Key Features:

- Excellent optical uniformity

- High resistance to acid and alkali corrosion

- Stable chemical properties

- Consistent refractive index and uniformity

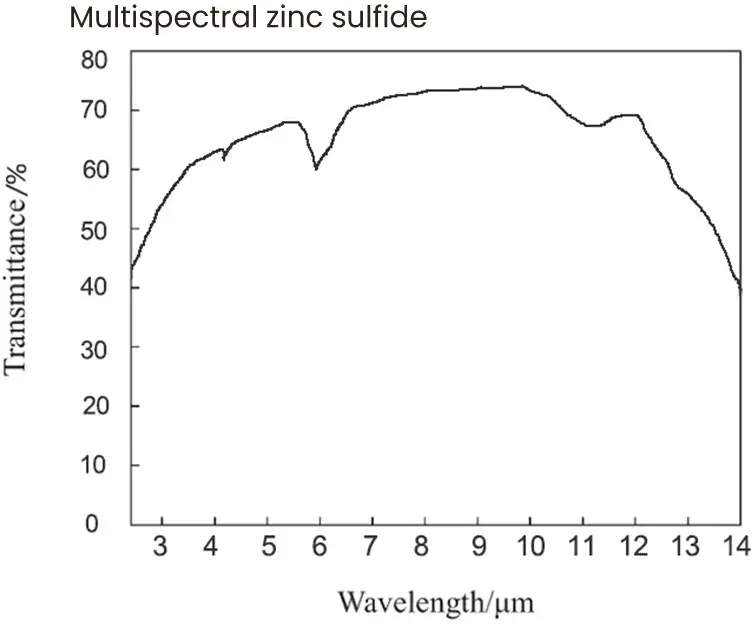

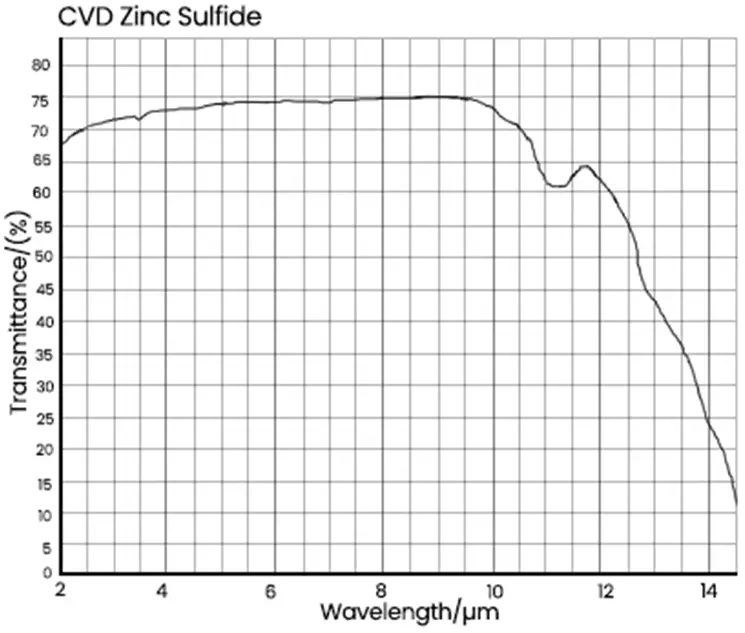

- High transmittance and reflectance in the visible spectrum

Description: ZnS (Zinc Sulfide) is a wide-bandgap semiconductor material with excellent transparency in the infrared spectrum. It is a crucial infrared optical material with outstanding chemical and physical properties. ZnS crystals are ideal for infrared lenses, laser windows, and thermal imaging systems. CVD-grown ZnS crystals, after hot isostatic pressing (HIP) treatment, exhibit multi-spectral properties, enhancing IR transmittance and visible light performance. They offer excellent transmission over the entire range from 0.4 µm to 12 µm.

Physical Properties:

| Property | Specification |

|---|---|

| Density | 4.09 g/cm³ |

| Hardness | 150-160 kg/mm² |

| Diameter Tolerance | +0.0/-0.1 mm |

| Length Tolerance | ±0.1 mm |

| Surface Flatness | λ/8 @ 632.8 nm |

| Parallelism | < 1 arc minute |

| Surface Quality | 40-20 Scratch/Dig |

| Clear Aperture | > 90% |

| Chamfer | < 0.25 x 45° |

| Coating | Custom designs available |

Optical Properties:

| Property | Specification |

|---|---|

| Transmission Range | 0.4-12 µm |

| Refractive Index | 2.356 @ 10.6 µm |

| Absorption Coefficient | < 0.0005 cm⁻¹ @ 10.6 µm |

| Optical Density (OD) | 1.85 |

| Transmission (%) | > 65% @ 10.6 µm |

Standard Specifications:

| Property | Specification |

|---|---|

| Orientation | Random |

| Diameter | Up to 6 inches |

| Thickness | 0.5 to 10 mm |

| Surface Quality | 40/20 Scratch/Dig (MIL-PRF-13830B) |

| Surface Flatness | λ/8 @ 632.8 nm |

| Parallelism | < 1 arc minute |

| Perpendicularity | < 5 arc minutes |

| Coating | AR/AR, AR/DLC, and other custom coatings |

Other Properties:

- High chemical durability ensures longevity in harsh environments.

- Excellent thermal stability supports high-power laser operations.

Applications:

- Infrared lenses and windows

- High-power laser optics

- Thermal imaging systems

- Medical and scientific applications

- Astronomy and IR night vision

Processing and Handling:

- ZnS crystals require careful handling to avoid surface damage and contamination.

- Use gloves or finger cots when handling ZnS components.

- Store in a clean, dry environment with temperature control to prevent thermal shock.

- Ensure proper cleaning procedures to maintain optical quality.

Why Choose Shape Optics:

- We provide high-quality ZnS crystals with precise specifications and excellent optical properties.

- Our crystals undergo stringent quality control to ensure reliability and performance in demanding applications.

- Customization options available to meet specific requirements.

Shape Optics Strength and Capabilities:

- Expertise in crystal growth and fabrication techniques.

- Advanced metrology and inspection facilities to ensure superior product quality.

- Comprehensive support and consultation services to assist in the integration of ZnS crystals into various optical systems.

- Commitment to innovation and excellence in the field of optical engineering.