Optical Coating Technician

- Job Summary:

- Implement optical lens coating design strategies, manage machinery and work with other employees to meet client needs for optical lenses, mirrors and other optical devices.

- Participate in all aspects of coating, including optical design, process development and documentation, analysis, cleaning and inspection.

- Responsible for oversight of equipment usage and hands-on work on preventative maintenance, minor repairs and improvements to optical lens coating machinery.

- Key Responsibilities (must be able to perform with or without accommodation):

- Thoroughly inspect all “cleaned for Coating” optics to ensure surface to be coated is free of any defect

- Read blueprints and follow the specifications of each job ensuring compliance with the customer’s needs

- Operate equipment including crystal and optical monitors

- Run “Optical Thin-Film Coating Programs” on computer and model all optical coating

- Reliably calculate work to monitor ratios; able to analyze problem optical lens coating and modify formula to run in specific machines

- Adjust existing formulas to various glass index changes, and move optical lens coatings up or down in wavelengths

- Physical Requirements:

- Normal factory environment requiring walking, talking, sitting, standing, and seeing

- Excellent vision

- Ability to lift 35 pounds frequently and up to 75 pounds occasionally

- Ability to climb ladders

- Ability to enter product parameters into PC based control systems

Would like to know more about our optical lens coating capabilities, please refer to optical coating design and manufacturing.

Would like to find more jobs @ shapeoptics, please refer to “Join Our Team“.

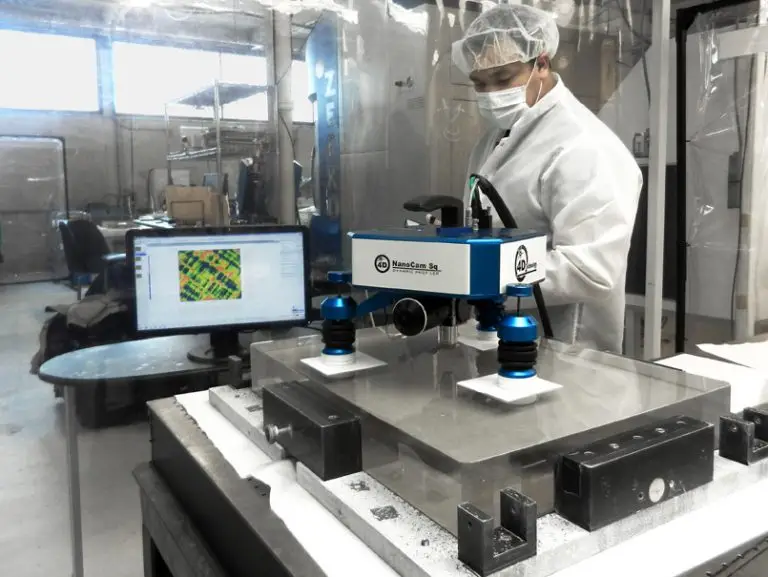

About our optical thin-film coating clean room

Our optical lens coating Cleanrooms maintain particulate-free air through the use of either HEPA or ULPA filters employing laminar or turbulent air flow principles. Laminar, or unidirectional, air flow systems direct filtered air downward in a constant stream. Laminar air flow systems are typically employed across 100% of the ceiling to maintain constant, unidirectional flow. Laminar flow criteria is generally stated in portable work stations (LF hoods), and is mandated in ISO-1 through ISO-4 classified cleanrooms.