Optical plastic coatings from Shape Optics are designed to enhance the performance and longevity of plastic optical components used in biomedical imaging, optical instruments, digital imaging, and industrial sensing. Applied to PMMA, PC, and related substrates, these coatings deliver high transmission efficiency, stable spectral performance, and robust environmental resistance.

Standard coatings cover 400–1100 nm, while custom solutions can be developed for specific bands (narrow or broadband), UV protection, visible filtering, or near-IR transmission. Coatings integrate seamlessly into lenses, filters, and protective windows, improving device performance and reliability.

Key Features

- High Optical Transmission: Excellent light transmittance across visible to near-IR bands.

- Customized Coating Designs: Tailored transmission wavelengths, optical density (OD), and spectral profiles.

- Broad Application Compatibility: Suitable for lenses, filters, protective windows, and covers.

- Superior Durability: Resistant to humidity, temperature cycling, solvents, and abrasion.

- Flexible Thickness Options: Tunable thickness to fine-adjust transmission without compromising quality.

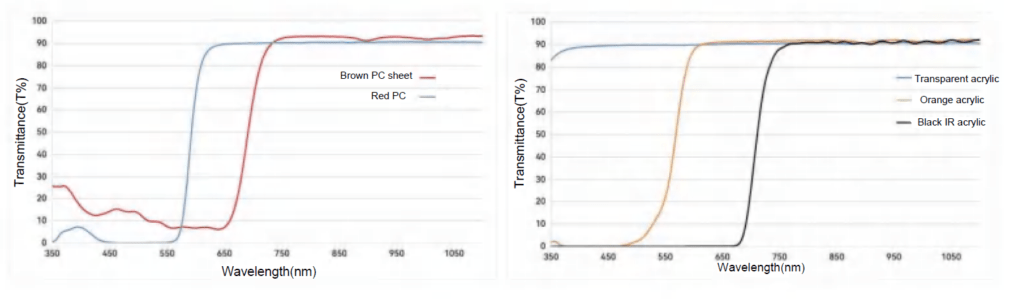

Spectral Transmission Characteristics

High transmittance from 400–1100 nm with minimal loss. Bandpass/longpass/shortpass designs, specific OD levels, and wavelength targeting available on request.

Coating Quality & Reliability Testing

All coatings are qualified to stringent standards to ensure long-term reliability:

- Adhesion: MIL-C-675C (LT-90 tape), no blistering or peeling.

- Temperature Cycling: −62 °C to +71 °C per MIL-C-675C; no film detachment.

- Abrasion Resistance: MIL-C-675C / CCC-C-440, 25 cycles at 1.0 lb, no damage.

- Humidity: 95–100% RH at 49 °C for 24 h, no defects.

- Solvent Resistance: Stable after acetone and alcohol exposure and cleaning.

- Salt Spray: 100 h at 35 °C in 5% saline, no degradation.

Standard Specifications

| Model | Transmission | Wavelength (nm) | Optical Density |

|---|---|---|---|

| Transparent Acrylic | ≥88% | 400–1100 | OD ≥3 @ 200–1100 |

| Orange Acrylic | ≥90% | 630–1100 | OD ≥3 @ 350–460 |

| Red Acrylic | ≥90% | 650–1100 | OD ≥3 @ 350–490 |

| Black IR Acrylic | ≥90% | 800–1100 | OD ≥3 @ 350–510 |

| Transparent PC | ≥88% | 400–1100 | OD ≥3 @ 350–490 |

| Brown PC | ≥90% | 780–1100 | OD ≥3 @ 350–500 |

| Black IR PC | ≥90% | 850–1100 | OD ≥3 @ 350–520 |

Custom materials, bands, and OD targets available.

Applications

- Biomedical Imaging: Medical imaging, diagnostics, and laser-assisted systems requiring high clarity and spectral control.

- Fingerprint Recognition: Optimized reflection/transmission for higher recognition accuracy.

- Digital Imaging: Cameras and imaging devices to reduce glare and enhance image quality.

- Industrial & Machine Vision: Durable optics for spectroscopy, sensing, and harsh environments.

- Photovoltaics: Enhanced light transmission and reduced reflection for solar applications.

SOT Strengths & Capabilities

- Advanced coating design and application facilities

- Custom spectral engineering (wavelength, OD, bandwidth)

- Proven durability to military/industrial standards

- End-to-end support from design to production

- Cost-effective solutions for OEM and high-volume programs