Infrared (IR) optical filters are essential components used to control, isolate, or modify infrared radiation in optical systems. By selectively transmitting specific wavelength regions and blocking others, IR filters improve measurement accuracy, imaging contrast, and system stability.

These filters are widely integrated into thermal imaging cameras, infrared sensors, spectroscopy systems, environmental monitoring instruments, and industrial inspection equipment. Advanced thin-film coating technologies ensure stable spectral performance, long-term durability, and resistance to harsh operating environments, including temperature cycling, humidity, and chemical exposure.

Custom designs are available to meet different center wavelengths (CWL), bandwidths (FWHM), substrates, and environmental requirements, making IR filters adaptable to a broad range of applications.

Key Features

- Selective Infrared Transmission: Designed to transmit defined infrared wavelength bands while blocking unwanted radiation.

- High Optical Transmission: Excellent in-band transmission ensures strong signal throughput and system efficiency.

- Sharp Spectral Edges: Steep cut-on and cut-off slopes reduce spectral overlap and improve measurement accuracy.

- High Contrast Performance: Enhances signal-to-noise ratio in infrared imaging and sensing systems.

- Wide Spectral Coverage: Suitable for MWIR and LWIR applications across scientific, industrial, and security systems.

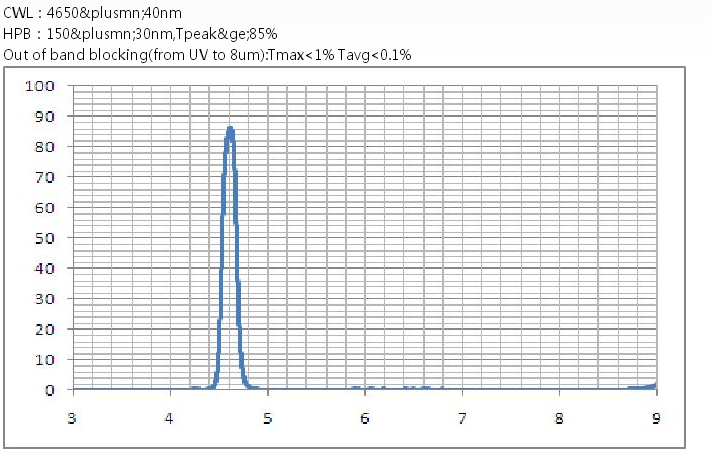

Spectrum Transmission Curves

Infrared filter performance is defined by transmission-versus-wavelength curves, which illustrate:

- High transmission within the designed infrared band

- Controlled bandwidth (FWHM) for spectral selectivity

- Deep out-of-band blocking to suppress unwanted radiation

Custom wavelength ranges can be manufactured to match specific system requirements.

Example IR Wavelength Regions:

3420-3970nm

3400-4000nm

3520-4030nm

4650nm

5360nm

8200nm

8800nm

9360nm

Coating Quality & Reliability Testing

All infrared filters supplied by SOT undergo comprehensive testing to ensure long-term reliability:

- Adhesion Test: Qualified to MIL-C-675C, with no blistering or peeling.

- Temperature Cycling: −62 °C to +71 °C per MIL-C-675C, no coating failure.

- Abrasion Resistance: Tested per MIL-C-675C / CCC-C-440, no damage after repeated abrasion.

- Humidity Resistance: 95–100% RH at 49 °C for 24 hours, no degradation.

- Solvent Resistance: Stable after acetone and alcohol cleaning.

- Salt Spray Test: 100 hours in 5% saline environment, no coating deterioration.

Standard Specifications (Typical)

| Parameter | Specification |

|---|---|

| Center Wavelength (CWL) | Customizable |

| Peak Transmission | >85% |

| Blocking | OD3 or higher |

| Thickness | 6 mm (mounted) |

| Substrate Materials | JGS1, K9, Quartz (others on request) |

| Spectral Range | 3.4 µm – 16.0 µm |

| Bandwidth (FWHM) | 180–300 nm |

Applications of Infrared Filters

- Thermal Imaging & Thermography: Improves contrast and measurement accuracy in industrial, medical, and defense thermal systems.

- Infrared Sensing & Detection: Used in temperature sensing, motion detection, and IR measurement instruments.

- Environmental & Industrial Monitoring: Supports infrared analysis and monitoring systems operating in harsh environments.

- Security & Surveillance Systems: Enhances infrared imaging performance for surveillance and inspection.

- Aerospace & Avionics: Integrated into IR detection and sensing systems for airborne and space applications.

- Scientific & Research Instruments: Used in spectroscopy, material analysis, and laboratory IR systems.

SOT Strengths & Capabilities

Shape Optics Technologies specializes in the design and manufacture of high-quality infrared optical filters, supporting a wide range of industrial, scientific, and commercial IR systems.