What Is Infrared and How It Interacts with Optical Materials?

Infrared (IR) is a type of electromagnetic radiation that exists just beyond the red end of the visible light spectrum. Although invisible to the human eye, infrared radiation is something we experience every day — as heat.

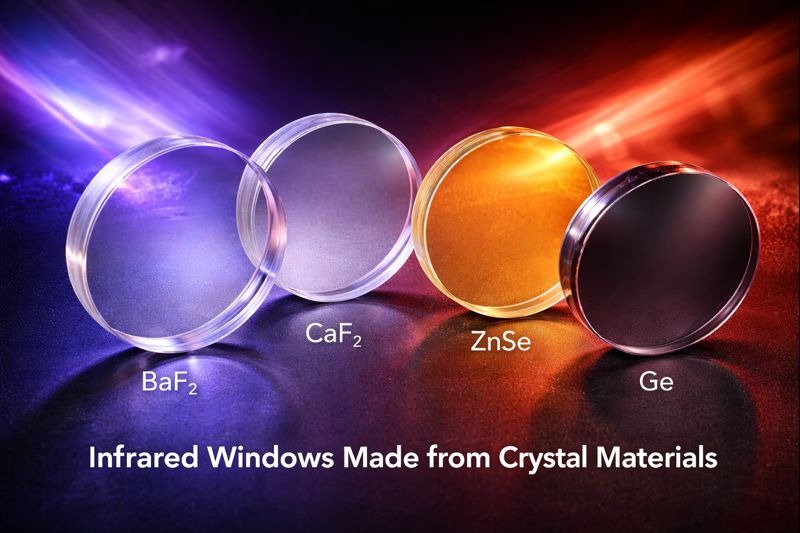

Understanding infrared is essential when selecting materials like germanium, silicon, ZnSe, ZnS, and CaF₂ for infrared windows and lenses. Each material interacts with infrared differently, and that determines its suitability for thermal imaging or laser systems.

What Is Infrared?

Infrared is electromagnetic radiation with wavelengths longer than visible light.

- Visible light: 0.4–0.7 µm

- Infrared: 0.7 µm to 1000 µm

Every object above absolute zero (-273°C) emits infrared radiation. The hotter the object, the stronger the infrared emission.

This is why thermal cameras can “see” heat — they detect emitted infrared energy instead of reflected visible light.

Infrared Regions Used in Imaging

Infrared is divided into several bands:

| Region | Wavelength | Common Use |

|---|---|---|

| NIR | 0.7–1.4 µm | Fiber optics, night vision |

| SWIR | 1–3 µm | Industrial inspection |

| MWIR | 3–5 µm | High-sensitivity thermal imaging |

| LWIR | 8–12 µm | Most thermal cameras |

Most thermal imaging systems operate in:

- MWIR (3–5 µm)

- LWIR (8–12 µm)

How Infrared Interacts with Materials

When infrared radiation hits a material, three things can happen:

- Transmission – wave passes through

- Reflection – wave bounces off

- Absorption – energy converts into heat

For infrared optics, we want:

- High transmission

- Controlled reflection

- Minimal absorption

This behavior depends on the material’s atomic structure and bandgap energy.

Infrared Optical Materials Explained

1. Germanium (Ge)

Germanium is one of the most common materials used in LWIR thermal imaging systems.

It allows low-energy infrared photons to pass but absorbs higher-energy visible light due to its bandgap properties. Because of its high refractive index, uncoated germanium reflects ~36% per surface — AR or DLC coating is essential.

Features

- Transmission: 2–14 µm

- Excellent in LWIR (8–12 µm)

- High refractive index (~4.0)

- Blocks visible light

Applications

- Thermal camera lenses

- Infrared windows

- Defense imaging systems

2. Silicon (Si)

Silicon is widely used for MWIR applications. Similar to germanium, silicon’s bandgap allows infrared transmission while blocking visible wavelengths.

Features

- Transmission: 1–6 µm

- Excellent for MWIR (3–5 µm)

- Strong and lightweight

- Blocks visible light

Applications

- MWIR optics

- Infrared laser systems

- Harsh-environment windows

3. Zinc Selenide (ZnSe)

ZnSe offers broad infrared transmission and also passes visible light. It has a wider transmission window and lower surface reflection compared to germanium.

Features

- Transmission: 0.6–16 µm

- Good for MWIR and LWIR

- Lower refractive index (~2.4)

- Visible alignment possible

Applications

- CO₂ laser optics (10.6 µm)

- Infrared lenses

- Medical laser systems

Zinc Sulfide (ZnS)

ZnS is commonly used in multi-spectral imaging systems. Allows both visible and infrared wavelengths to pass, enabling multi-spectral systems.

Features

- Transmission: 0.4–12 µm

- Visible + IR capable

- Good mechanical strength

Applications

- Missile domes

- Military optics

- Multi-spectral imaging systems

5. Calcium Fluoride (CaF₂)

CaF₂ is known for its very broad transmission range. Low dispersion and broad transparency make it ideal for UV–IR optical systems.

Features

- Transmission: 0.2–8 µm

- Low refractive index (~1.4)

- Low absorption

- More fragile than Ge or Si

Applications

- Spectroscopy

- Scientific instruments

- UV to IR optical systems

Material Comparison Overview

| Material | MWIR | LWIR | Visible Transmission | Refractive Index | Typical Use |

|---|---|---|---|---|---|

| Germanium | Good | Excellent | No | ~4.0 | LWIR thermal imaging |

| Silicon | Excellent | Poor | No | ~3.4 | MWIR systems |

| ZnSe | Good | Excellent | Yes | ~2.4 | CO₂ laser optics |

| ZnS | Good | Good | Yes | ~2.2 | Multi-spectral |

| CaF₂ | Good | Limited | Yes | ~1.4 | UV–IR systems |

Why Coatings Are Important

Many infrared materials reflect significant energy:

- Germanium reflects ~36% without coating

- Glass reflects ~4% per surface

Optical coatings such as:

- AR (Anti-Reflective)

- BBAR (Broadband AR)

- DLC (Diamond-Like Carbon)

are used to improve transmission and durability.

Summary

Infrared imaging depends not only on detectors and electronics — but fundamentally on the right optical material.

Each material interacts with infrared differently due to its physical structure and bandgap properties. Selecting the correct substrate ensures:

- Maximum transmission

- Minimal signal loss

- Reliable performance in your wavelength range

If you’re designing a thermal imaging system or infrared window, choosing the right material is the first critical step.