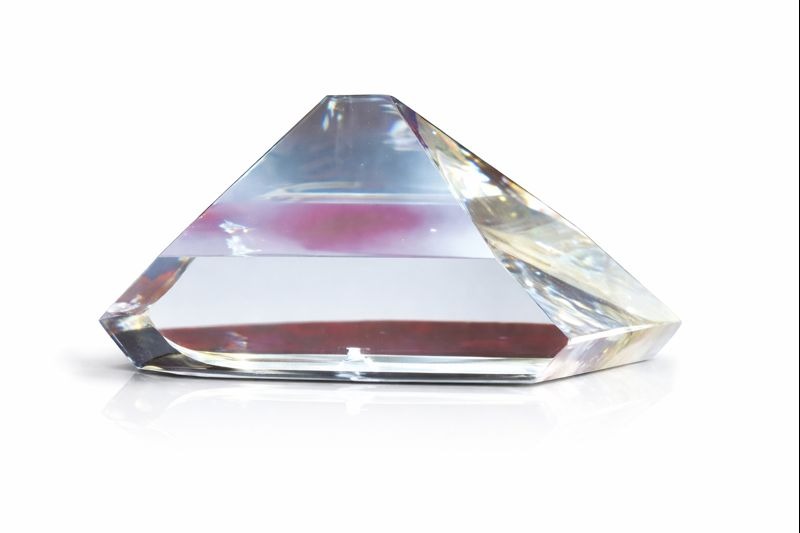

Description

Potassium Titanyl Phosphate (KTP) is a highly versatile optical crystal known for its excellent optical properties and broad transparency range. It is widely used in ultraviolet (UV), visible (VIS), and infrared (IR) optics, making it ideal for a variety of applications including laser technology, frequency doubling, and optical parametric oscillation.

Physical Properties

| Property | Value |

|---|---|

| Crystal Structure | Orthorhombic |

| Point Group | mm2 |

| Space Group | Pna2₁ |

| Lattice Constants, Å | a = 6.404, b = 10.616, c = 12.814, z = 8 |

| Density, g/cm³ | 3.01 |

| Melting Point, °C | 1172 |

| Transition Temperature, °C | 936 |

| Mohs Hardness | 5 |

| Thermal Expansion Coefficients, °C⁻¹ | aₓ = 11×10⁻⁶, aᵧ = 9×10⁻⁶, a��� = 0.6×10⁻⁶ |

| Thermal Conductivity, W/cm·°C | 13 |

| Not Hygroscopic |

Standard Specifications

| Specification | Value |

|---|---|

| Flatness | λ/8 at 633 nm |

| Parallelism | < 20 arcsec |

| Surface Quality | 10 – 5 scratch & dig (MIL-PRF-13830B) |

| Perpendicularity | < 5 arcmin |

| Angle Tolerance | < 30 arcmin |

| Aperture Tolerance | ± 0.1 mm |

| Clear Aperture | 90% of full aperture |

Optical Properties

| Property | Value |

|---|---|

| Transparency | 350–4400 nm |

| Refractive Indices at 1064 nm | nₓ = 1.7404, nᵧ = 1.7479, n𝓏 = 1.8296 |

| Refractive Indices at 532 nm | nₓ = 1.7797, nᵧ = 1.7897, n𝓏 = 1.8877 |

| Thermooptic Coefficients in 0.4 – 1.0 µm Range | ∂nₓ/∂T = 1.1×10⁻⁵ (K⁻¹), ∂nᵧ/∂T = 1.3×10⁻⁵ (K⁻¹), ∂n𝓏/∂T = 1.6×10⁻⁵ (K⁻¹) |

| Wavelength Dispersion of Refractive Indices | nₓ² = 3.0067 + 0.0395/ (λ² – 0.04251) – 0.01247λ², nᵧ² = 3.0319 + 0.04152/ (λ² – 0.04586) – 0.01337λ², n𝓏² = 3.3134 + 0.05694/ (λ² – 0.05941) – 0.01671λ² |

Nonlinear Properties

| Property | Value |

|---|---|

| Phase Matching Range for Type 2 SHG in x-y Plane | 0.99–1.08 µm |

| Phase Matching Range for Type 2 SHG in x-z Plane | 1.1–3.4 µm |

| Phase Matching Range for Type 2, SHG @ 1064 nm, Cut Angle θ=90°, φ=23.5° | |

| Walk-off | 4 mrad |

| Angular Acceptances | Δθ = 55 mrad × cm |

| Angular Acceptances | Δφ = 10 mrad × cm |

| Thermal Acceptance | ΔT = 22 K × cm |

| Spectral Acceptance | Δν = 0.56 nm × cm |

| Up to 80% Extractavity SHG Efficiency | |

| Effective Nonlinearity in x-y Plane | dₑₒₑ = dₒₑₑ = d₁₅sin²φ + d₂₄cos²φ |

| Effective Nonlinearity in x-z Plane | dₒₑₑ = d₂₄sinθ |

| Nonlinear Coefficients | d₃₁ = ± 1.95 pm/V, d₃₂ = ± 3.9 pm/V |

| Nonlinear Coefficients | d₃₃ = ± 15.3 pm/V, d₂₄ = d₃₂, d₁₅ = d₃₁ |

| Damage Threshold | >500 MW/cm² for pulses λ=1064 nm, τ=10 ns, 10 Hz, TEM₀₀ |

Applications

- UV, VIS, and IR Optics: Ideal for ultraviolet, visible, and infrared optics due to its broad transmission range.

- Laser Systems: Used in high-power laser systems for its high damage threshold and excellent optical properties.

- Frequency Doubling: Suitable for frequency doubling applications in lasers, enhancing their efficiency and performance.

- Optical Parametric Oscillation: Employed in optical parametric oscillators for generating tunable laser light.

- Scientific Research: Widely used in research settings for optical experiments and innovations.

Processing and Handling

- Surface Protection: To maintain the integrity of KTP crystals, a protective coating may be applied during handling and processing.

- Machining: Requires careful handling to avoid damage to the crystal structure during milling or other machining processes.

Why Choose Shape Optics?

At Shape Optics, we pride ourselves on our comprehensive expertise and advanced capabilities in the field of optical materials and components. Our commitment to quality and innovation has positioned us as a leader in the industry, serving a diverse range of applications from scientific research to industrial manufacturing.

- Advanced Manufacturing: Shape Optics utilizes state-of-the-art equipment and techniques to ensure the highest precision and quality in our products. Our manufacturing processes are designed to meet the stringent demands of modern optical applications.

- Customization: We understand that every project is unique. Shape Optics offers customized solutions tailored to meet the specific needs of our clients. Whether you require specific dimensions, coatings, or performance characteristics, we have the flexibility to deliver.

- Quality Assurance: Our rigorous quality control processes ensure that every product we deliver meets the highest standards of performance and reliability. Shape Optics is committed to continuous improvement and excellence in all aspects of our operations.

- Expertise and Support: With a team of highly skilled professionals, Shape Optics provides unparalleled technical support and expertise. Our team is dedicated to helping you achieve optimal results in your optical applications.

- Global Reach: Shape Optics serves clients worldwide, providing reliable and timely delivery of products. Our global network ensures that we can meet your needs wherever you are located.

- Sustainability and Responsibility: Shape Optics is committed to sustainable practices and responsible manufacturing. We strive to minimize our environmental impact while delivering high-quality optical solutions.

KTP crystals from Shape Optics represent the pinnacle of quality and performance in optical materials. With our advanced capabilities, commitment to quality, and customer-centric approach, Shape Optics is your ideal partner for all your optical needs. Explore the possibilities with our KTP crystals and experience the Shape Optics difference.