Infrared temperature measurement filters are engineered for infrared thermometers and non-contact temperature sensing systems. Built on a monocrystal silicon substrate, these filters leverage advanced coating technologies to deliver high cutoff depth and excellent transmittance within the required IR band.

By selectively transmitting the relevant infrared wavelengths (typically 780–1500 nm) while suppressing out-of-band radiation, the filter ensures that only meaningful thermal signals reach the photodetector. This improves signal-to-noise ratio and measurement precision across industrial, medical, and scientific applications.

Key Features

- High Cutoff Depth – Precisely blocks unwanted wavelengths to improve temperature-reading accuracy

- Monocrystal Silicon Substrate – Excellent stability, uniformity, and long-term reliability

- High Transmittance – Optimized throughput for efficient IR energy detection

- Broad IR Coverage – Designed for 780–1500 nm, ideal for IR thermometry

- Customization Available – Tailored passbands, OD levels, and dimensions to match system needs

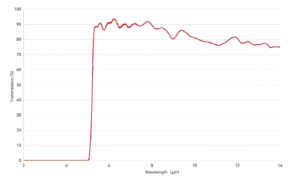

Spectrum Transmission

Standard designs provide optimized transmission across 780–1500 nm. When standard components do not meet application requirements, custom spectral designs—including alternate passbands and higher blocking—are available upon request.

Standard Specifications

| Model | Transmittance | Transmission Wavelength (nm) | Optical Density |

|---|---|---|---|

| Infrared Temperature Measurement Filter | T ≥ 90% | 780–1500 | OD ≥ 3 @ 350–1100 |

Additional OD levels and wavelength ranges available on request.

Applications

- Infrared Thermometers – Accurate non-contact temperature sensing

- Industrial Manufacturing – Process monitoring and quality control

- Medical Diagnostics – Non-invasive temperature screening

- Scientific Research – Thermal analysis and radiation studies

- Environmental Monitoring – Fire detection, geothermal and field measurements

Need a custom infrared temperature measurement filter?

Contact us with your system details for a tailored solution.