Key Features

- Material Grade: UV, Deep UV, Extreme UV, Excimer Laser, Low Stress

- Maximum Crystal Size: Ø200mm

- Growing Method: Czochralski (CZ)

- Crystal Structure: Monocrystalline

- Cleavage Planes: <110>

- Common Crystal Orientation: <001>, <100>, <111>

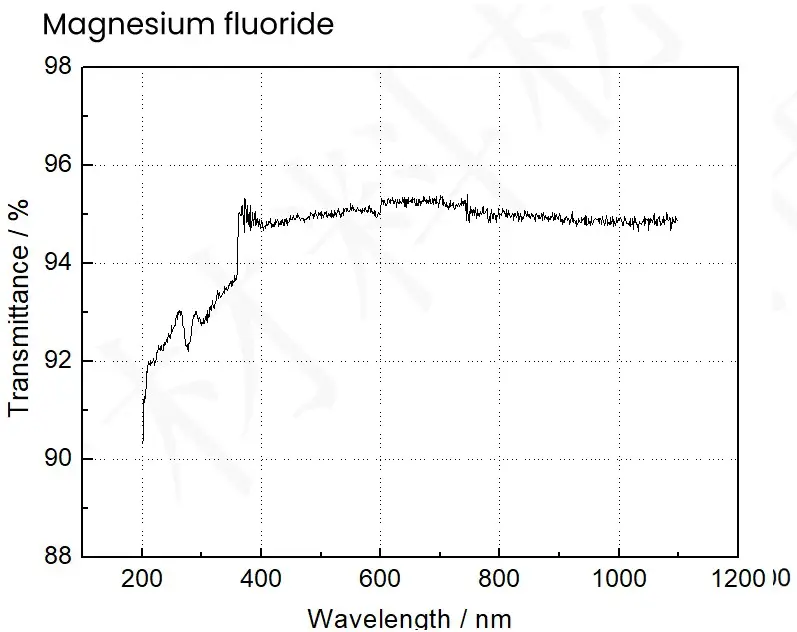

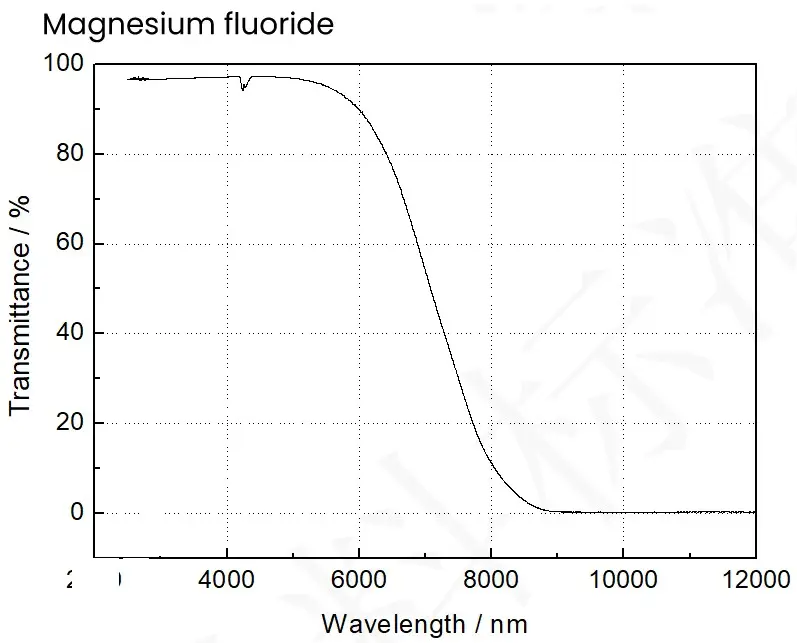

- Transmittance Range: 110nm – 7.5μm

- Transmittance: >90% @ 193nm – 6μm

Description

Magnesium fluoride (MgF₂) is a birefringent crystal with excellent optical properties, commonly used as a polarizing element. It has very high transmittance in the UV band and is one of the best optical crystals available in the UV cut-off band. Due to its excellent transmittance in the UV, visible, and IR fields, MgF₂ is widely used in scientific and technological applications such as lasers, IR optics, UV optics, and high-energy detectors.

Physical Properties

| Property | Specification |

|---|---|

| Material Grade | UV, Deep UV, Extreme UV, Excimer Laser, Low Stress |

| Maximum Crystal Size | Ø200mm |

| Growing Method | Czochralski (CZ) |

| Crystal Structure | Monocrystalline |

| Cleavage Planes | <110> |

| Common Crystal Orientation | <001>, <100>, <111> |

Optical Properties

| Property | Specification |

|---|---|

| Transmittance Range | 110nm – 7.5μm |

| Transmittance | >90% @ 193nm – 6μm |

Standard Specifications

| Property | Specification |

|---|---|

| Material | Magnesium Fluoride (MgF₂) |

| Wavelength Range | 110nm – 7.5μm |

| Crystal Orientation | <001>, <100>, <111> |

| Transmittance | >90% @ 193nm – 6μm |

Other Properties

- Thermal Stability: High thermal stability, suitable for environments with varying temperatures.

- Chemical Resistance: Resistant to various chemicals, ensuring durability in different working conditions.

Applications

Magnesium fluoride crystals are ideal for use in laser systems, optical communication, imaging systems, and scientific research. They are particularly useful in applications requiring high transmittance and polarization control, such as UV optics, IR optics, and high-energy detectors. Additionally, MgF₂ is used in polarizing elements and waveplates due to its birefringence.

Processing and Handling

Our magnesium fluoride crystals undergo rigorous quality control and precision manufacturing processes. Handling instructions are provided to maintain the optical integrity of the crystals during installation and use. Proper cleaning and storage procedures are recommended to preserve the high surface quality and performance.

Why Choose Shape Optics

Shape Optics is dedicated to providing high-precision optical components that meet the highest standards of quality and performance. Our extensive experience and state-of-the-art manufacturing facilities ensure that we can deliver custom solutions tailored to your specific needs.

Shape Optics Strength and Capabilities

- Advanced Manufacturing Technology: Utilization of cutting-edge technology in the production of optical components.

- High Precision and Quality Control: Stringent quality control measures to ensure the highest level of precision and performance.

- Customizable Solutions: Ability to offer tailored solutions to meet diverse optical requirements.

- Expertise in a Wide Range of Optical Materials and Applications: Comprehensive knowledge and experience in various optical materials and their applications.

For more information about our magnesium fluoride crystals and other optical components, please contact Shape Optics or visit our website.