Infrared Zinc Selenide (ZnSe) is a compound semiconductor widely recognized for its excellent infrared transmission, low absorption, and strong thermal stability. With high transparency across the mid-wave infrared (MWIR) and long-wave infrared (LWIR) regions, ZnSe is a preferred material for precision optical components, including lenses, windows, prisms, and laser optics.

ZnSe is extensively used in thermal imaging systems, infrared spectroscopy, and high-power laser applications, particularly CO₂ laser systems, where optical clarity and resistance to thermal shock are critical. Its reliable performance in demanding environments makes Zinc Selenide a cornerstone material in modern infrared optical engineering.

Key Advantages of Infrared Zinc Selenide (ZnSe)

- Broad Infrared Transmission: High transparency from visible to long-wave infrared wavelengths

- Low Absorption Coefficient: Suitable for high-power and laser-based applications

- Excellent Thermal Shock Resistance: Performs reliably in harsh and high-temperature environments

- Coating Compatibility: Supports AR and DLC coatings for improved transmission and durability

- Manufacturing Flexibility: Available in flat, spherical, and aspheric optical forms

Applications of Infrared Zinc Selenide (ZnSe)

- Infrared Optics: Used for lenses, windows, and prisms in thermal imaging systems, night vision devices, and infrared spectroscopy due to excellent MWIR and LWIR transmission.

- Laser Systems: Widely applied as lenses and windows in high-power laser systems, especially CO₂ lasers operating in the mid-infrared range.

- Medical Imaging & Diagnostics: Utilized in infrared spectroscopy and thermal imaging systems for medical diagnostics, research, and patient monitoring.

- Defense & Security Systems: Employed in surveillance optics, target acquisition, missile guidance, and military-grade infrared imaging systems.

- Environmental Monitoring: Used in sensors and optical instruments for atmospheric gas detection, pollutant monitoring, and remote sensing applications.

- Industrial Process Control: Applied in infrared spectroscopy systems for real-time chemical analysis, temperature monitoring, and quality control in manufacturing environments.

General Manufacturing Specifications – ZnSe Optical Components

Flat Shape (Windows & Plates)

Material Options: Ge, Si, ZnSe, ZnS, Chalcogenide Glasses

| Parameter | Specification |

|---|---|

| Diameter Tolerance | ≤ 0.03 mm |

| Curvature Radius | ΔSag < 0.005 |

| Center Thickness Tolerance | ≤ 0.025 mm |

| Edge Thickness | ≤ 0.03 mm |

| Surface Quality | 40/20 |

| Transmittance | AR ≥97% / DLC+AR ≥90% |

| Surface Power | N < 2, ΔN < 1 |

| Flatness | < 10 μm |

| Decentration | Window ≤30′ / Lens ≤1.5′ |

Spherical Shape (Lenses)

Diameter Range: 12 mm – 450 mm

| Parameter | Specification |

|---|---|

| Diameter Tolerance | 0.05 mm |

| Center Thickness Tolerance | 0.02 mm |

| Surface Quality | 20/10, 10/5 |

| Surface Accuracy | PV λ/10, λ/20 |

| Surface Roughness | Ra ≤0.04 μm |

| Local Error | ≤0.5 |

| Decentration | ≤1′ |

| Total Height Tolerance | ±0.02 mm |

| Concave Sag | ±0.02 mm |

Aspheric Shape (Precision IR Optics)

Aspheric Turning Diameter: 12 mm – 200 mm

| Parameter | Specification |

|---|---|

| Diameter Tolerance | 0.05 mm |

| Center Thickness Tolerance | 0.02 mm |

| Surface Quality | 20/10, 10/5 |

| Surface Accuracy | PV λ/10, λ/20 |

| Surface Roughness | Ra ≤0.04 μm |

| Local Error | ≤0.5 |

| Decentration | ≤1′ |

| Total Height Tolerance | ±0.02 mm |

| Concave Sag | ±0.02 mm |

Shapeoptics Infrared ZnSe Capabilities

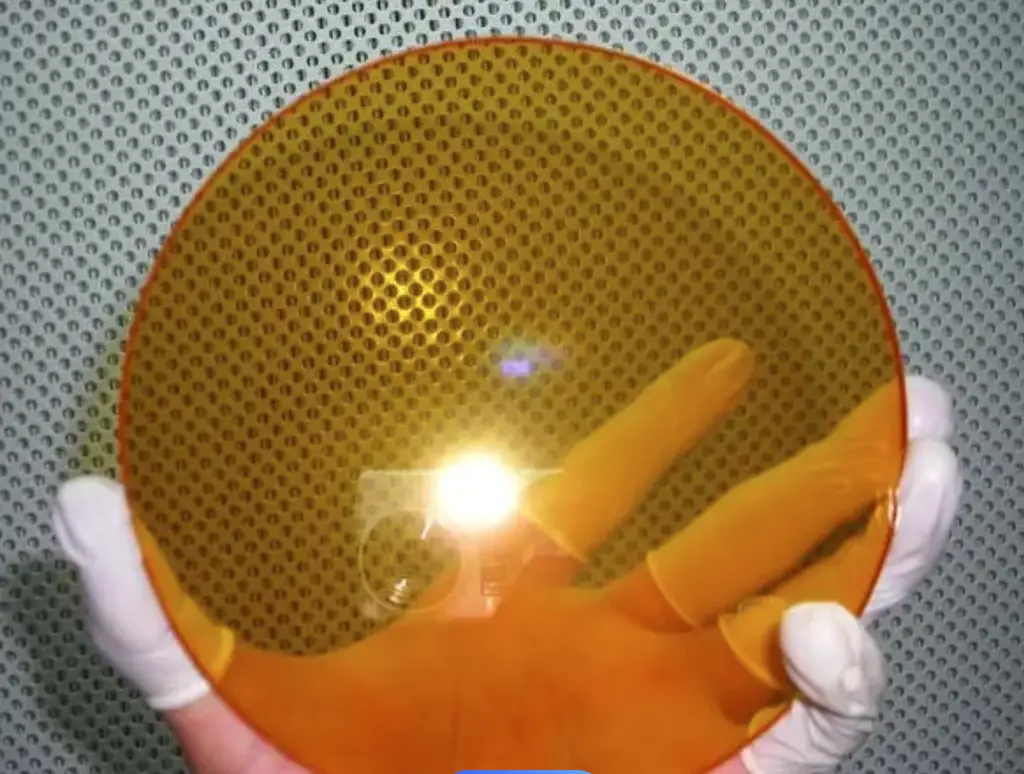

Shape Optics Technologies works with advanced manufacturing partners to deliver high-quality Infrared Zinc Selenide (ZnSe) optical components, produced using state-of-the-art equipment and precision fabrication techniques.

With more than 20 years of optical manufacturing expertise, Shapeoptics provides reliable, high-performance ZnSe optics tailored to demanding infrared applications.