Dichroic filters are precision optical components designed to transmit selected wavelengths while reflecting others. They are indispensable in optical systems where accurate wavelength separation is required, such as microscopy, spectroscopy, imaging systems, and laser optics.

The dichroic filter is optimized for high transmission efficiency and high reflectivity, enabling clean spectral separation with minimal loss. Manufactured using high-quality substrates and advanced multilayer dielectric coatings, these filters deliver stable performance even in demanding environments.

Key Features

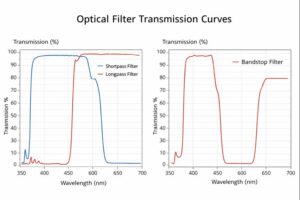

- High Precision Transmission – Excellent spectral selectivity with sharp cut-on / cut-off edges

- Superior Reflectivity – Up to 98% reflectance in designated reflection bands

- Wide Spectral Coverage – Models spanning visible to near-infrared wavelengths

- High Durability – Robust dielectric coatings for long-term stability

- Customizable Designs – Transmission bands, reflectivity ranges, AOI, and sizes tailored to your system

Spectrum Transmission & Reflection

SOT dichroic filters are engineered to provide high average transmission (Tave ≥95%) in the passband while achieving high reflectivity (R ≥98%) in the stopband. Designs are optimized for a 45° angle of incidence (AOI) as standard, with alternative AOIs available upon request.

Customization available: If standard models do not meet your requirements, bespoke spectral designs can be produced to match specific wavelength boundaries, bandwidths, and system geometries.

Coating Quality & Environmental Reliability

All dichroic filters undergo rigorous testing to ensure durability and reliability:

- Adhesion Test (MIL-C-675C) – No blistering or peeling after repeated tape removal

- Thermal Cycling – −62 °C to +71 °C with no coating detachment

- Abrasion Resistance (MIL-C-675C / CCC-C-440) – No damage after 25 cycles at 1.0 lb load

- Humidity Test – 95–100% RH at 49 °C for 24 hours with no defects

- Solvent Resistance – Stable after acetone and alcohol exposure

- Salt Spray Test – 100 hours at 35 °C, 5% salt concentration with no coating degradation

Standard Specifications (AOI = 45°)

| Model | Transmission (%) | Transmission Band (nm) | Reflectivity (%) | Reflection Band (nm) |

|---|---|---|---|---|

| DM450 | Tave ≥95% | 465–680 | R ≥98% | 380–445 |

| DM505 | Tave ≥95% | 515–700 | R ≥98% | 450–490 |

| DM550 | Tave ≥95% | 560–700 | R ≥98% | 450–540 |

| DM565 | Tave ≥95% | 575–700 | R ≥98% | 450–555 |

| DM590 | Tave ≥95% | 603–700 | R ≥98% | 450–580 |

| DM600 | Tave ≥95% | 622–700 | R ≥98% | 450–590 |

| DM635 | Tave ≥95% | 650–700 | R ≥98% | 450–630 |

| DM700 | Tave ≥95% | 665–700 | R ≥98% | 450–640 |

| DM770 | Tave ≥95% | 715–800 | R ≥98% | 450–685 |

| DM500 (SP) | Tave ≥95% | 440–485 | R ≥98% | 515–700 |

Additional wavelengths, AOIs, substrates, and sizes available upon request.

Typical Applications

- Spectrometers – Isolating spectral bands for accurate analysis

- Microscopy – Fluorescence excitation/emission separation

- Laser Systems – Combining or separating laser wavelengths

- Imaging Systems – Precise spectral isolation in cameras

- Astronomical Instruments – Targeted wavelength selection for enhanced observation