Additional information

| Weight | 0.5 kg |

|---|---|

| Dimensions | 12 × 10 × 8 cm |

$797.00

Important Remark

The minimum cart order value is USD 2,000. Stock and lead time are subject to confirmation, and listed prices are for reference only—please email us to confirm availability and final pricing before ordering.

| Weight | 0.5 kg |

|---|---|

| Dimensions | 12 × 10 × 8 cm |

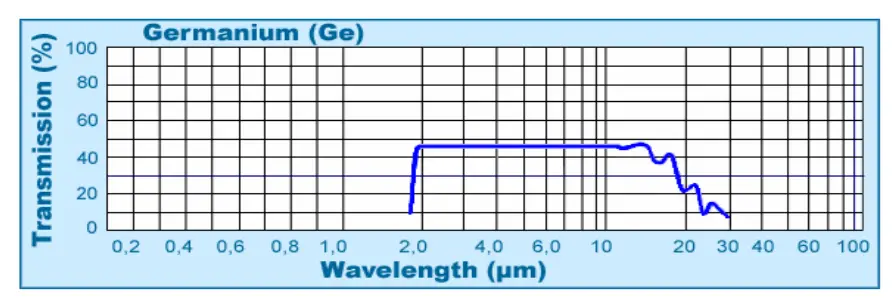

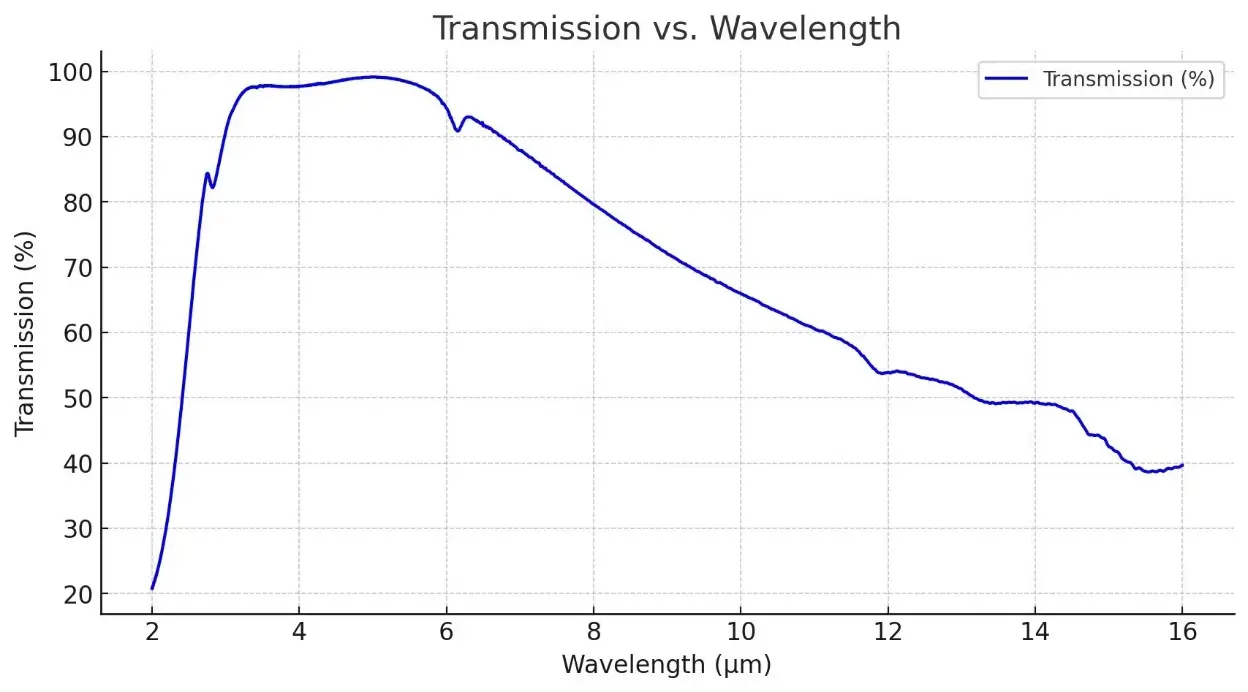

This graph provides a visual representation of how the transmission behaves across the specified wavelength range for a 1mm thick Germanium (monocrystalline) window. There is a sharp increase to 50% transmission starting from 2 µm and remains constant through 16 µm.

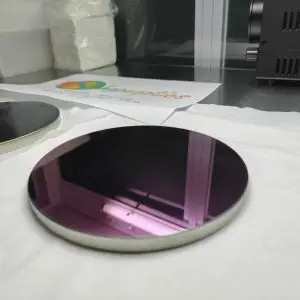

Shape Optics Diamond-Like Carbon (DLC) Coated Germanium Windows are engineered for exceptional durability, environmental resistance, and long-term infrared performance in demanding applications. Each window features a high-efficiency broadband anti-reflection (AR) coating on one surface to maximize infrared transmission, while the opposite surface is protected with a hard, abrasion-resistant DLC coating. This dual-coating configuration delivers excellent optical throughput while providing superior protection against mechanical wear and harsh environmental exposure. The DLC-coated surface is designed to withstand extreme temperature cycling from −80°F to +160°F, 24 hours of continuous salt spray, 24-hour salt immersion, and up to 5,000 wiper oscillations using a sand-and-slurry mixture. In addition, these windows meet the severe abrasion resistance requirements of MIL-C-675C, making them well suited for thermal imaging, FLIR systems, airborne sensors, and other infrared applications operating in rugged environments.

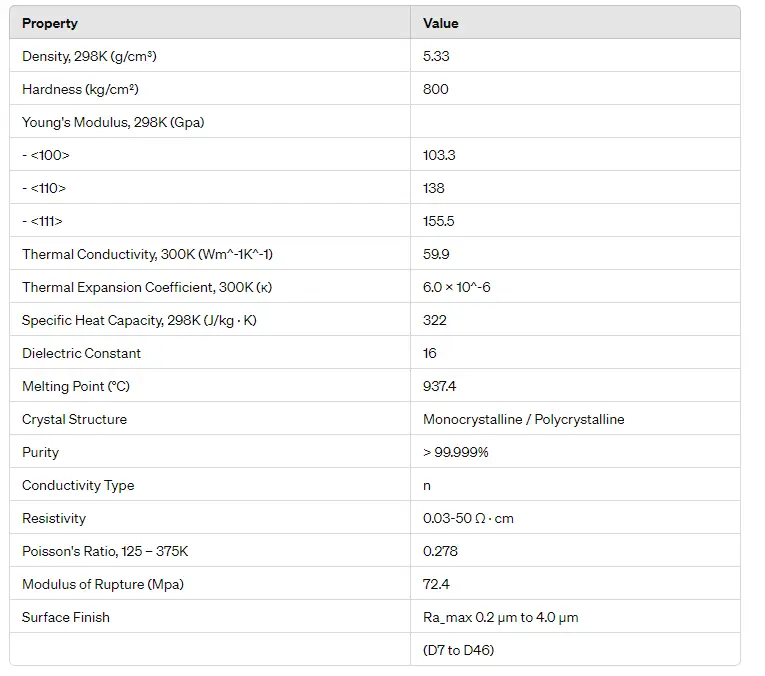

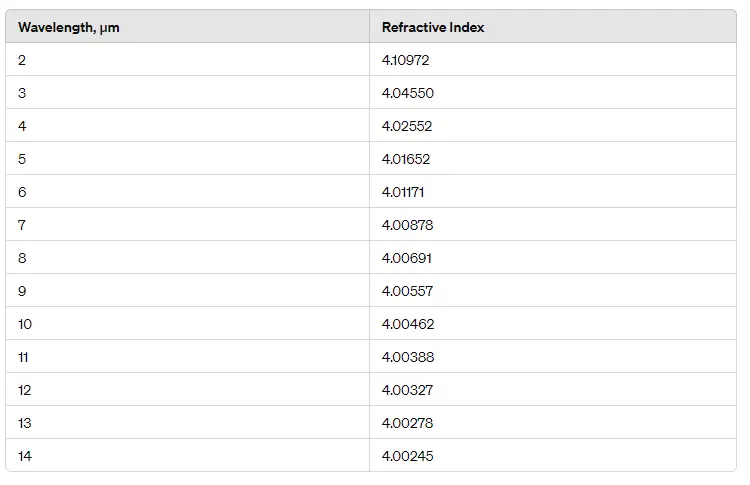

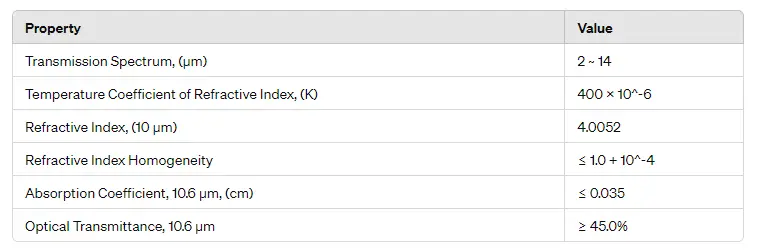

Shape Optics offers Germanium (Ge) windows with three anti-reflection (AR) coating options to suit different infrared (IR) applications: a 3–5 µm coating for mid-infrared (MWIR) use, a 3–12 µm broadband coating for multispectral systems, and an 8–12 µm coating optimized for thermal imaging. Because germanium has a very high refractive index—approximately 4.0 across the 2–14 µm wavelength range—uncoated surfaces exhibit high Fresnel reflection losses. Applying a properly designed AR coating is therefore essential to significantly reduce surface reflections and achieve high transmission within the required spectral band, ensuring optimal performance of infrared optical systems.

Typical transmission of a 3mm thick Ge window with BBAR (3000-5000nm) coating at 0° AOI. It indicates the coating design wavelength range, with the following specification: Ravg <3% @ 3000 - 5000nm

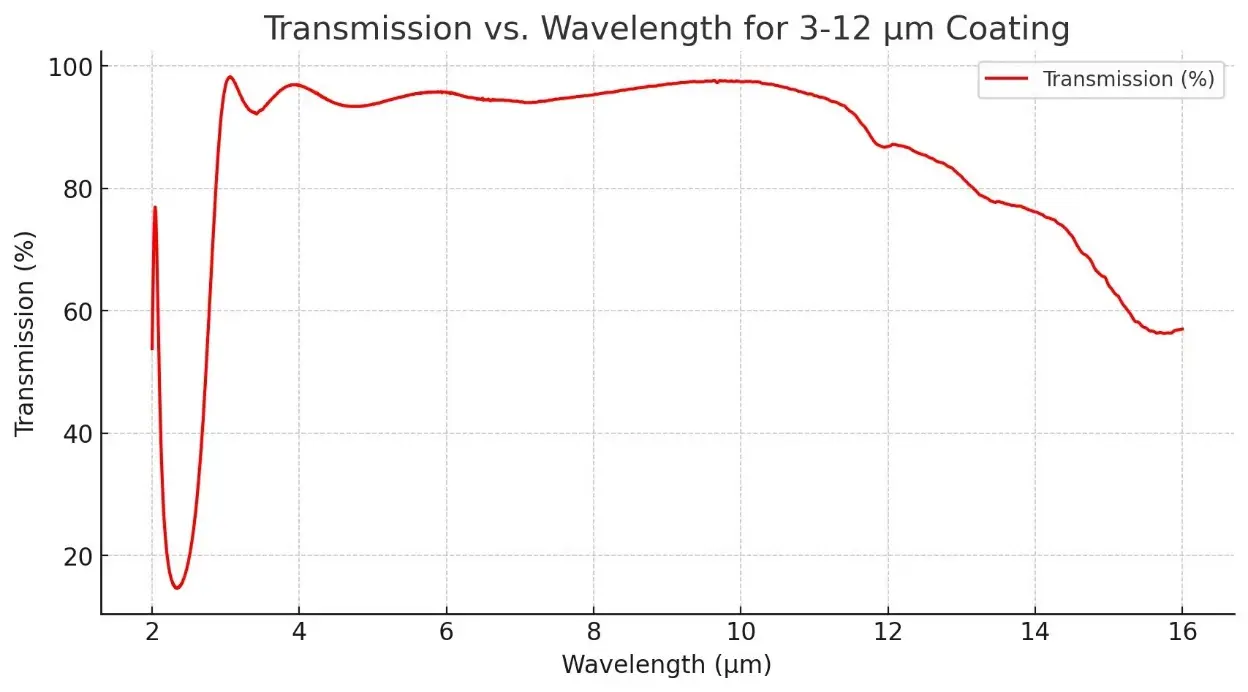

Typical transmission of a 3mm thick Ge window with BBAR (3000-12000nm) coating at 0° AOI. It indicates the coating design wavelength range, with the following specification: Ravg <5.0% @ 3 - 12μm

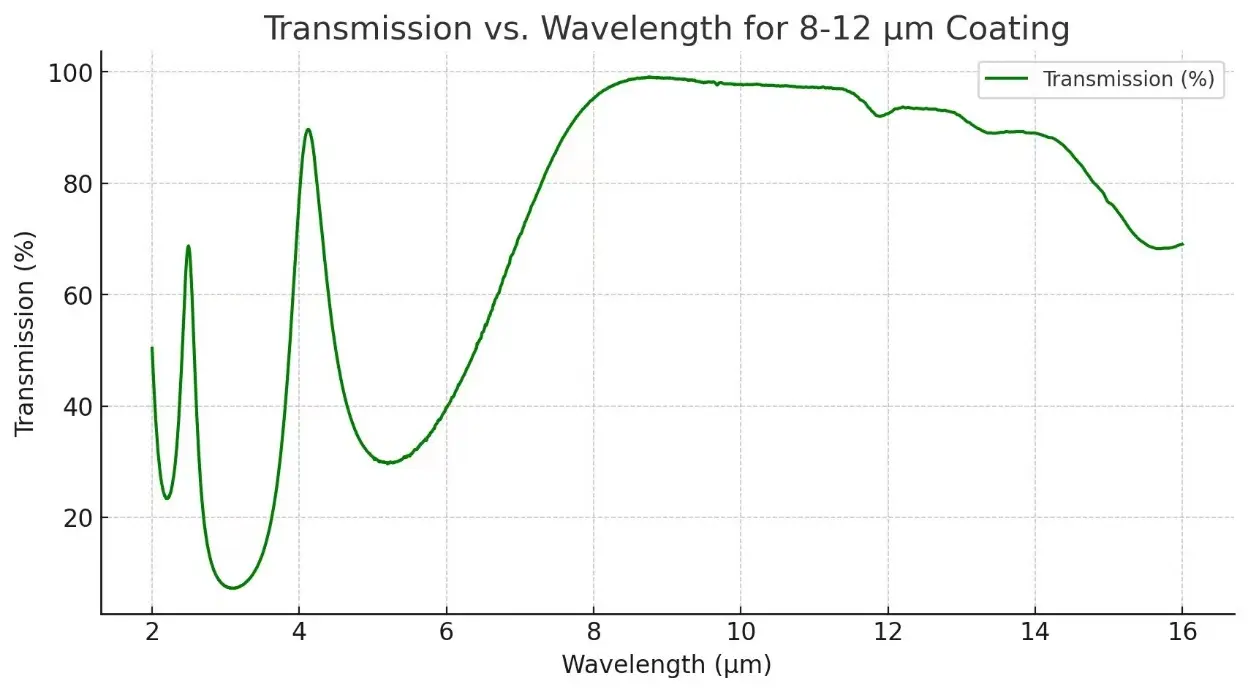

Typical transmission of a 3mm thick Ge window with BBAR (8000-12000nm) coating at 0° AOI. It indicates the coating design wavelength range, with the following specification: Ravg <3.0% @ 8 - 12μm

Germanium is prone to thermal runaway, a condition where its transmission efficiency declines as temperatures rise. Therefore, it is recommended to operate Shape Optics Germanium Windows at temperatures below 100°C to maintain optimal performance. Additionally, with a high density of 5.33 g/cm³, germanium windows should be carefully integrated into designs where weight sensitivity is a factor.

The material’s Knoop Hardness, at 780, is roughly double that of Magnesium Fluoride, making germanium windows exceptionally suitable for demanding IR applications where durable optics are essential.

Polycrystalline Germanium

Monocrystalline Germanium

N-type Germanium

P-type Germanium

Comparison of P-type and N-type Semiconductors

| Feature | P-Type Germanium | N-Type Germanium |

|---|---|---|

| Dopant Elements | Boron, Gallium, Indium | Phosphorus, Arsenic, Antimony |

| Majority Carriers | Holes | Electrons |

| Minority Carriers | Electrons | Holes |

| Carrier Drift Direction (Electric Field) | Holes → negative terminal | Electrons → positive terminal |

| Conventional Current Direction | Positive → negative terminal | Positive → negative terminal |

| Typical Use | P–N junctions, detectors, solar cells | Diodes, transistors, ICs |

Note: While electrons and holes move in opposite physical directions, conventional current always flows from the positive terminal to the negative terminal, regardless of whether the semiconductor is P-type or N-type.

We noticed you're visiting from Singapore. We've updated our prices to Singapore dollar for your shopping convenience. Use United States (US) dollar instead. Dismiss