Laser Welding and Cutting Filters are precision optical windows engineered for high-power industrial laser processing. These filters ensure efficient transmission of the working laser wavelength while protecting optical systems from unwanted radiation and environmental exposure.

Manufactured from high-purity quartz, the filters provide outstanding optical clarity, thermal resistance, and mechanical robustness—critical for laser welding, cutting, and micromachining systems. Optimized designs for 355 nm (UV) and 1064 nm (IR) enable maximum energy throughput with minimal loss, ensuring clean cuts, strong welds, and consistent process quality.

Key Features

- Optimized for High-Power Lasers – Designed for demanding laser welding and cutting operations

- Precise Wavelength Control – Optimized for industrial laser lines such as 355 nm and 1064 nm

- Ultra-High Transmission – Tave ≥ 99.5% to maximize laser energy delivery

- Quartz Substrate Durability – Excellent thermal stability and resistance in high-heat environments

- Customizable Designs – Coatings, sizes, and spectral ranges tailored to your system

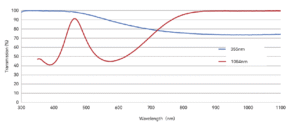

Spectrum Transmission

Standard designs feature highly selective transmission curves centered at 355 nm and 1064 nm, delivering ultra-high in-band transmission while suppressing unwanted wavelengths.

Custom transmission profiles are available for non-standard laser lines or hybrid systems.

Coating Parameters

| Parameter | Value |

|---|---|

| Transmittance | T ≥ 90%, T ≥ 95% (Customization available upon request) |

| Center Wavelength (CWL) | Typical wavelengths: 520 nm, 635 nm, 650 nm, 808 nm, 905 nm, 940 nm (selection based on customer’s requirements) |

| Bandwidth (FWHM) | 10–150 nm (selection based on customer’s requirements) |

| Optical Density (OD) | OD ≥ 3, OD ≥ 4 (customizable) |

| Dimension | Process as per customer’s requirements |

| Thickness | Convention: 0.33 mm, 0.55 mm, 0.7 mm, 1.0 mm, 1.1 mm (customizable) |

| Note | For more in-stock models, please feel free to contact us. |

Typical Laser Welding and Cutting Protective Filter

| Model | Material | Surface Quality | Transmission Wavelength (nm) | Transmittance | Note |

|---|---|---|---|---|---|

| 365nm Optical Window | Fused Silica | 40/20 | 350–360 | T ≥ 99.5% | Customizable |

| 1064nm Optical Window | Fused Silica | 40/20 | 1050–1080 | T ≥ 99.5% | Customizable |

Applications

- Industrial Manufacturing – Precision laser welding and cutting of metals

- Automotive Production – High-strength welding of body and structural components

- Electronics Manufacturing – Clean laser cutting of PCBs and micro-components

- Medical Device Manufacturing – Precision laser processing with minimal thermal damage

- Aerospace Industry – High-accuracy cutting and welding of critical components

Need a custom laser welding or cutting filter?

Contact us with your laser wavelength, power level, window size, and operating conditions for a tailored solution.