Machine vision filters from Shape Optics Technologies Pte Ltd are engineered to enhance imaging accuracy in industrial automation, quality inspection, and scientific vision systems. By selectively transmitting specific wavelength bands, these filters improve contrast, suppress ambient light interference, and enable reliable feature detection.

Manufactured using advanced dielectric coating technologies, SOT machine vision filters provide high transmission, strong blocking (OD ≥ 3), and long-term environmental stability. They are compatible with common illumination sources such as LEDs and lasers, and can be optimized for monochrome or color camera systems. Custom configurations are available to support unique lighting conditions and imaging requirements.

Key Features

- High-Precision Bandpass Filtering – Accurate wavelength selection for superior image contrast and repeatability

- Wide Wavelength Coverage – Standard center wavelengths from 405 nm to 940 nm

- Excellent Transmission Efficiency – Peak transmittance ≥ 90% for maximum signal throughput

- Stable Optical Performance – Low temperature shift and strong out-of-band blocking

- Customizable Designs – Size, optical density, bandwidth, and coatings tailored to system needs

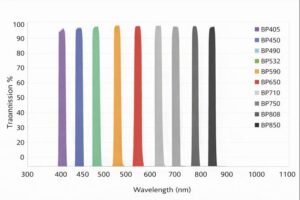

Spectrum Transmission

Standard models are optimized for popular machine vision wavelengths including 405 nm, 450 nm, 490 nm, 532 nm, 590 nm, 650 nm, 710 nm, 750 nm, and NIR bands. Each filter features a well-defined passband with steep spectral edges.

Custom wavelength ranges and optical densities are available upon request.

Coating Quality & Environmental Reliability

All machine vision filters are qualified to rigorous standards:

- Adhesion (MIL-C-675C) – No blistering or peeling after repeated tape removal

- Thermal Cycling – −62 °C to +71 °C with no coating detachment

- Abrasion Resistance (MIL-C-675C / CCC-C-440) – No surface damage after 25 cycles

- Humidity Resistance – 95–100% RH at 49 °C for 24 hours without defects

- Solvent Resistance – Stable after acetone and alcohol exposure

- Salt Spray Test – 100 hours at 35 °C, 5% salt concentration with no degradation

Standard Specifications

| Model | CWL (nm) | Peak Transmittance | FWHM (nm) | Optical Density | Notes |

|---|---|---|---|---|---|

| NH-BP405/20 | 405 ± 3 | ≥ 90% | 20 ± 5 | OD ≥ 3 @ 350–1100 | Custom sizes available |

| NH-BP450/20 | 450 ± 3 | ≥ 90% | 20 ± 5 | OD ≥ 3 @ 350–1100 | Custom sizes available |

| NH-BP460/20 | 460 ± 3 | ≥ 90% | 20 ± 5 | OD ≥ 3 @ 350–1100 | Custom sizes available |

| NH-BP490/20 | 490 ± 3 | ≥ 90% | 20 ± 5 | OD ≥ 3 @ 350–1100 | Custom sizes available |

| NH-BP520/20 | 520 ± 3 | ≥ 90% | 20 ± 5 | OD ≥ 3 @ 350–1100 | Custom sizes available |

| NH-BP532/20 | 532 ± 3 | ≥ 90% | 20 ± 5 | OD ≥ 3 @ 350–1100 | Laser-compatible |

| NH-BP550/20 | 550 ± 3 | ≥ 90% | 20 ± 5 | OD ≥ 3 @ 350–1100 | Imaging systems |

| NH-BP650/20 | 650 ± 3 | ≥ 90% | 20 ± 5 | OD ≥ 3 @ 350–1100 | Red illumination |

| NH-BP750/20 | 750 ± 3 | ≥ 90% | 20 ± 5 | OD ≥ 3 @ 350–1100 | NIR applications |

Typical Applications

- Quality Inspection & Automation – Accurate detection of defects, marks, and features

- Machine Learning & Vision AI – Improved spectral consistency for training and recognition

- Biometric Identification – Face, fingerprint, and pattern recognition systems

- Medical & Scientific Imaging – Controlled spectral imaging for diagnostics and analysis

Need a custom machine vision filter?

Contact us with your illumination wavelength, camera type, bandwidth, OD target, and mechanical constraints for a tailored solution.