Double-Band Bandpass Filters from Shape Optics are engineered to transmit two targeted wavelength regions simultaneously, making them ideal for optical systems that require multi-spectral isolation from a single optical path.

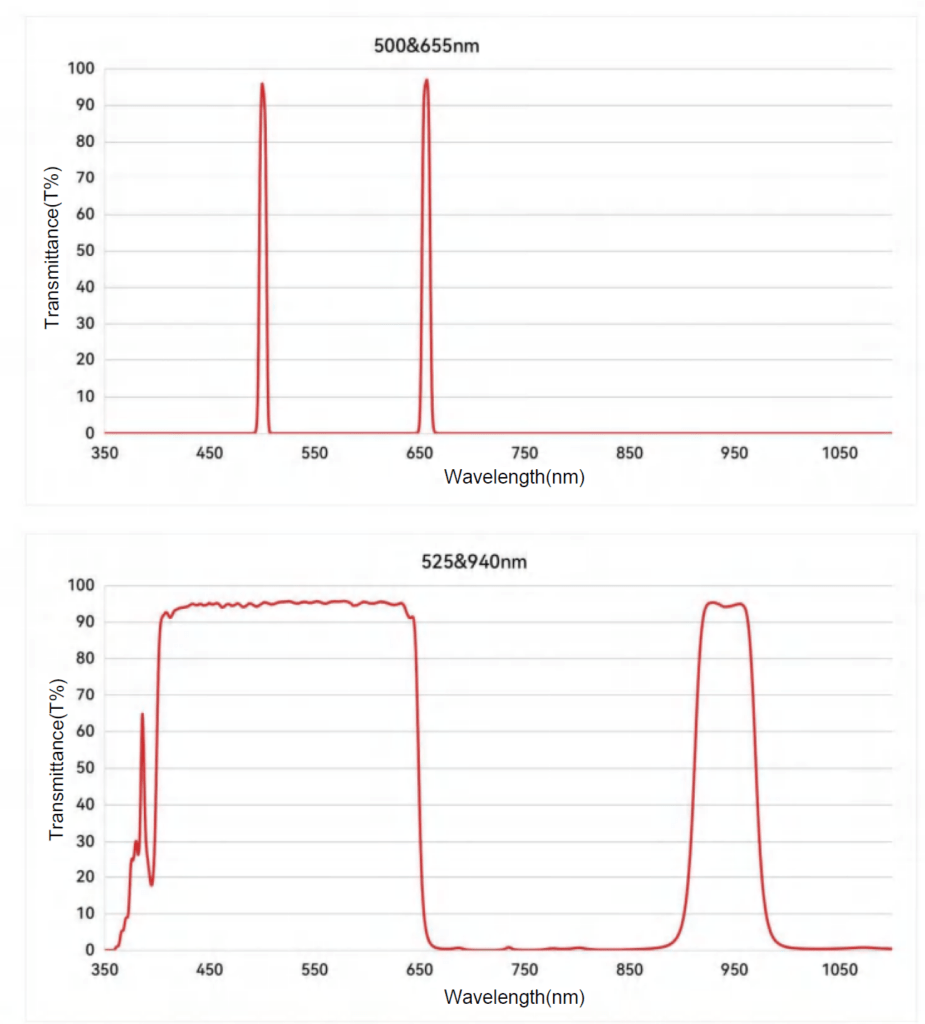

These filters combine high transmission with deep blocking, enabling clean signal separation in applications such as fluorescence microscopy, spectral analysis, imaging systems, and laser-based instrumentation. Standard configurations include popular wavelength pairs such as 500 & 655 nm and 525 & 940 nm, while fully customized designs are available to meet specialized requirements.

Key Features

- Dual-Band Functionality – Precisely transmits two distinct wavelength bands while blocking all others

- High Transmittance – T ≥ 90% in passbands for maximum signal efficiency

- Strong Out-of-Band Blocking – OD ≥ 3 ensures excellent background suppression

- Customizable Spectral Design – CWL, bandwidth, and OD tailored to your application

- High Precision & Stability – Tight tolerances for reliable performance in sensitive optical systems

Spectrum Transmission

Standard double-band designs provide two well-defined transmission windows with steep spectral edges. If standard wavelength combinations do not meet your needs, custom spectral solutions can be developed based on your required center wavelengths, bandwidths (FWHM), and blocking ranges.

Coating Parameters

| Parameter | Value |

|---|---|

| Transmittance | T ≥ 90%, T ≥ 95% (Customization available upon request) |

| Wavelength (CWL) | 200 nm – 2500 nm (Selection based on customer’s requirements) |

| Bandwidth (FWHM) | 5–250 nm (Selection based on customer’s requirements) |

| Optical Density (OD) | OD2, OD3, OD4 (Customization available) |

| Dimension | Customized on request (Aluminum oxide rings can be added as needed) |

| Note | For more models in stock, please contact us. |

Common Double-band Bandpass Filter

| Model | Wavelength (nm) | Bandwidth (FWHM, nm) | Model | Wavelength (nm) | Bandwidth (FWHM, nm) |

|---|---|---|---|---|---|

| 310 & 400 nm Dual-Bandpass | 310 ± 2 & 400 ± 2 | 10 ± 2 & 20 ± 2 | 1202 & 1300 nm Dual-Bandpass | 1202 ± 5 & 1300 ± 5 | 30 ± 5 & 30 ± 5 |

| 500 & 655 nm Dual-Bandpass | 500 ± 2 & 655 ± 2 | 10 ± 2 & 20 ± 2 | 1205 & 1302 nm Dual-Bandpass | 1205 ± 5 & 1302 ± 5 | 30 ± 5 & 30 ± 5 |

| 525 & 850 nm Dual-Bandpass | 525 ± 10 & 850 ± 5 | 250 ± 20 & 50 ± 10 | 1208 & 1300 nm Dual-Bandpass | 1208 ± 5 & 1300 ± 5 | 30 ± 5 & 30 ± 5 |

| 525 & 940 nm Dual-Bandpass | 525 ± 10 & 940 ± 5 | 250 ± 20 & 50 ± 10 | 450 & 550 & 650 Triple Bandpass | 450 ± 5 & 550 ± 5 & 650 ± 5 | 30 ± 5 & 30 ± 5 & 30 ± 5 |

| 660 & 860 nm Dual-Bandpass | 660 ± 5 & 860 ± 5 | 35 ± 5 & 50 ± 5 | 550 & 720 & 850 Triple Bandpass | 550 ± 5 & 720 ± 5 & 850 ± 5 | 30 ± 5 & 15 ± 5 & 30 ± 5 |

Note: The inventory of the dual-bandpass filters may change in real-time. For more parameters, please feel free to contact us.

Applications

- Fluorescence Microscopy – Isolation of excitation and emission bands

- Laser Systems – Dual-wavelength laser separation or detection

- Astronomy & Spectroscopy – Targeted spectral line observation

- Environmental Monitoring – Multi-band detection of gases or pollutants

- Industrial Optical Systems – Multi-spectral inspection and analysis

Need a custom double-band bandpass filter?

Contact us with your desired specifications and system details for a tailored solution.