Laser Radar Windows are high-performance optical windows specifically designed for LiDAR (Light Detection and Ranging) systems. These windows provide a protective optical interface while ensuring exceptionally high transmission of the operating laser wavelength and minimal signal distortion.

LiDAR systems used in autonomous vehicles, mapping, navigation, and environmental monitoring rely on optical windows that maintain clarity, durability, and spectral accuracy. SOT’s laser radar windows are manufactured using advanced coating technologies to achieve excellent transmission at common LiDAR wavelengths—850 nm, 905 nm, 940 nm, and 1550 nm—while resisting abrasion, humidity, temperature cycling, and chemical exposure.

Key Features

- Optimized for LiDAR Systems – Engineered for laser radar and distance-measurement applications with minimal signal loss

- High Transmittance – Tave ≥ 99% at key LiDAR wavelengths for maximum system efficiency

- Multi-Wavelength Support – Standard designs for 850 nm, 905 nm, 940 nm, and 1550 nm

- Hard Coating Durability – Scratch-resistant, environmentally robust coatings for long service life

- Customizable Optical Properties – Wavelength band, coating design, AOI, and size tailored to your system

- Reliable in Harsh Environments – Stable optical performance in outdoor, automotive, and industrial conditions

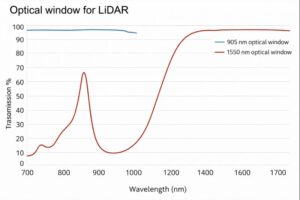

Spectrum Transmission

Standard laser radar windows are optimized for narrow LiDAR operating bands with flat, high transmission across the working wavelength range.

Custom transmission ranges and AOI designs are available upon request to match your LiDAR architecture.

Coating Quality & Environmental Reliability

All laser radar windows are qualified to stringent standards:

- Adhesion (MIL-C-675C) – No blistering or peeling after repeated tape removal

- Thermal Cycling – −62 °C to +71 °C with no coating detachment

- Abrasion Resistance (MIL-C-675C / CCC-C-440) – No surface damage after 25 cycles at 1.0 lb load

- Humidity Resistance – 95–100% RH at 49 °C for 24 hours without defects

- Solvent Resistance – Stable after acetone and alcohol exposure

- Salt Spray Test – 100 hours at 35 °C, 5% salt concentration with no degradation

Standard Specifications

| Model | AOI | Wavelength Range (nm) | Transmittance | Coating Type | Notes |

|---|---|---|---|---|---|

| 850 nm Window | 0° | 800–900 | Tave ≥ 99% | Hard Coating | Customizable |

| 905 nm Window | 0° | 890–920 | Tave ≥ 99% | Hard Coating | Customizable |

| 940 nm Window | 0° | 900–980 | Tave ≥ 99% | Hard Coating | Customizable |

| 1550 nm Window | 0° | 1500–1600 | Tave ≥ 99% | Hard Coating | Customizable |

Typical Applications

- Autonomous Vehicles & ADAS – High-accuracy LiDAR sensing and object detection

- Geophysical Surveying – Terrain mapping and environmental analysis

- Industrial Automation – Laser-based inspection, sorting, and measurement systems

- Defense & Security – Surveillance and laser radar monitoring

- Environmental Monitoring – Vegetation analysis, forestry, and pollution tracking

- Aerospace – Airborne LiDAR for navigation, safety, and terrain mapping

Need a custom laser radar window?

Contact us with your operating wavelength, AOI, window size, environmental conditions, and coating requirements for a tailored LiDAR solution.