Key Features

- Broad absorption bands in the 1.2-1.6 μm range

- High damage threshold

- Excellent thermal stability

- Low cost and easy fabrication

- Suitable for eye-safe 1.54 μm Er glass lasers

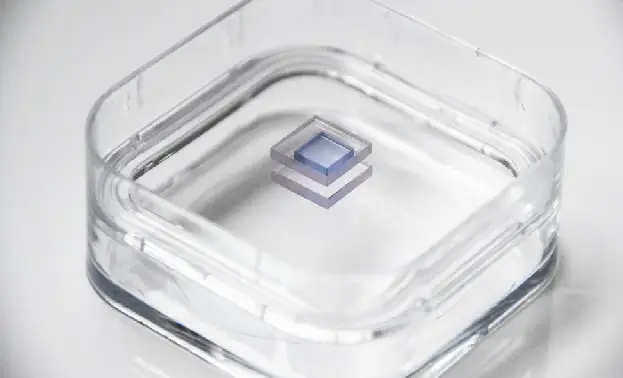

Description Co2+(Cobalt-doped magnesium aluminate spinel) crystals, commonly referred to as Co, are relatively new materials used in laser applications. These crystals are specifically designed for passive Q-switching in 1.2-1.6 μm lasers, making them ideal for eye-safe 1.54 μm Er glass lasers. Cocrystals can also operate at 1.44 μm and 1.34 μm laser wavelengths, providing a cost-effective solution for developing compact, low-cost nanosecond and sub-nanosecond pulse lasers. With their broad application range, Cocrystals are becoming increasingly popular in various laser systems.

Physical Properties

- Dimensions Tolerance: ±0.5 mm

- Surface Quality: <λ/8 @ 632 nm

- Wavefront Distortion: <λ/4 @ 632 nm

- Laser Damage Threshold: 30 MW/cm² (1.064 μm, 10 ns)

- Coating: AR/AR @ 1540 nm, R < 0.2%; AR/AR @ 1340 nm, R < 0.2%

- Maximum Size: Diameter (3-15) x (3-50) mm

Optical Properties

- High transmission aperture (>90%)

- Low absorption and scattering losses

- Excellent optical homogeneity

- High optical damage threshold

- Suitable for both pulsed and continuous wave (CW) laser applications

Standard Specifications

| Property | Specification |

|---|---|

| Dimensions Tolerance | ±0.5 mm |

| Surface Quality | <λ/8 @ 632 nm |

| Wavefront Distortion | <λ/4 @ 632 nm |

| Laser Damage Threshold | 30 MW/cm² (1.064 μm, 10 ns) |

| Coating | AR/AR @ 1540 nm, R < 0.2%; AR/AR @ 1340 nm, R < 0.2% |

| Maximum Size | Diameter (3-15) x (3-50) mm |

| Surface Flatness | 10-5 |

| Parallelism | 10″ |

| Perpendicularity | 5′ |

Other Properties

- Highly durable and robust, ensuring long-term stability and performance.

- Can be easily fabricated into various shapes and sizes to meet specific application requirements.

Applications

- Passive Q-switching for 1.2-1.6 μm lasers

- Eye-safe 1.54 μm Er glass lasers

- Compact, low-cost nanosecond and sub-nanosecond pulse lasers

- Defense and medical applications requiring high-repetition-rate lasers

- High-energy laser systems for industrial and scientific research

Processing and Handling Cocrystals require precise cutting, polishing, and coating to achieve the desired specifications. At Shape Optics, we utilize advanced fabrication techniques to ensure high-quality and performance. Proper handling and storage conditions are essential to maintain the crystal’s properties and extend its lifespan.

Why Choose Shape Optics Shape Optics is a leading provider of high-quality Cocrystals, offering customized solutions to meet your specific needs. Our commitment to quality, innovation, and customer satisfaction ensures that you receive the best products and services in the industry.

Shape Optics Strength and Capabilities Shape Optics leverages state-of-the-art manufacturing processes and expertise in crystal growth, cutting, polishing, and coating to deliver superior Cocrystals. Our dedication to excellence and continuous improvement ensures that we provide the highest performance materials for your laser applications. Partner with us to benefit from our extensive experience and unwavering commitment to quality.