Key Features

- Hardest of the oxide crystals: Sapphire boasts exceptional hardness, surpassed only by diamond.

- Excellent transparency and thermal properties: Offers high transparency from UV to IR wavelengths and exceptional thermal stability.

- Chemically inert and insoluble: Resistant to chemical reactions and almost insoluble in water and acids.

- Superior abrasion and scratch resistance: Eight times higher abrasion stability compared to standard glass.

Description

Sapphire (Al₂O₃) is an anisotropic monocrystal that is renowned for its exceptional hardness, chemical inertness, low friction coefficient, and outstanding optical and electrical properties. Its unique attributes make it ideal for applications requiring material stability under extreme conditions, such as high temperature, high pressure, and chemically aggressive or abrasive environments.

Function

Sapphire is widely used as a material for manufacturing optical windows, lenses, and other components that need to maintain high performance under demanding conditions. Its excellent transmission range, from UV to near-infrared, makes it suitable for various optical applications, including high-precision instrumentation and aerospace optics.

Physical Properties

- Chemical Formula: Al₂O₃

- Crystal Class: Hexagonal system, rhombohedral class 3 m

- Lattice Constants: a = 4.758, c = 12.991

- Density: 3.97 g/cm³

- Hardness: 2200 HV (Knoop)

- Surface Quality: 60/40

- Refractive Index (at 0.532 µm): nₒ = 1.768, nₑ = 1.760

- Young’s Modulus: 345 GPa

- Shear Modulus: 145 GPa

- Melting Point: 2040°C

Optical Properties

- Transmission Range: 0.17 – 5.5 µm

- Refractive Index:

- At 0.3 µm: n = 1.814

- At 5 µm: n = 1.623

- Optical Transmission Range: 0.175 – 5 µm

- Birefringence: 0.008 (difference in the refractive index in orthogonal directions)

Standard Specifications

- Diameter Tolerance: ±0.13 mm

- Thickness Tolerance: ±0.2 mm

- Surface Flatness: 1 per inch at 633 nm

- Clear Aperture: 80% of the diameter

- Parallelism: 3 arcmin

- Orientation: C-cut

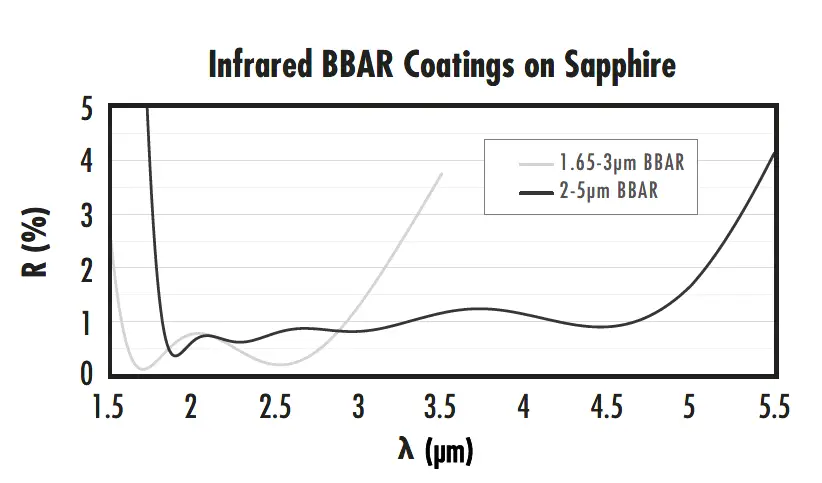

- Coatings: Available with BBAR coating @ 1-5 µm, Diamond-Like Carbon (DLC) coating @ 1-5 µm

Other Properties

- Water Absorption: Nil

- Bending Modulus: 240 MPa at 200°C

Applications

- Optical Windows: Used in harsh environments requiring UV to IR transmission.

- Aerospace Optics: Ideal for high-pressure and high-temperature conditions.

- Precision Instrumentation: Suitable for high-precision and durable optical components.

- Medical Devices: Utilized in biomedical optics due to its chemical inertness and biocompatibility.

Processing and Handling

Sapphire requires precision machining due to its hardness. Handling should be performed with care to avoid surface damage. Specialized equipment is recommended for cutting, polishing, and coating processes to achieve the desired optical and physical properties.

Why Choose Shape Optics

Shape Optics provides high-quality sapphire components that are meticulously manufactured to meet stringent specifications. Our advanced production techniques and quality control ensure that each product delivers optimal performance and durability.

Shape Optics Strength and Capabilities

- Advanced Manufacturing: Utilizes state-of-the-art technology for precision cutting and polishing.

- Quality Assurance: Rigorous quality control processes to ensure consistency and performance.

- Customization: Capabilities to produce custom sizes and specifications to meet unique application needs.

- Expertise: Decades of experience in the optics industry, providing innovative solutions and support to our clients.