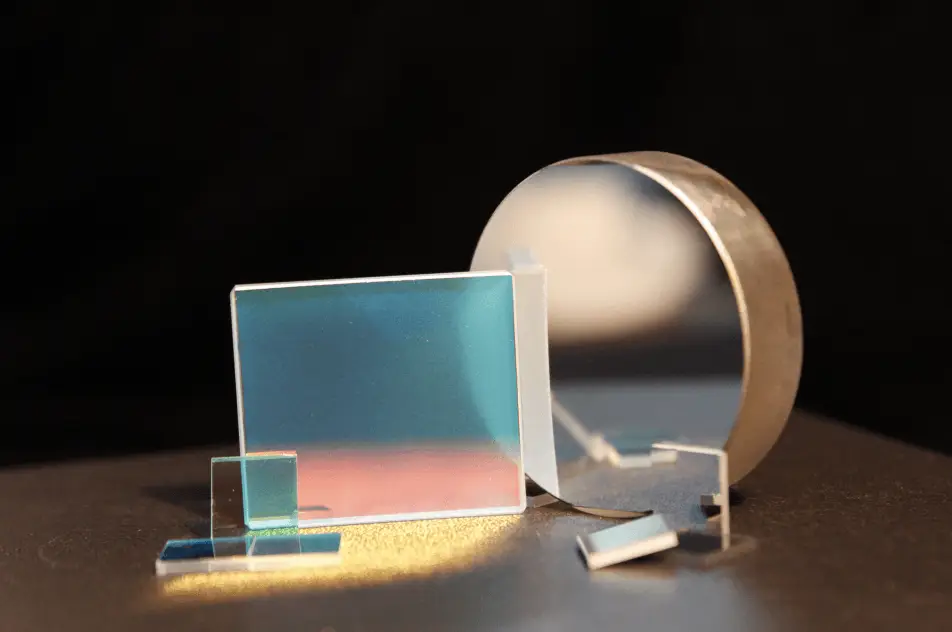

Shape Optics Technologies Pte Ltd (SOT) offers high-performance Dielectric High-Reflection (HR) Mirrors designed for applications requiring maximum reflectivity, thermal stability, and long service life. These mirrors utilize advanced dielectric multilayer coatings deposited on high-quality substrates such as JGS1 fused silica and K9 optical glass.

Compared with metallic mirrors, dielectric HR mirrors provide higher reflectivity, lower absorption, and significantly higher laser damage thresholds, making them ideal for high-power laser systems and precision optical instruments. SOT dielectric HR mirrors are available in various sizes and angles of incidence (AOI), typically 0° and 45°, enabling seamless integration into complex optical assemblies.

Key Features

- Ultra-High Reflectivity: Dielectric HR mirrors deliver exceptional reflectivity, typically >99%, with selected designs reaching >99.99%, ensuring minimal optical loss.

- High Damage Threshold: Engineered for high-power and high-energy laser systems, suitable for demanding industrial and scientific environments.

- Excellent Durability: Multilayer dielectric coatings provide superior adhesion, abrasion resistance, and long-term environmental stability.

- Wide Wavelength Coverage: Available for UV, Visible, and IR wavelengths, spanning 200 nm to 2000 nm.

- Easy Maintenance: Chemically stable coatings allow safe cleaning and reliable operation in harsh conditions.

Spectrum & Custom Designs

Standard wavelength designs are available as listed below.

If off-the-shelf products do not meet your requirements, custom dielectric HR mirrors can be designed for specific wavelengths, bandwidths, AOI, and reflectivity targets.

Coating Quality & Reliability

All dielectric HR mirror coatings comply with stringent international standards:

- Adhesion Test – Meets MIL-C-675C, no blistering or peeling after repeated tape tests

- Temperature Cycling – Stable from −62°C to +71°C, no coating detachment

- Abrasion Resistance – Meets MIL-C-675C & CCC-C-440, no surface damage

- Humidity Resistance – 95–100% RH at 49°C for 24 hours, coating remains intact

- Solvent & Cleaning Resistance – No peeling after acetone and alcohol exposure

- Salt Spray Test – 100 hours at 5% salinity with no corrosion or coating failure

Standard Specifications

| Wavelength (nm) | Reflectivity | Size (mm) | Material | Product Code (0°) | Product Code (45°) |

|---|---|---|---|---|---|

| 248 | R > 99% | D25.4 | JGS1 | DM-B-248-J02 | DM-A-248-J02 |

| 355 | R > 99% | D25.4 | JGS1 | DM-B-355-J02 | DM-A-355-J02 |

| 365 | R > 99% | D25.4 | JGS1 | DM-B-365-J02 | DM-A-365-J02 |

| 442 | R > 99.8% | D25.4 | K9 | DM-B-442-K02 | DM-A-442-K02 |

| 808 | R > 99.8% | D25.4 | K9 | DM-B-808-K02 | DM-A-808-K02 |

| 1550 | R > 99.8% | D25.4 | K9 | DM-B-1550-K02 | DM-A-1550-K02 |

| 300–550 | R > 99% | D25.4 | JGS1 | DM-C-300-550-J02 | — |

| 400–700 | R > 99% | D25.4 | K9 | DM-C-400-700-K02 | — |

| 900–1100 | R > 99% | D25.4 | K9 | DM-C-900-1100-K02 | — |

Typical Applications

- Stage-engineering laser high-reflection mirrors

- High-power laser reflection and beam steering systems

- Precision optical instruments and laboratory equipment

- Digital microscopes and imaging systems

- Galvanometer laser motors

- Laser barcode scanners and projector optical engines