDAR mirror for your system.