An Optical Germanium Infrared (IR) Dome is a precision optical component specifically designed for infrared systems that require a wide field of view combined with environmental protection. Manufactured from germanium, these dome-shaped optics are widely used in advanced IR imaging, sensing, and guidance systems where both optical performance and mechanical robustness are critical.

Properties of Germanium IR Domes

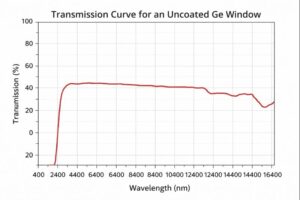

- Infrared Transmission: Germanium provides excellent transmission across the 2–14 µm wavelength range, covering both MWIR and LWIR bands.

- Dome Geometry: The hemispherical or dome shape enables a very wide field of view, often approaching panoramic coverage, while also reducing optical distortion during scanning or tracking.

- High Refractive Index: With a refractive index of approximately 4.0 at 10.6 µm, germanium allows effective IR light control even with relatively thin dome walls, supporting compact system designs.

- Mechanical Strength: Germanium is a dense and mechanically robust material. While inherently brittle, the dome geometry helps distribute mechanical stress more evenly than flat windows, improving survivability.

- Thermal Sensitivity: Germanium’s refractive index and absorption vary with temperature. Optical designs must account for this behavior, particularly in high-speed or outdoor applications with rapid thermal changes.

Coating Options for Germanium IR Domes

- Anti-Reflective (AR) Coatings: Due to germanium’s high refractive index, uncoated surfaces exhibit significant Fresnel losses. AR coatings are essential to minimize reflection and maximize transmission within the required IR band (e.g., 3–5 µm, 8–12 µm, or broadband).

- Durable Protective Coatings (eg., DLC): For harsh environments, Diamond-Like Carbon (DLC) or similar hard coatings may be applied to enhance abrasion resistance, moisture resistance, and environmental durability while maintaining acceptable IR transmission.

Manufacturing Process of Germanium IR Domes

Producing a germanium IR dome is a highly specialized process requiring precision equipment and skilled craftsmanship.

1. Raw Material Preparation

- Purification: High-purity germanium is produced by reducing germanium dioxide (GeO₂) to elemental germanium.

- Crystal Growth: Single-crystal germanium is grown using controlled processes such as Czochralski or zone melting, ensuring optical-grade crystal quality.

2. Blank Preparation

- Cutting and Shaping: Crystal boules are cut into rough blanks.

- Preforming: CNC machining is used to form the preliminary dome geometry.

3. Fine Grinding and Polishing

- Grinding: Diamond-based tools refine the dome geometry.

- Polishing: Optical polishing achieves high surface quality and transmission performance.

4. Coating

- AR Coating: Applied to improve IR transmission and reduce reflection.

- Protective Coating: Optional coatings improve resistance to abrasion, moisture, and environmental stress.

(Example: The graph below shows Ge dome without AR coating @ 5 mm thickness)

5. Inspection and Quality Control

- Surface inspection for scratches, digs, and inclusions.

- Optical testing for transmission, reflection, and absorption.

- Environmental testing for temperature, humidity, and mechanical stress.

6. Assembly (If Required)

Precision mounting into housings or frames for final system integration

Shape Optics Germanium (Ge) Crystals Specifications

| Attribute | Details |

|---|---|

| Diameter | 12mm ~ 380mm |

| Length | Customizable |

| Electrical Resistivity | 5 – 40 Ω·cm (optical grade) |

| Crystal Structure | Single Crystal / Polycrystalline |

| Crystal Purity | 99.999% ~ 99.99999% |

| Conduction Type | N-type / P-type |

| Surface Roughness | Ra max 0.2µm – 4.0µm |

| Refractive Index @ 10.6µm | 4.0052 |

| Absorptance @ 10.6µm | ≤0.035 |

Factory Standard (Reference)

- Diameter range: 2 mm – 100 mm

- Diameter tolerance: +0 / −0.05 mm

- Thickness tolerance: +0.01 / −0.03 mm

- Flatness: 1/2 λ

- Parallelism: < 3 arc minutes

- Surface quality: 20-10 scratch-dig (no dig)

- Edge finish: Protective bevel

- Transmission: >47.5% @ 3.7–4.8 µm (uncoated)

(Higher transmission achievable with AR coatings or custom designs)

Contact us for manufacturing limits or custom specifications.

Applications of Optical Germanium Infrared IR Dome

- Security and Surveillance: One of the primary applications of germanium IR domes is in security cameras equipped with thermal imaging capabilities. The dome shape allows for uninterrupted panoramic viewing.

- Military Equipment: In military applications, these domes are used in devices that require robust, wide-angle infrared vision, such as in missile guidance systems and in armored vehicle vision systems.

- Thermal Imaging: Broadly, any thermal imaging system that needs a protective, wide-angle window might use a germanium IR dome. This includes industrial systems used for monitoring equipment or processes.

- Environmental and Weather Monitoring: Systems that track environmental conditions or weather phenomena often use IR domes to protect their sensitive IR sensors while providing a broad field of view.