Laser Marking Windows are precision optical components engineered to enhance performance in laser marking and engraving systems. These windows ensure efficient transmission of required wavelengths while selectively reflecting or blocking others, improving marking accuracy and protecting sensitive CCD imaging modules.

Manufactured from high-quality quartz, SOT laser marking windows offer excellent thermal stability, durability, and optical clarity. They are commonly used in systems operating at 355 nm and 1064 nm, where controlled separation of laser and visible imaging light is essential for precise alignment and high-definition marking.

Key Features

- Optimized for Laser Marking – Designed to deliver sharp, high-contrast marking with minimal optical distortion

- High Transmission Efficiency – Excellent transmission for visible and IR wavelengths, ideal for CCD imaging systems

- Selective Spectral Control – Precisely transmits target wavelengths while reflecting unwanted bands

- Durable Quartz Substrate – High mechanical strength and thermal stability for harsh industrial environments

- Customizable Designs – Wavelength, coating function, and dimensions tailored to system requirements

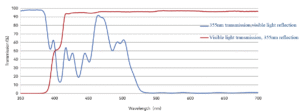

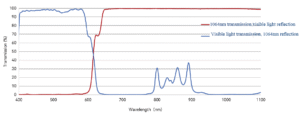

Spectrum Transmission

Laser marking windows feature highly selective transmission curves, optimized to transmit laser wavelengths (e.g. 355 nm or 1064 nm). Custom spectral designs are available upon request.

Typical Laser Marking Window

| Model | Incidence Angle | Transmittance | Transmission Wavelength (nm) | Reflectivity | Reflection Wavelength (nm) |

|---|---|---|---|---|---|

| 355 nm Transmission, Visible Light Reflection | 45° | T ≥ 95% | 350–360 | Ravg ≥ 99% | 600–700 |

| Visible Light Transmission, 1064 nm Reflection | 45° | T ≥ 95% | 430–700 | Ravg ≥ 99% | 350–360 |

| 1064 nm Transmission, Visible Light Reflection | 45° | T ≥ 98% | 1050–1080 | Ravg ≥ 99% | 400–580 |

| Visible Light Transmission, 1064 nm Reflection | 45° | T ≥ 95% | 400–580 | Ravg ≥ 99% | 1050–1080 |

Applications

- Electronics Manufacturing – High-precision PCB and component marking

- Automotive Industry – Durable labeling of parts and assemblies

- Medical Devices – Permanent marking of surgical tools and implants

- Material Processing – Laser marking and cutting with CCD alignment

- Consumer Goods – Branding and traceability marking with high clarity

Need a custom laser marking window?

Contact us with your laser wavelength, imaging requirements, substrate size, and operating conditions for a tailored solution.