Optical coatings are an increasingly critical component of modern optical systems such as microscopes, telescopes, cameras, and laser systems. As optical designs become more complex, the ability to predict and evaluate coating effects before fabrication has become essential for optical designers.

This article demonstrates how common Anti-Reflection (AR) coatings are used across typical spectral bands and how coating selection directly impacts system performance. In practice, optical coatings are always application-specific, taking into account factors such as wavelength or wavelength band, polarization state, angle of incidence, environmental durability, and laser power.

Example: Anti-Reflection Coatings in a Fiber-Coupling Lens Design

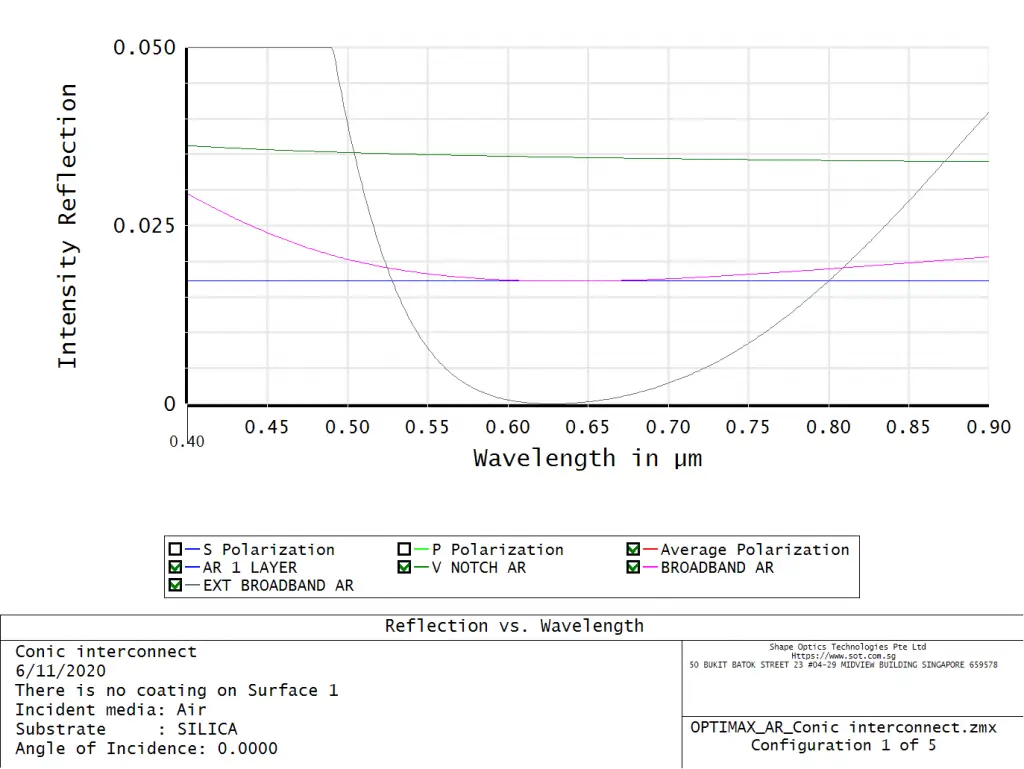

To illustrate the performance differences between AR coatings, consider the optical design example below.

The coating definitions used in this design can be found in the encrypted coatings library within ZEMAX.

This system consists of a singlet lens used to couple light between two single-mode fibers, making it a sensitive and practical example of coating performance. Both the front and rear surfaces of the lens are treated with Anti-Reflection coatings.

Each configuration in the design applies a different AR coating, allowing direct comparison of how coating choice influences:

- Surface reflectance

- Optical transmission

- Coupling efficiency

The resulting plots clearly show how different coatings reduce reflected light at the lens interfaces, improving overall system throughput.

The figure below compares multiple coating configurations applied to the same optical design. Each configuration corresponds to a different coating recipe originally defined by OPTIMAX, for which Shape Optics can provide equivalent or customized performance solutions.

These comparisons highlight how advanced AR coatings can significantly outperform simple single-layer designs, especially over broader wavelength ranges.

Description of Common Anti-Reflection Coatings

Single-Layer AR Coating

OPTIMAX-SLMGF2

A single-layer magnesium fluoride (MgF₂) coating.

- Simplest AR design

- Cost-effective

- Best suited for narrowband or less demanding applications

Narrowband (V-Notch) AR Coatings

OPTIMAX-Vxxx-1_N

- Designed for a specific target wavelength

- Lower residual reflectance than single-layer coatings

- Ideal for laser or monochromatic applications

Broadband Visible AR Coatings

OPTIMAX-VISBBAR-1_N

- Optimized for 400–700 nm

- Suitable for visible imaging systems

- Good balance between bandwidth and reflectance

Extended Broadband AR Coatings: OPTIMAX-XBBAR-1_N

- Optimized for 450–900 nm

- Covers visible and near-infrared bands

- Ideal for multispectral or broadband systems

Conclusion

Anti-Reflection coatings play a vital role in maximizing optical system performance. The example presented demonstrates how coating selection can dramatically influence reflection losses and overall efficiency—especially in systems sensitive to throughput, such as fiber-coupled optics.

By modeling coating effects during the design phase, optical engineers can make informed decisions that reduce risk and improve final system performance.