Aspherization is one of the most powerful techniques in optical design for improving image quality. A well-placed aspheric surface can significantly reduce aberrations such as spherical aberration, coma, and astigmatism—often with fewer elements, lower weight, and improved manufacturability.

However, not every surface benefits equally from being made aspheric. Randomly adding aspheres can:

- Increase design complexity

- Slow optimization

- Raise manufacturing cost with little performance gain

This article introduces a fast and systematic method in Zemax OpticStudio to identify which surfaces in a design are the best candidates for aspherization.

Example System: Cooke Triplet Derivative

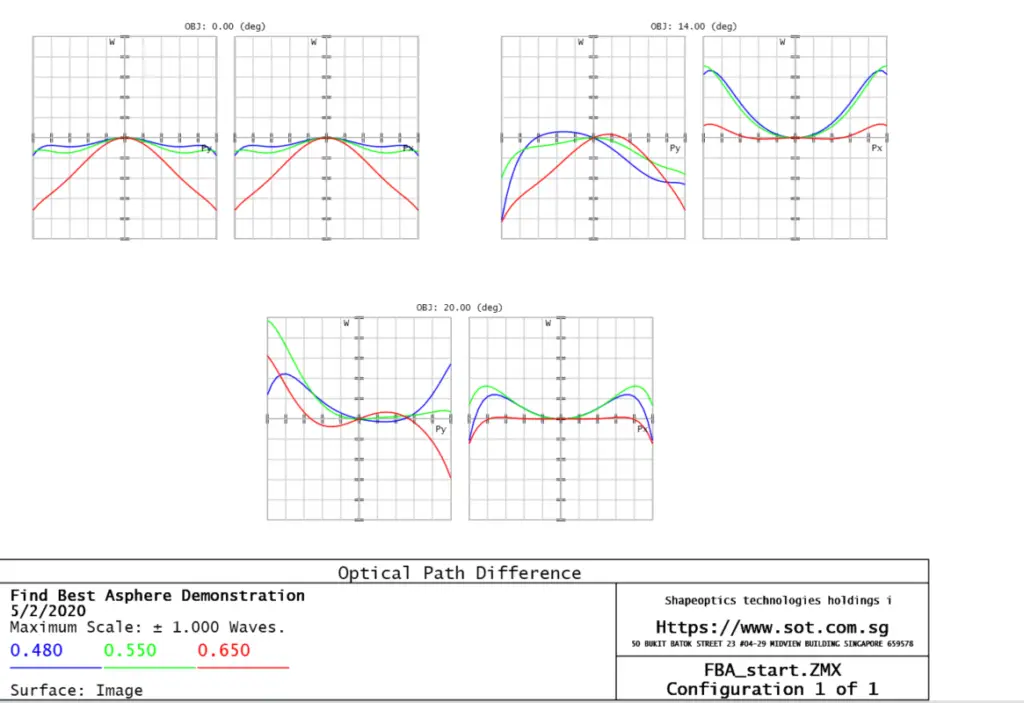

The example design is a Cooke triplet derivative, optimized for minimum RMS wavefront error.

Key characteristics:

- All radii and thicknesses are variable

- The last surface radius is constrained by an F/# solve

- System speed is maintained at f/5 throughout optimization

This type of system is ideal for demonstrating asphere selection because:

- It is well understood

- Aberrations are distributed across multiple surfaces

- Only a subset of surfaces will provide strong aspheric leverage

The Asphere Candidate Identification Tool

OpticStudio provides a tool that rapidly evaluates which surfaces will benefit most from aspherization.

What the Tool Does

The tool:

- Analyzes a range of surfaces

- Tests each surface’s potential performance improvement if converted to an asphere

- Ranks surfaces based on effectiveness

You can specify:

- Start surface

- Stop surface

- Maximum polynomial order (e.g., even aspheric terms)

This allows quick exploration without manually converting and testing each surface.

Criteria for Asphere Candidate Selection

For a surface to be considered a valid asphere candidate, it must meet all of the following conditions:

✔ Surface type must be Standard

✔ No conic constant already applied

✔ Surface must lie between air and glass

✔ Cemented surfaces are excluded (usually poor asphere choices)

✔ Curvature must be:

- A variable, or

- Controlled by a Marginal Ray Angle solve, or

- Controlled by an F/# solve

Surfaces that do not meet these criteria are automatically ignored by the tool.

Why These Conditions Matter

Air–Glass Interfaces

Aspheric surfaces are most effective at:

- Strong refractive boundaries

- Locations with significant ray height variation

Cemented surfaces typically:

- Have reduced refractive power

- Offer limited aberration correction leverage

Variable or Solved Curvature

If the surface curvature cannot change:

- The optimizer cannot fully exploit aspheric terms

- Performance improvement will be limited

Practical Workflow for Aspherization

A recommended workflow is:

- Optimize the all-spherical design first

- Run the asphere candidate identification tool

- Select the top-ranked surface

- Convert only that surface to an asphere

- Re-optimize

- Repeat if additional improvement is required

This approach:

- Minimizes design risk

- Keeps manufacturability under control

- Achieves maximum benefit with minimal complexity

Benefits of This Approach

- Rapid identification of high-impact surfaces

- Avoids unnecessary aspheres

- Faster optimization convergence

- Lower fabrication cost

- Cleaner, more robust designs

In many systems, one well-chosen asphere can outperform multiple poorly chosen ones.

Key Takeaways

- Not all surfaces benefit equally from aspherization

- Air–glass, high-power surfaces are usually best

- Cemented interfaces are poor asphere candidates

- Use analytical tools before adding aspheres

- Start spherical, then add aspheres strategically

Aspherization is most effective when it is deliberate and data-driven, not trial-and-error.