Sequential tolerance analysis evaluates how manufacturing defects and alignment errors affect optical system performance. It answers a critical production question: Will the as-built system still meet specifications?

This article introduces the fundamentals of sequential tolerancing using a laser beam expander intended for volume production.

Design Objective and Nominal Performance

Assume the task is to design a 3× laser beam expander for an argon-ion laser with the following requirements:

-

Input beam size: 2.5 mm (1/e² full width)

-

Expansion ratio: 3×

-

Output beam diameter: 7.5 mm (1/e²)

-

Wavefront error requirement:

-

≤ 1/20 waves RMS

-

Evaluated over two full beam widths (total diameter = 5 mm)

-

The nominal (ideal) design significantly exceeds this specification, providing adequate margin before tolerancing is applied. This is an essential starting point for any tolerance analysis.

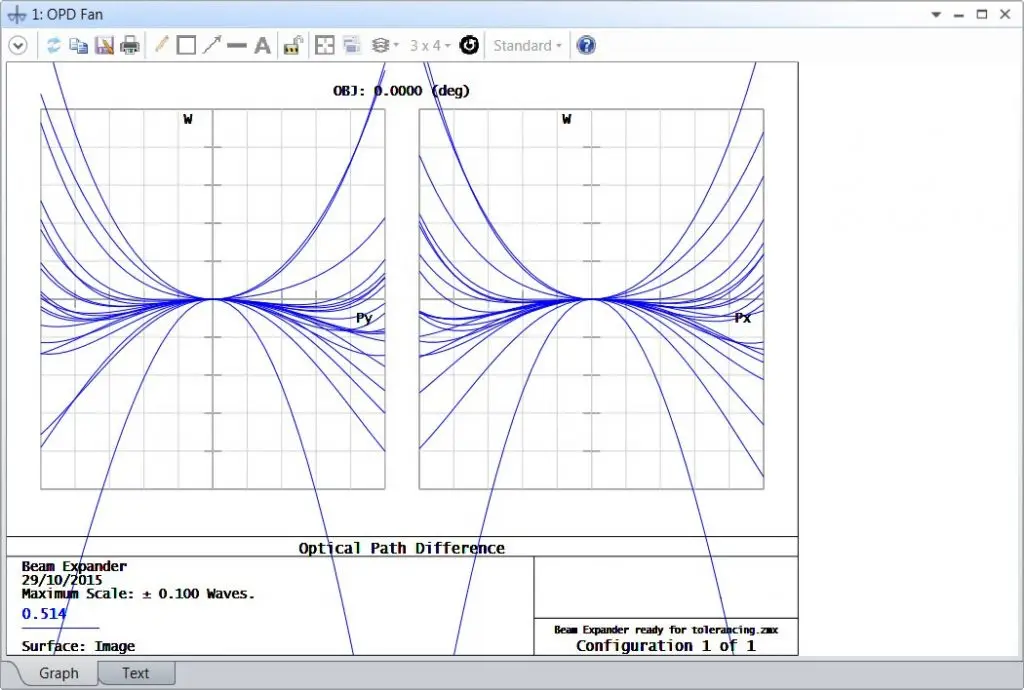

The nominal system performance greatly exceeds that is required in production, as shown in figure below:

Why Manufacturing Tolerances Matter

Tolerancing accounts for the reality that no optical system is built exactly as designed. Common sources of error include:

- Radius and thickness variations

- Surface irregularity

- Element decenter and tilt

- Refractive index variation

- Assembly and alignment errors

The goal is to ensure that the as-built performance, not just the nominal design, satisfies the specification.

The Tolerancing Setup

The Set-Up tab in the tolerancing dialog defines how tolerance data is generated and evaluated. It is commonly used in conjunction with Monte Carlo analysis, which statistically simulates the combined effects of all tolerances.

Before beginning:

- Open the tolerancing dialog

- Press Reset to restore default settings

- Confirm that the evaluation criteria (e.g., RMS wavefront error) are correctly defined

First Monte Carlo Tolerancing Run

In the first tolerancing run:

- Monte Carlo graphics are enabled

- An OPD (Optical Path Difference) plot is open

- 20 Monte Carlo trials are generated

The overlaid OPD plots show the distribution of wavefront error across all trials.

Result

The system performance is far from the target of 0.05 waves RMS (1/20). This indicates that, although the nominal design is excellent, it is not yet robust enough for production when realistic tolerances are applied.

Iterative Nature of Tolerancing

Tolerance analysis is not a one-pass process. It typically requires multiple iterations:

- Over-optimize the nominal design to create margin

- Identify the dominant error contributors

- Tighten critical tolerances or relax non-critical ones

- Re-optimize with tolerances applied

- Re-run Monte Carlo analysis

In general, the nominal design should comfortably exceed the target specification before tolerancing is considered complete.

Key Takeaway

Sequential tolerance analysis bridges the gap between optical design and manufacturability. A design that performs exceptionally well in theory may fail in production unless tolerances are properly understood, allocated, and mitigated through iterative optimization.

References