Description: Cooled Long-Wave Infrared lenses (Cooled LWIR Lens) are used in high-performance thermal imaging systems within the 8-12 µm spectrum. They provide exceptional detail and sensitivity under extreme conditions.

Optical Module Characteristics: Constructed from specialized materials like Zinc Selenide or Germanium, these lenses include precise thermal management to operate effectively at cryogenic temperatures.

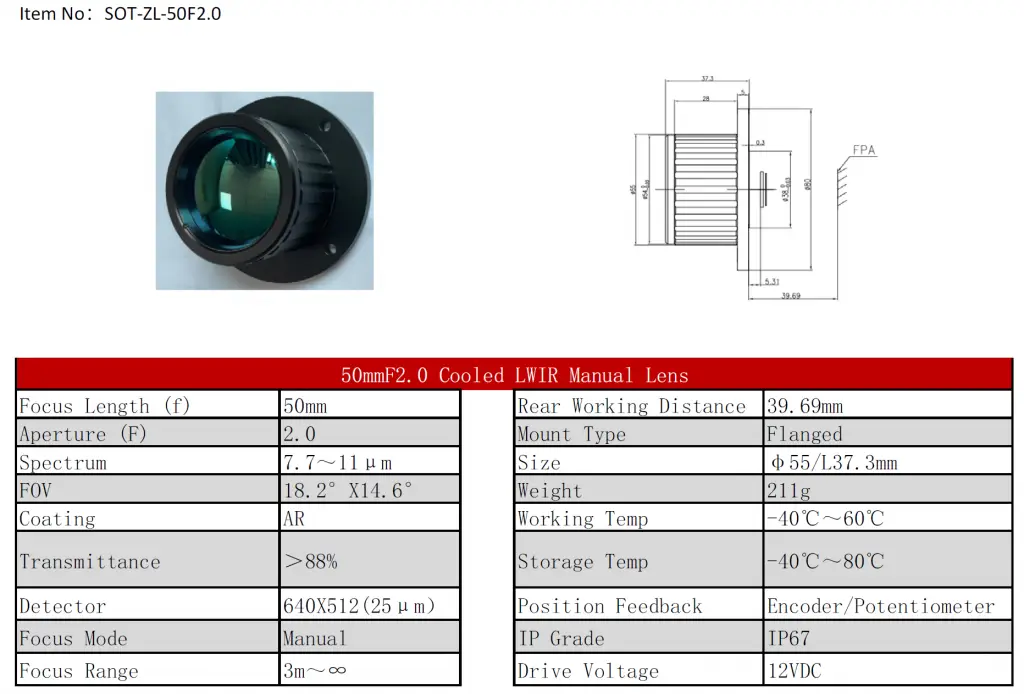

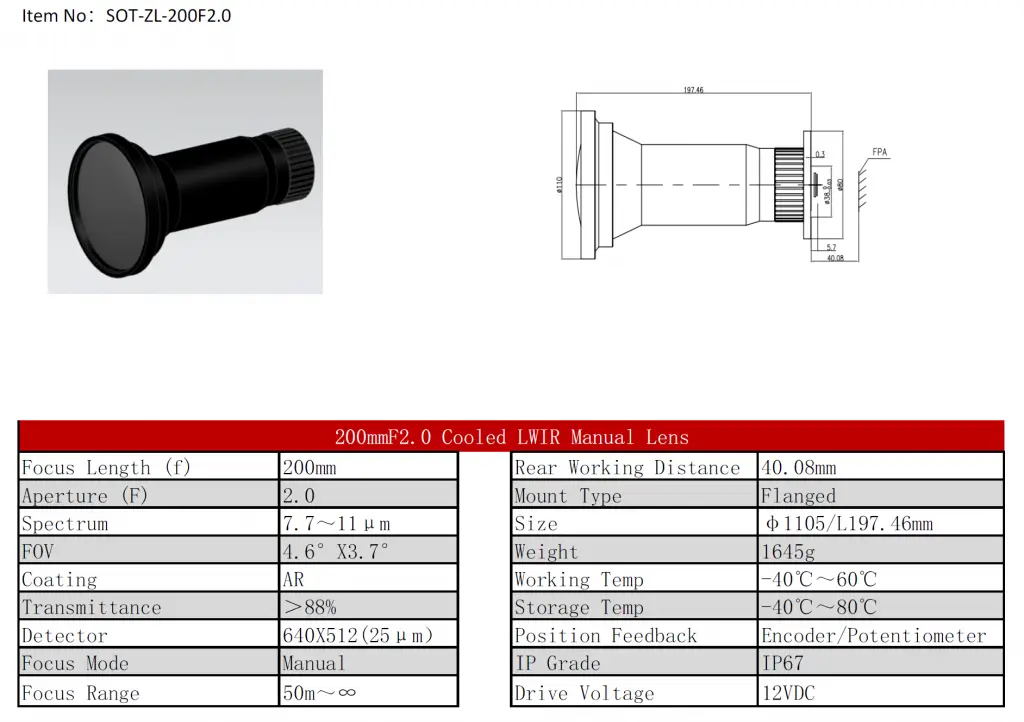

Key Optical Parameters of Cooled LWIR Lens:

- Focal Length: Ranges widely based on use-case requirements.

- Aperture: Generally large to enhance light collection capabilities.

- Spectrum FOC: Tailored for the 8-12 µm range.

- Transmittance: Extremely high, often featuring multi-layer anti-reflective coatings.

- Detector Compatibility: Used with cooled detectors like MCT.

- Mount Type: Heavy-duty mounts to support the lens and cooling system.

Applications Cooled LWIR Lens: Critical for defense and security, maritime and aerial surveillance, and environmental monitoring where high thermal contrast is required.

Selecting a Cooled Long-Wave Infrared (LWIR) lens involves several important considerations to ensure optimal performance in thermal imaging applications. Here’s a step-by-step guide on what to consider:

- Detection Needs: Determine what you will be using the lens for. Cooled LWIR lenses are typically used in applications requiring high sensitivity, such as surveillance, military, and advanced scientific research.

- Focal Length: Choose the appropriate focal length based on your required field of view and distance to the target. A longer focal length lens provides a narrower field of view and is suitable for long-range detection, while a shorter focal length offers a wider field of view for shorter ranges.

- F-Number: Consider the lens’ f-number, which indicates its light-gathering ability. Lower f-numbers provide better performance in low-light conditions but can be more expensive.

- Optical Resolution: Ensure the lens resolution matches or exceeds the resolution of the detector to maximize the image quality.

- Material and Coatings: Look for materials and coatings that are optimized for high transmission in the LWIR range (typically 8-14 microns). Anti-reflective coatings are crucial for minimizing loss of signal.

- Compatibility: Check the mechanical and optical compatibility with your cooled LWIR camera, including mount type and sensor size.

- Environmental Considerations: Since these lenses are used in cooled systems, ensure they can operate under the environmental conditions they will be exposed to. Consider factors like operating temperature range and resistance to moisture or dust.

- Durability and Quality: High-quality construction is essential for maintaining performance in varying conditions and over time. The build quality can significantly affect the lens’s longevity and reliability.

- Budget: Finally, consider your budget. Cooled LWIR systems, including lenses, are typically more expensive than their uncooled counterparts due to the advanced technology and materials required.

By taking these factors into account, you can select a Cooled LWIR lens that best fits your specific requirements and ensures optimal performance in your thermal imaging tasks. If you need specific product recommendations or further technical details, feel free to ask!

Shape Optics’ unwavering commitment to excellence propels the advancement of Infrared Optical (IR Optical-Cooled LWIR Lens) Modules. With Shape Optics, the unseen is revealed, and mysteries are deciphered. Enhance your innovation trajectory with Shape Optics’ Infrared Optical Module Solutions—redefining the limits of perception. Contact Shape Optics today to begin a transformative journey with our custom Infrared Optical (IR Optical) Module imaging solutions.